Sand washing method and special device thereof

A special device, sand washing technology, applied in chemical instruments and methods, wet separation, solid separation, etc. The problem of poor sand experiment effect, etc., can achieve the effect of good sand washing effect, cost saving and space reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

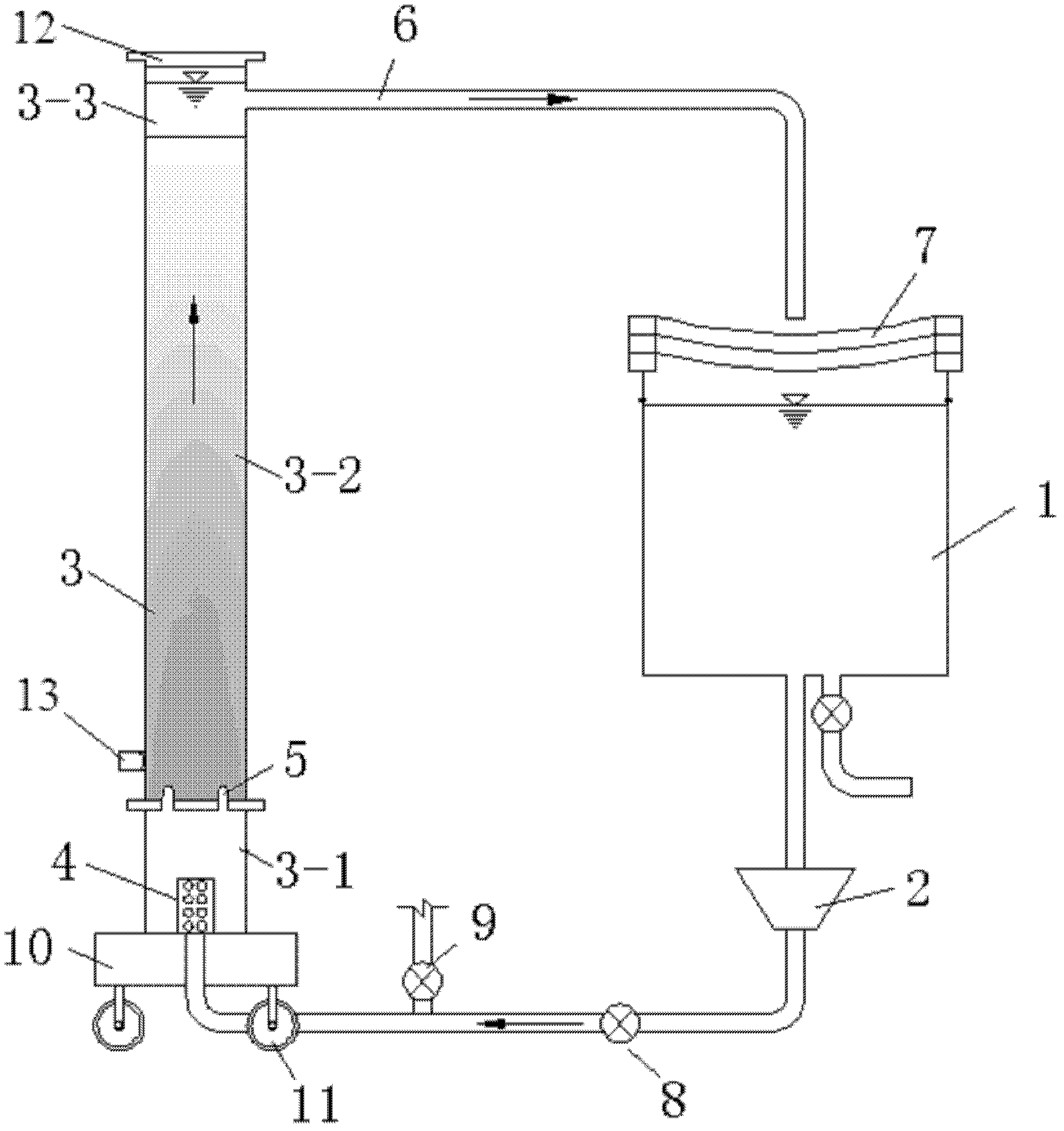

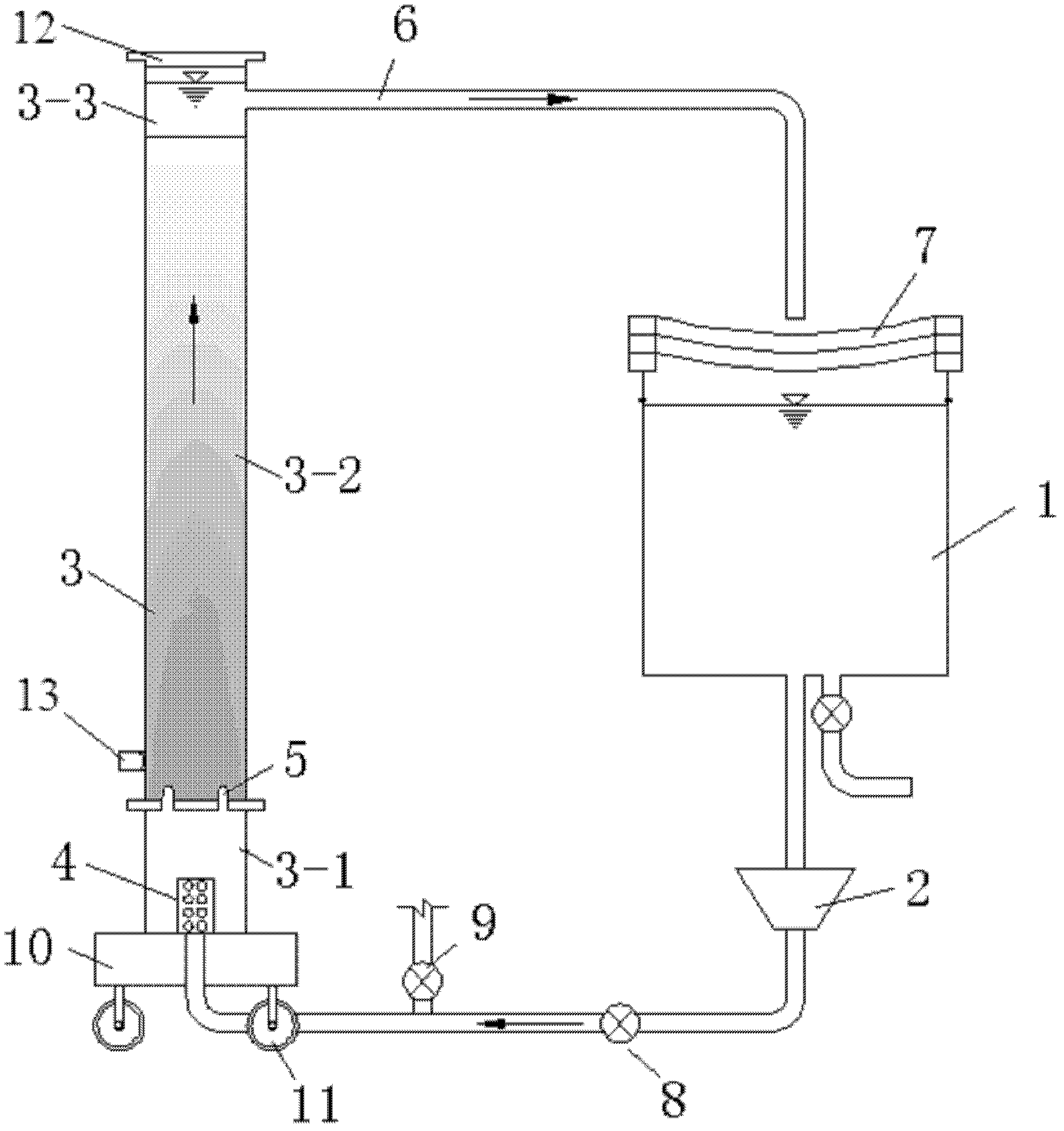

[0039] Embodiment 1: as figure 1As shown, the special device for washing sand of the present invention includes a water tank 1, a water pump 2 and an organic glass sand washing column 3, and the water tank 1 is connected with the water pump 2 and the organic glass sand washing column 3 successively through water pipes; The glass sand washing column 3 has a height of 160cm and an inner diameter of 19cm, and can clean 40Kg of sand each time; the plexiglass sand washing column is divided into the water inlet buffer zone 3-1, the sand column area 3-2 and the overflow zone according to the flow direction. Zone 3-3; the water inlet buffer zone 3-1 is distributed at the lowermost end of the plexiglass sand washing column 3, and a porous plexiglass tube buffer 4 is arranged at the water inlet; the water inlet buffer zone 3- 1 and the sand column area 3-2 are separated by four 0.5T / h cloth water caps 5 uniformly distributed in the ring, and when the water flow enters the plexiglass san...

Embodiment 2

[0040] Embodiment 2: The present invention adopts different cleaning methods for different silt to be cleaned to remove various impurities contained in the silt to be cleaned in a targeted manner. In this embodiment, the coarsely washed silt is taken as an example. Specifically include the following steps:

[0041] (1) Sand loading: put the sand to be cleaned into the sand washing column;

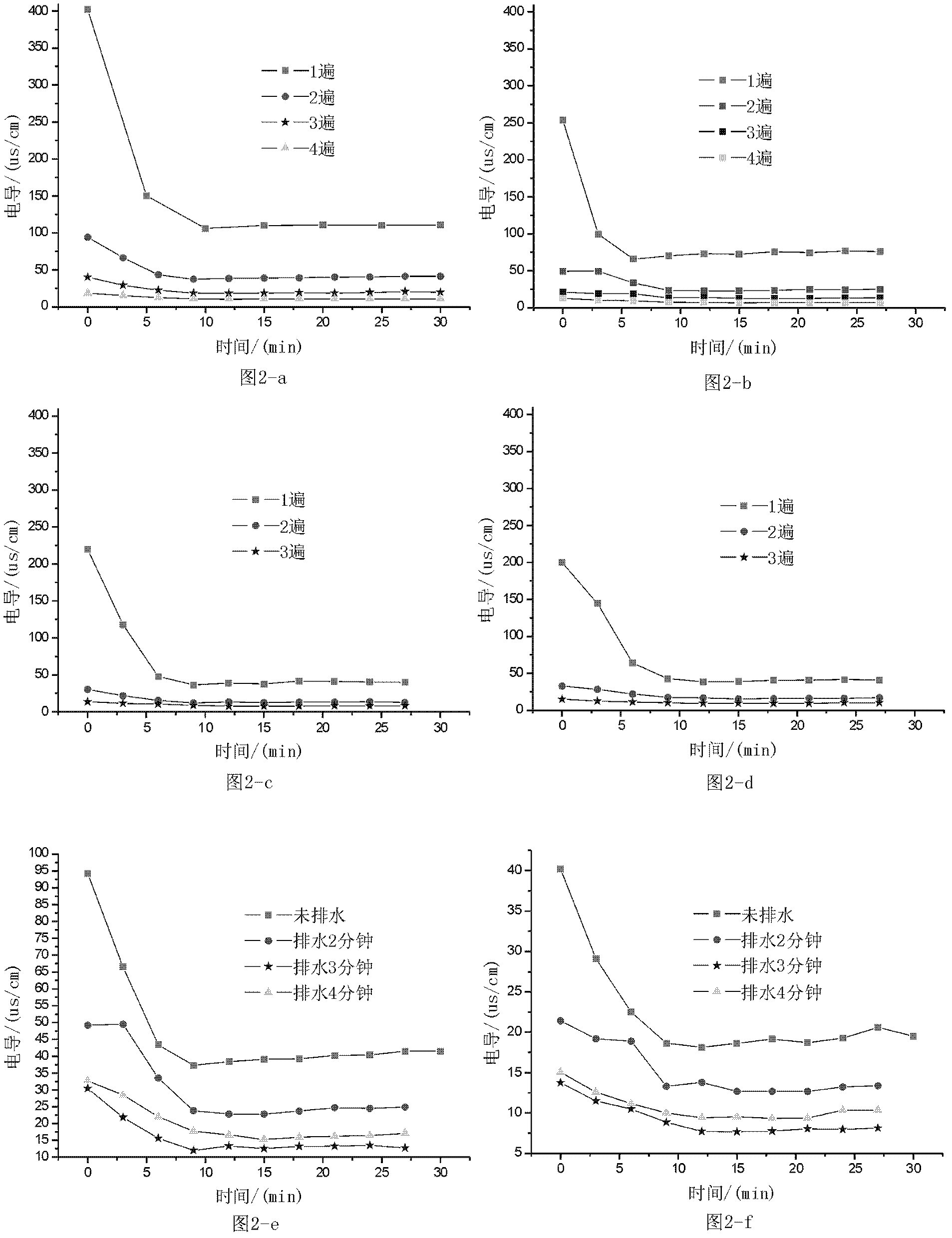

[0042] (2) (2-1) Washing: Use deionized water to circulate and wash 4 times from the lower end of the sand washing column to the upper end, and wash for 45 minutes each time to remove impurities and colloidal particles; because there are many initial impurities, in order to achieve optimal washing For the sand effect, drain outward for 6 minutes through overflow water management at the first start, and drain outward for 3 minutes through overflow water management at the beginning for the rest.

[0043] Add 100L of deionized water to the water tank each time. Considering that the concentra...

Embodiment 3

[0048] Embodiment 3: This embodiment takes the cleaning of the bed sand after the metal ion adsorption experiment as an example, and specifically includes the following steps:

[0049] (1) Sand loading: put the sand to be cleaned into the sand washing column;

[0050] (2) pickling: after carrying out the metal ion adsorption experiment, certain metal ions were adsorbed on the bed sand surface, in order to more effectively remove the metal adsorbed on the bed sand surface, soak for 2 days with an acid solution with a pH value of 3.5; Then wash it once with deionized water for about 1 hour; finally, wash it with an acid solution with a pH value of 3 for 12 hours to desorb the metal adsorbed on the sand surface and remove the metal in the sand;

[0051] (3) Cleaning with deionized water: after pickling, use deionized water to circulate and wash 4 times from the lower end of the sand washing column to the upper end, each time is about 45 minutes, and clean the desorbed metal ions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com