N-butane hydroisomerization catalyst, and preparation method and application thereof

A technology for hydroisomerization and catalyst, which is applied in the field of n-butane hydroisomerization catalyst, can solve the problems of catalyst activity and selectivity decline, and achieve the effect of improving diffusion limitation and changing pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

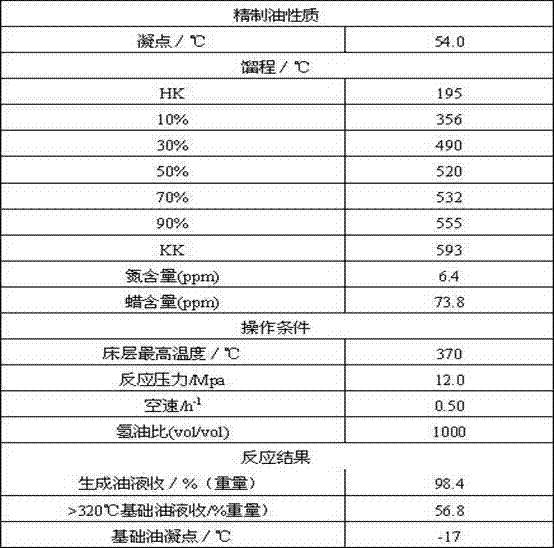

Image

Examples

Embodiment 1

[0033] Take 150 grams of commercially available NaY molecular sieves, impregnate with 80 ml of chlorinated mixed rare earth solution with a mass content of mixed rare earth metal oxides of 30% and 200 ml of deionized water, mix and stir at 25 ° C, and perform exchange modification for 2 hours, 110 °C After drying for 2 hours, pulverized, calcined at 500°C for 4 hours, then washed with 200ml deionized water at 25°C for 1 hour at room temperature, filtered, and the filter cake was dried at 120°C to obtain a modified Y molecular sieve, rare earth metal oxide The substance content is 12.4%, referred to as Y1 for standby. Rare earth chloride is a rare earth chloride industrial product used by Baotou Rare Earth Company for catalytic cracking, and the content of rare earth metal oxides is greater than 45%.

Embodiment 2

[0035] Take 150 grams of commercially available NaY molecular sieves, impregnate them with 80ml of chlorinated mixed rare earth solution with a mass content of mixed rare earth metal oxides of 35% and 200ml of deionized water, mix and stir at 25°C, and carry out exchange modification for 2 hours, at 110°C After drying at 500°C for 2 hours, crushing, and roasting at 500°C for 4 hours, washing with 200ml deionized water at room temperature, filtering for 1 hour, and drying the filter cake at 120°C to obtain a modified Y molecular sieve, wherein the rare earth metal oxide content 18.6%, referred to as Y2 reserve.

Embodiment 3

[0037] Take 150 grams of commercially available NaY molecular sieves, impregnate them with 80 ml of chlorinated mixed rare earth solution with a mass content of mixed rare earth metal oxides of 15% and 200 ml of deionized water, mix and stir at 25°C, and carry out exchange modification for 2 hours, at 110°C After drying at 500°C for 2 hours, crushing, and roasting at 500°C for 4 hours, washing with 200ml deionized water at room temperature, filtering for 1 hour, and drying the filter cake at 120°C to obtain a modified Y molecular sieve with a rare earth metal oxide content of 6.2%, referred to as Y3 reserve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com