Micro-water-column guiding laser micromachining device

A micro-machining and laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effects of small heat-affected zone, low cost, and small processing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

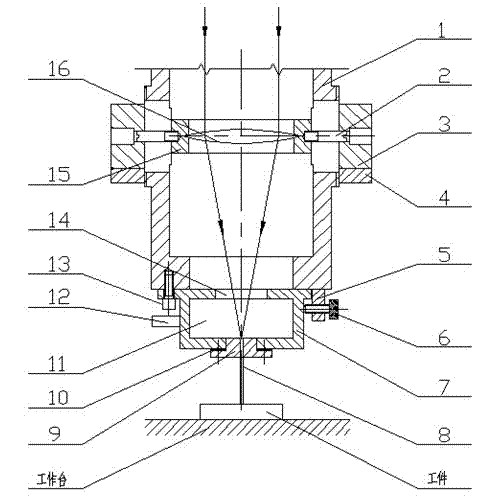

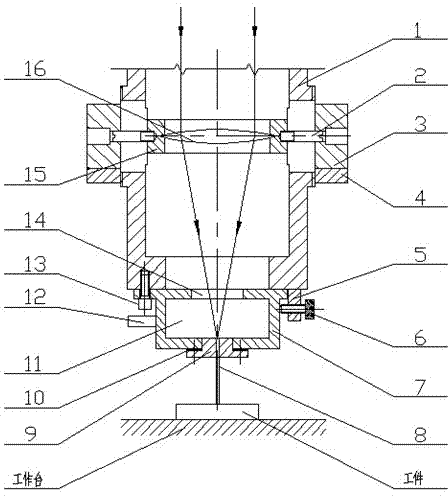

[0014] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

[0015] Such as figure 1 As shown, the micro-water column guided laser micromachining device includes a support sleeve 1, a water tank 7, a nozzle 9, an optical focus lens 16, etc., an optical focus lens 16 is horizontally installed in the support sleeve 1, and the optical focus lens 16 and the The nozzle hole center adjustment mechanism in the Z direction is connected. A water tank 7 is installed at the lower port of the support sleeve 1, and the water tank is connected to a pressurized water source through a water inlet joint 12. The center of the top of the water tank 7 is a quartz window 14, facing the center of the lower port of the support sleeve 1, the center of the bottom of the water tank 7 is provided with a nozzle 9, and the focal point of the optical focusing lens 16 just falls on the micropore center of the nozzle. The water tank 7 is also connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com