Mechanical winch automatic reversing cable distributor mechanism

A technology of automatic reversing and cable puller, which is applied in the direction of clockwork mechanism and hoisting device, which can solve the problems of double-threaded screw type jamming and complicated system, and achieve the effect of compact mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

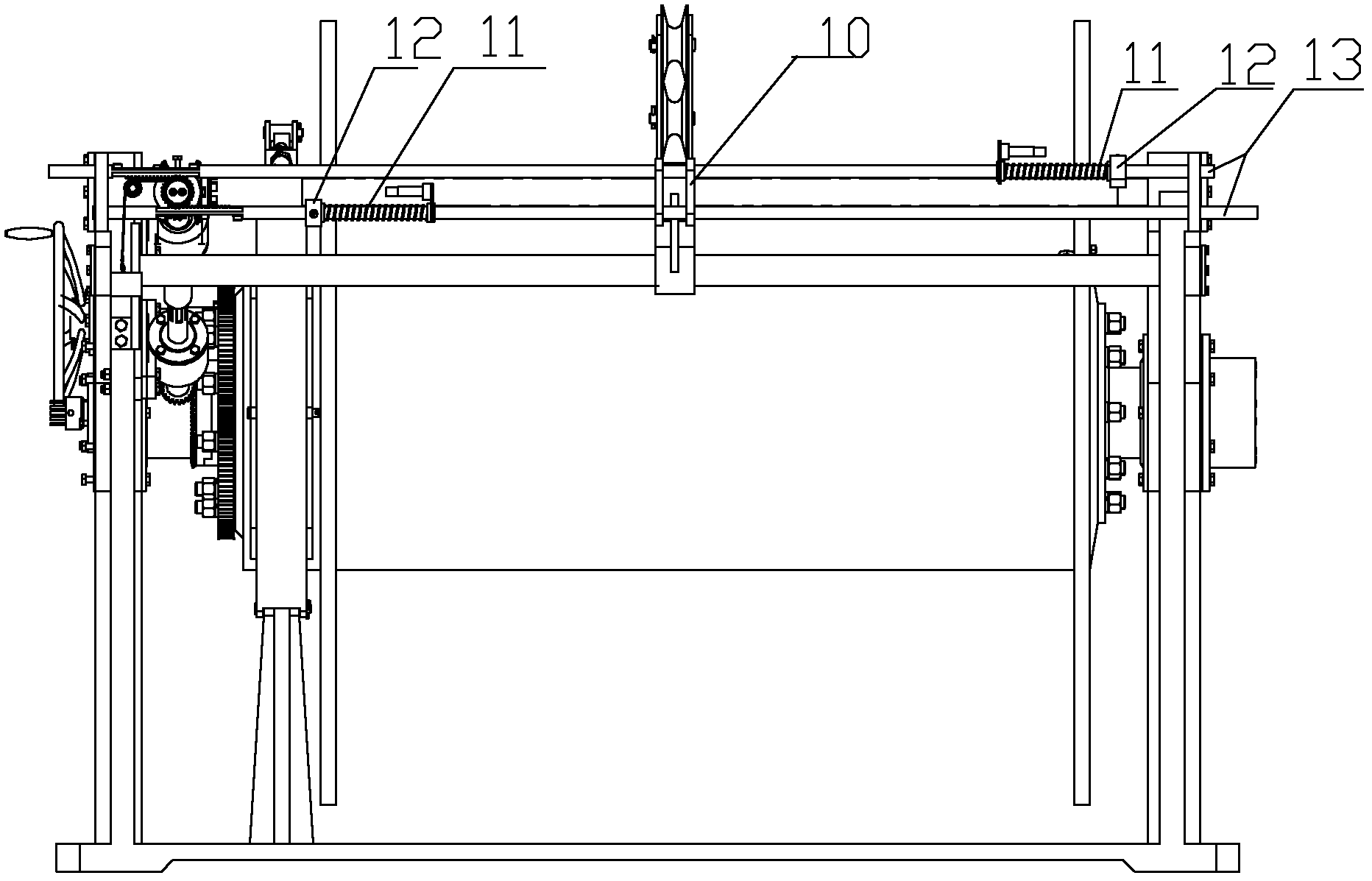

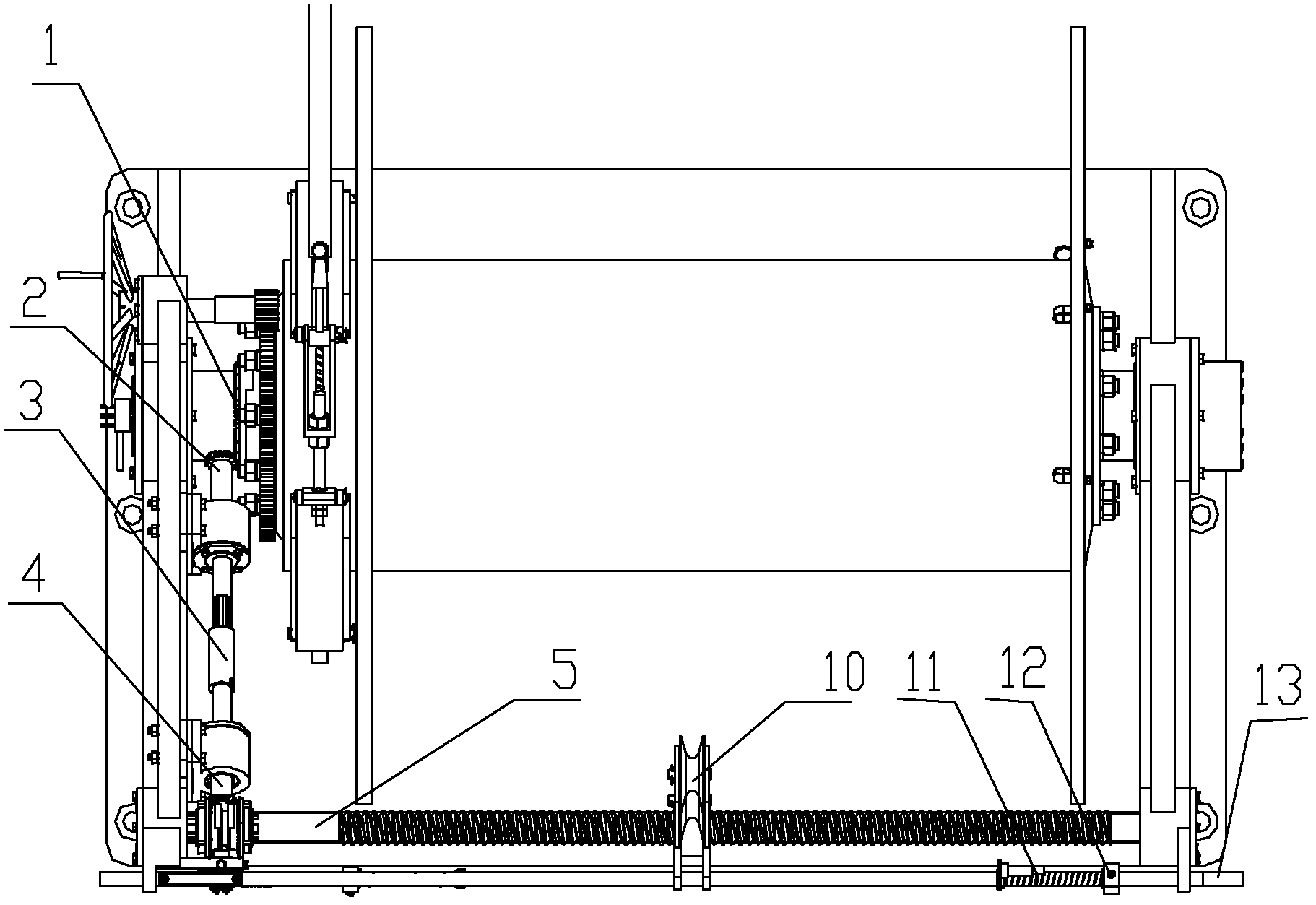

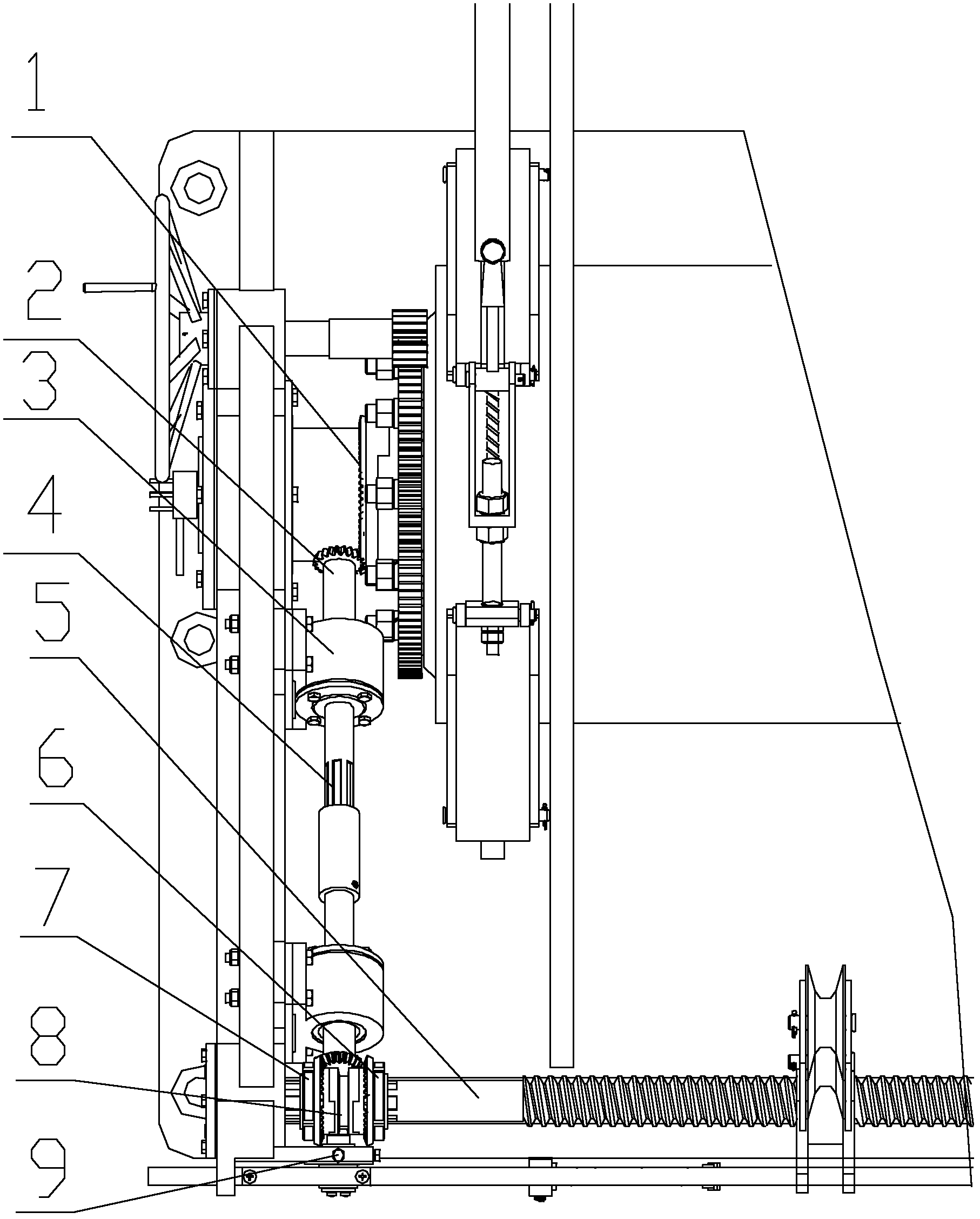

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0023] combine figure 1 and figure 2 , the first bevel gear 1 meshes with the first bevel gear shaft 2, the first bevel gear shaft 2 and the second bevel gear shaft 4 are connected through a coupling 3, the second bevel gear shaft 4 is connected with the second bevel gear 6 and the second bevel gear shaft The reversing bevel gear set composed of three bevel gears 7 (such as image 3 shown) meshes with one of the bevel gears. The rotation of the first bevel gear 1 will drive a bevel gear in the reversing bevel gear set to rotate, thereby driving the leading screw 5 to rotate. Simultaneously combine image 3 , the reversing bevel gear set consists of two identical oppositely mounted bevel gears.

[0024] The fairlead 10 is embedded with a nut, which can reciprocate along the axial direction of the leading screw under the drive of the leading screw 5; the pull ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com