Method for packaging wafer level solid-state image sensor

A technology of solid-state image and packaging method, which is applied in the fields of decorative arts, gaseous chemical plating, microstructure devices, etc., and can solve the problem that the flatness of glass wafers and silicon wafers of image sensors is difficult to control, and the flatness of glass wafers and silicon wafers Difficult to control inter-chip spacing, by-product contamination of the chip surface, etc., to achieve an excellent planar optical window, which is beneficial to performance and avoids the distortion of image signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

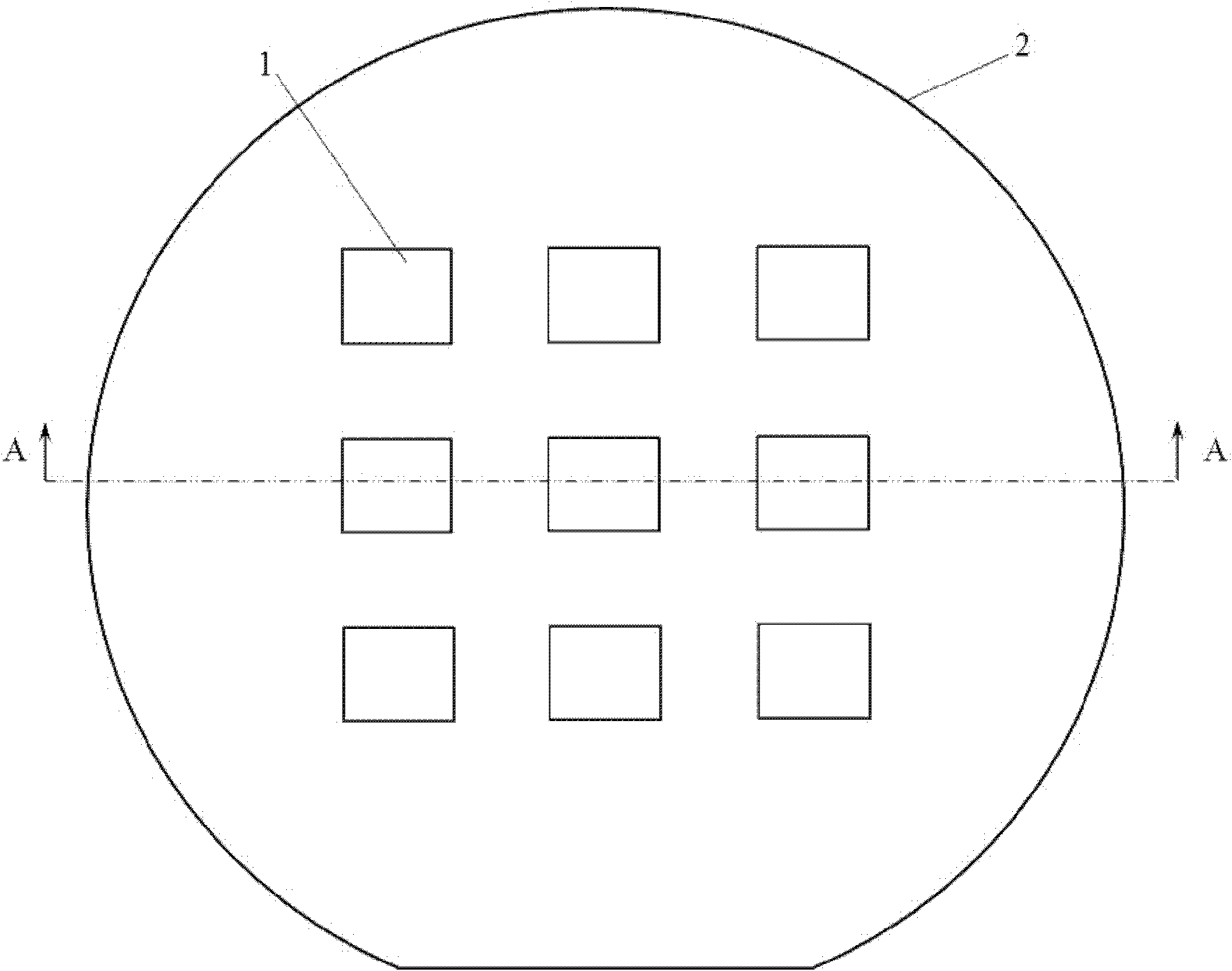

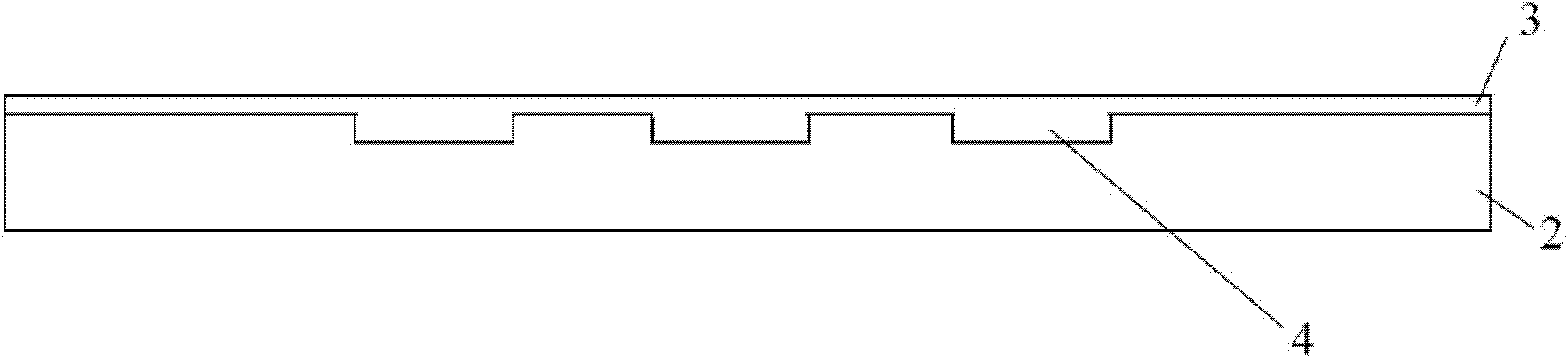

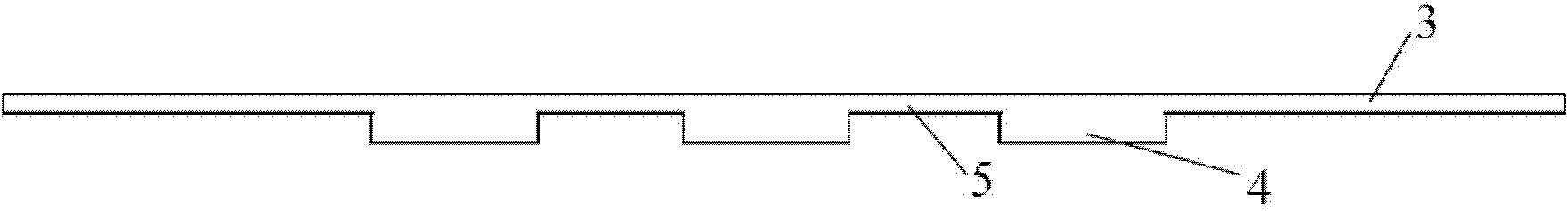

[0019] A packaging method for a wafer-level solid-state image sensor, comprising the following steps: a first step, etching a microgroove ring array on a silicon wafer (such as a 4-inch wafer), thereby obtaining a silicon wafer mold; the microcavity is circular or square, and the process for preparing the pattern structure on the silicon wafer is one of wet etching process, reactive ion etching (RIE) process or deep reactive ion etching (DRIE). In the second step, the borosilicate glass wafer is bonded to the above-mentioned silicon wafer mold under vacuum (5E~5Pa) conditions, so that the micro-groove ring of the silicon wafer mold is sealed; in the present invention, the glass is Pyrex7740 For glass, the bonding method used is anodic bonding, and the anodic bonding conditions are: voltage 600V-800V, temperature 300°C-500°C. The third step is to heat the bonded disc above the softening point of the glass and keep it warm for a certain period of time. The atmospheric pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com