Sleeve mounting mechanism

A sleeve and collecting frame technology, applied in the field of upper sleeve mechanism, can solve the problems of no sleeve centering device, low quality of upper sleeve, high labor intensity, etc., achieve simple structure, easy maintenance and repair, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

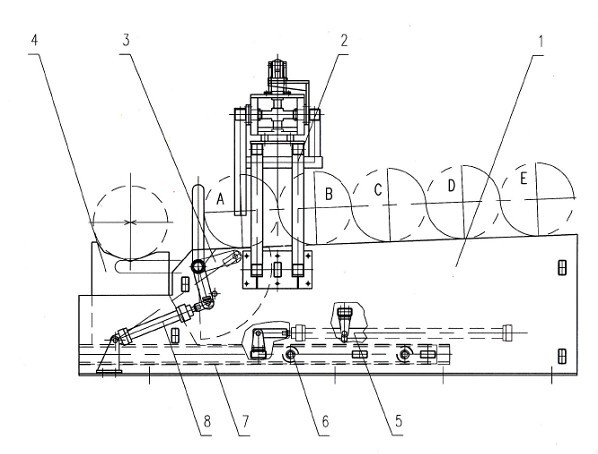

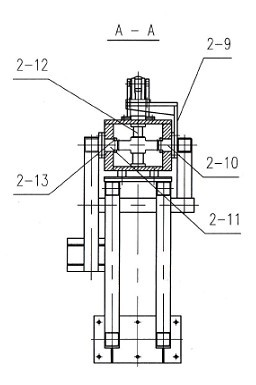

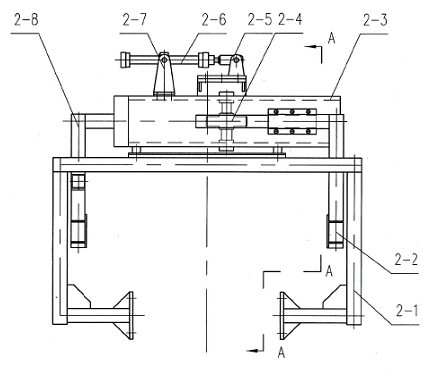

[0021] Such as figure 1 As shown, it is mainly composed of a sleeve collecting frame 1, a sleeve centering device 2, a fan-shaped shift fork 3, and a movable frame 4. Four major parts are formed. Socket collection rack 1 is welded by steel plate and used to store sleeves. The upper surface of sleeve collection rack 1 is an inclined plane, that is, the working surface for storing sleeves is an inclined plane; the inclination is the best inclination of 2°-3° It is 2.5 degrees.

[0022] In addition, sleeve collecting frame 1 is processed with installation sleeve centering device 2, shift fork 3, movable frame 4, movable frame drive oil cylinder 5 and the installation position of shift fork drive oil cylinder 8. The sleeve centering device 2 is fixedly installed on the sleeve collecting rack 1 with bolts. Sector shift fork 3 is installed on the sleeve collecting frame 1 by slide bearing 3-3 and slide bearing 3-7. Movable frame 4 is installed on the inboard of sleeve collecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com