Method for treating unsteady sulfur dioxide flue gas

A sulfur dioxide and treatment method technology, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of large energy, high processing cost, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

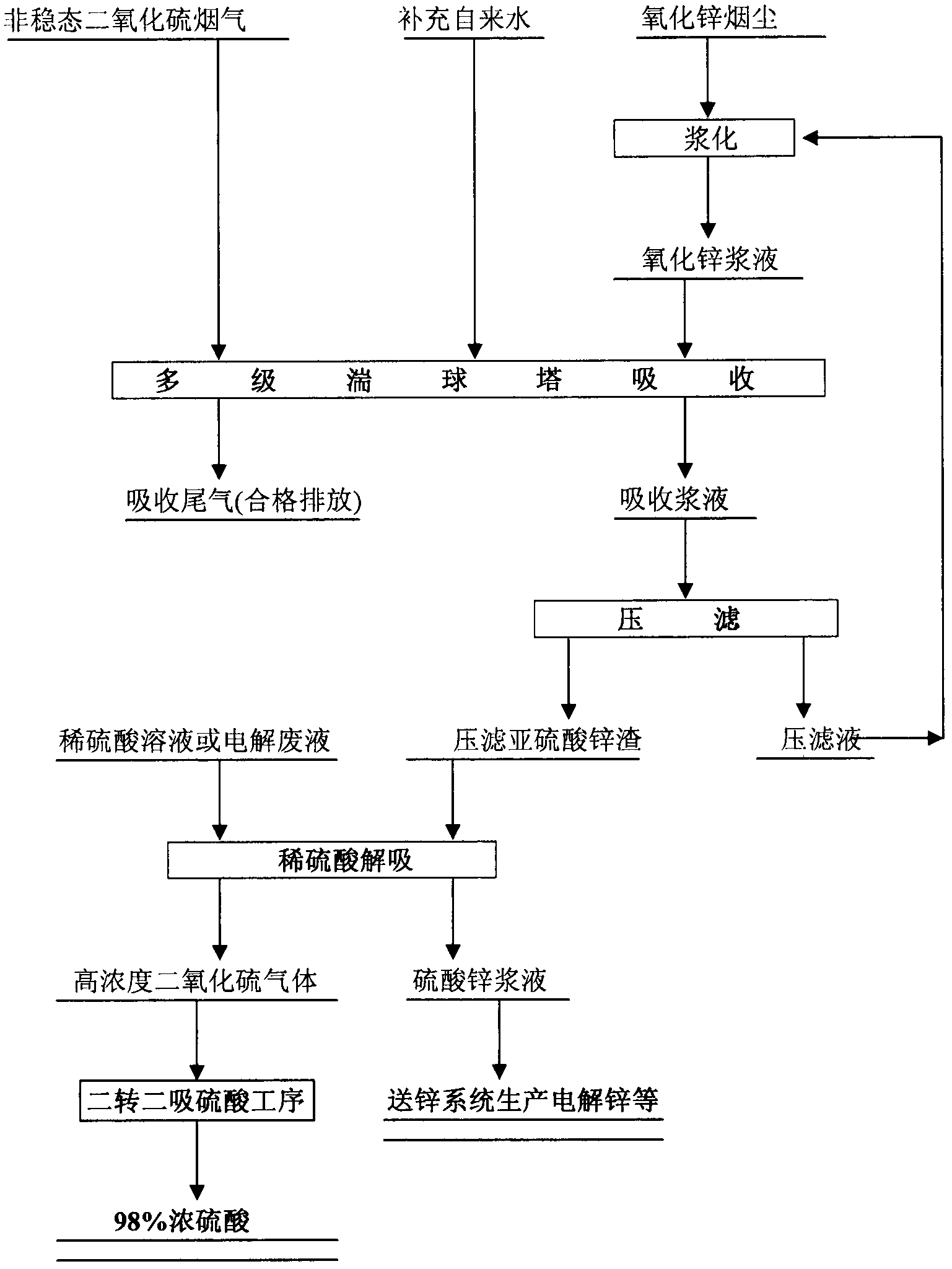

[0014] The present embodiment is the first example of the treatment method of unsteady state sulfur dioxide flue gas described in the present invention, comprises the following steps:

[0015] Zinc oxide containing 45% zinc is slurried at a liquid-solid ratio of 5:1, and pumped into a three-stage turbulent ball absorption tower with a delivery rate of 30 cubic meters per hour to absorb unsteady sulfur dioxide fumes flowing through the tower The flow rate of flue gas into the tower is 15,000-30,000 cubic meters per hour, the concentration of sulfur dioxide in the flue gas is 0.35-2.35%, and the absorption temperature is normal temperature. The sulfur dioxide content of the flue gas after absorption is 360 mg / standard cubic meter. The zinc sulfite slurry generated after absorption is separated from solid and liquid by a filter press, and the filter press solution is returned to zinc oxide slurry. Leach 20 cubic meters of electrolytic waste liquid with 150 g / L of acid, the leachi...

no. 2 example

[0017] This embodiment is the second example of the method for treating unsteady sulfur dioxide flue gas of the present invention, comprising the steps of:

[0018] Zinc oxide containing 60% zinc is slurried according to the liquid-solid ratio of 8:1, and then pumped into the three-stage turbulent ball absorption tower with a delivery flow rate of 40 cubic meters per hour to absorb the unsteady state of the flow through the tower. Sulfur dioxide flue gas, the flow rate of the flue gas into the tower is 25,000-35,000 cubic meters per hour, the concentration of sulfur dioxide in the flue gas is 1.58-3.82%, the absorption is carried out at room temperature, and the sulfur dioxide content of the absorbed flue gas is 450 mg / standard cubic meter, which is directly discharged , the zinc sulfite slurry generated after absorption is separated from solid and liquid with a filter press, and the filter press solution is returned to zinc oxide slurry, and the filter press residue is 12 tons...

no. 3 example

[0020] The present embodiment is the third example of the treatment method of unsteady state sulfur dioxide flue gas described in the present invention, comprises the following steps:

[0021] Zinc oxide containing 80% zinc is slurried according to the liquid-solid ratio of 10:1, and then pumped into the three-stage turbulent ball absorption tower with a delivery flow rate of 50 cubic meters per hour to absorb the unsteady state of the flow through the tower. Sulfur dioxide flue gas, the flow rate of the flue gas into the tower is 20,000-50,000 cubic meters per hour, the concentration of sulfur dioxide in the flue gas is 1.08-5.82%, and the sulfur dioxide content of the absorbed flue gas is less than 652 mg / standard cubic meter, which is directly discharged and generated after absorption The zinc sulfite slurry is separated by a filter press, and the filter solution is returned to the zinc oxide slurry, and the filter residue is 15 tons, and it is leached with 16 cubic meters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com