Work piece installing and clamping device in ion beam polishing process and method thereof

A clamping device and ion beam technology, which is applied in the direction of grinding/polishing equipment, electrical components, manufacturing tools, etc., can solve the problems of curvature radius, damaged layer, eccentricity, roughness, and harsh surface PV value, etc., to achieve increased Large effective processing area, simple structure, and the effect of preventing structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

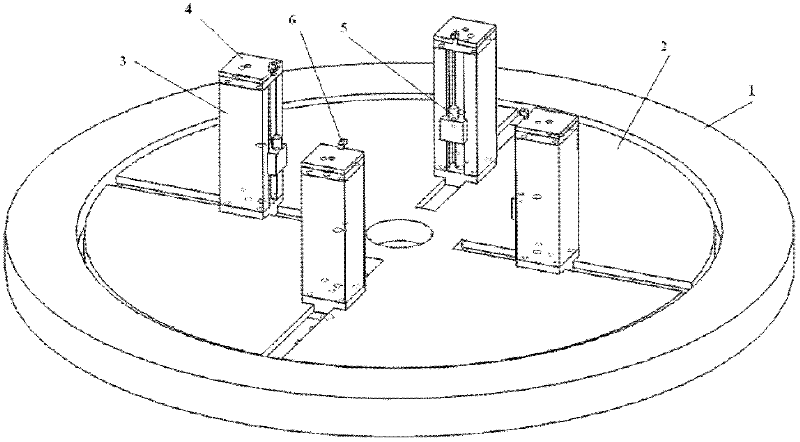

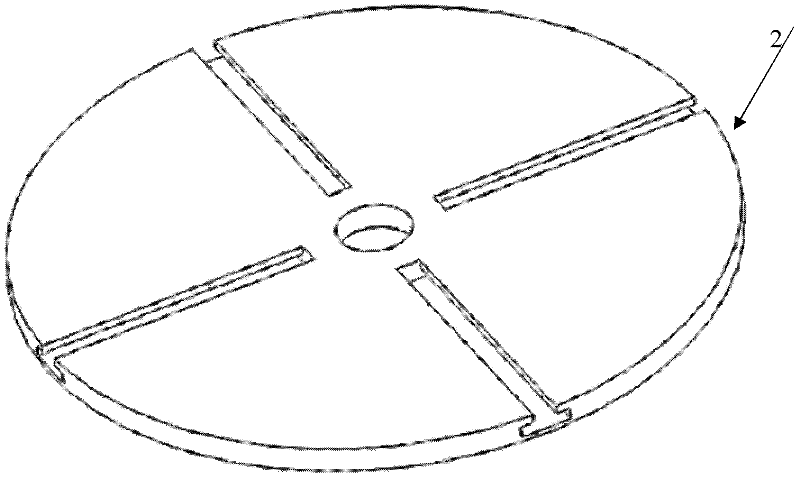

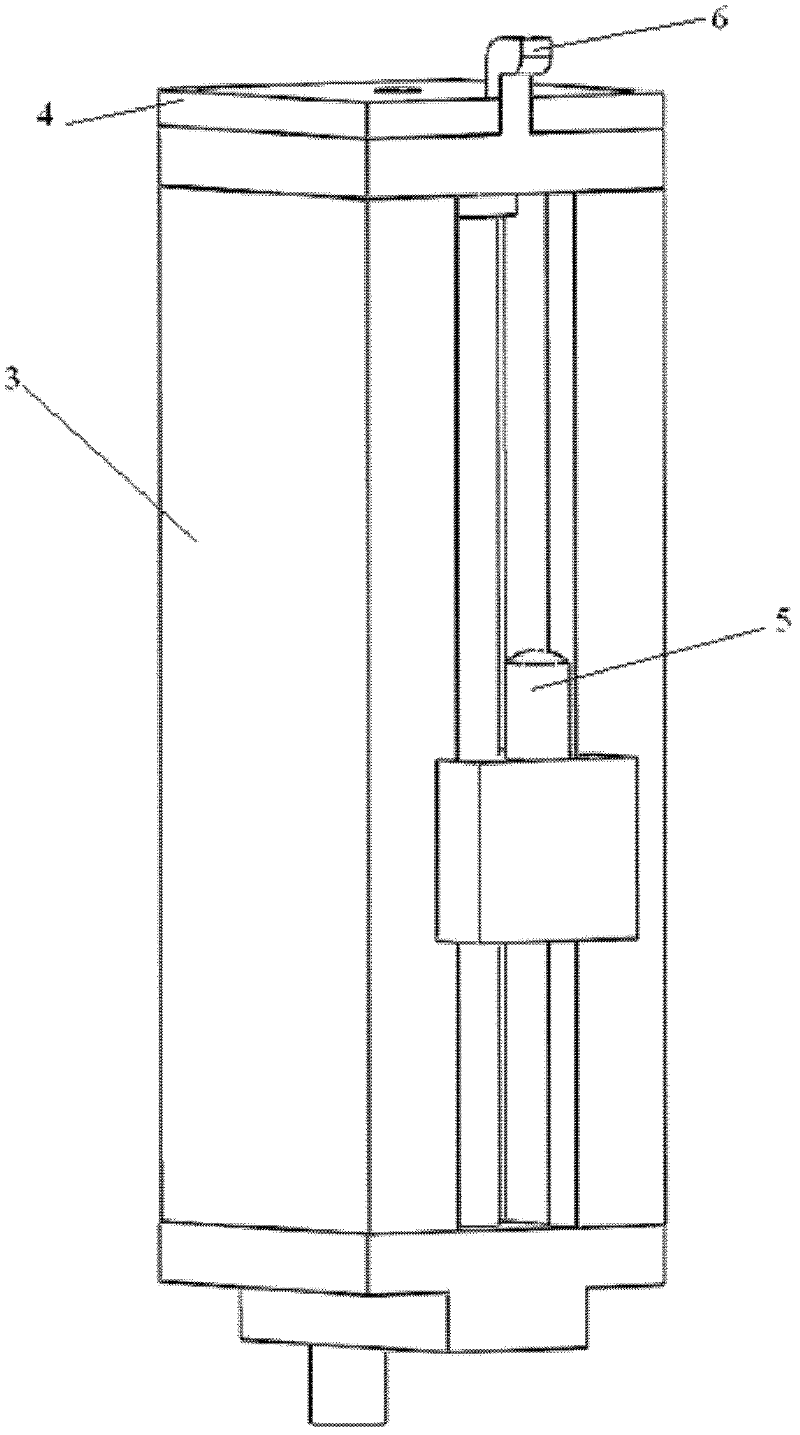

[0029] Example 1: Combining figure 1 The embodiment of the workpiece clamping device in the ion beam polishing process of the present invention includes a clamping main platform 1, a four-slot rotary table 2, a sliding fixed column 3, a ceramic cap piece 4, a lifting bracket structure 5 and a hook 6. The four-slot turntable 2 has four guide rail chutes orthogonally distributed in four directions on the upper end surface. The four-slot turntable 2 can be made of stainless steel, and the lower end surface is installed on the main card-loading platform 1 through a clamping structure and a ball connection, which can realize Free spins. Lifting bracket structure 5 and hook 6 are arranged on sliding fixed column 3, and hook 6 is installed on the upper end surface of sliding fixed column 3 by bolt, and the screw rod of lifting bracket structure 5 is installed in sliding fixed column 3 inside, and cylindrical support is installed on the screw rod, through The upper end surface of the...

Embodiment 2

[0032] Embodiment 2: Combination figure 1 Describe this embodiment, this embodiment is realized through the following steps:

[0033] Step S1: Determine a workpiece to be clamped and processed. The workpiece is assumed to be circular, with a diameter of Φ200mm and a thickness of 40mm. The upper surface is a convex spherical surface, and the lower surface is a concave spherical surface. According to the shape and size of the workpiece to be clamped, adjust the position of the movable fixed column 3 on the four-slot rotary table 2, so that the inner end surface of the sliding fixed column 3 is about 100mm away from the center of the four-slot rotary table 2, and fasten three of them. A sliding fixed column 3, the other remains loose and slidable;

[0034] Step S2: Adjust the distance between the lifting bracket structure 5 on the sliding fixing column 3 and the hook 6 to about 41 mm, move the loose sliding fixing column 3, and fix the workpiece to be loaded on the lifting brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com