Roast chicken curing material and preparation method thereof

A technology for marinating and roasting chicken, which is applied in the field of roasting chicken marinating and its preparation, can solve the problems of single taste, high salt content, low fresh powder content, etc., and achieves stable product quality, crispy taste on the outside and crispy inside. Tender, golden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

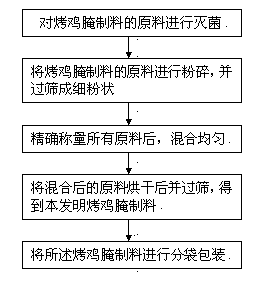

[0036] Grilled chicken marinade of the present invention can adopt following preparation method:

[0037] Step 1: Sterilize the raw materials of the grilled chicken marinade of the present invention. In the present invention, because the spices are easy to exceed the standard of microorganisms, the spices are sterilized before the raw materials are mixed, and hot air drying, far-infrared ray sterilization, etc. can be used.

[0038] Step 2: All raw materials are crushed and sieved into fine powder; all raw materials must meet national standards. Raw materials should be pulverized and passed through a 100-mesh sieve to form a fine powder, which can improve the fluidity of raw materials and facilitate uniform mixing. In the present invention, the raw material to be pulverized is determined according to the particle size of the raw material. In the present invention, the raw materials of spices are pulverized and passed through a 100-mesh sieve into fine powder.

[0039] Step ...

Embodiment 1

[0044] In the present embodiment, the mass fractions of raw materials for preparing the grilled chicken marinade of the present invention are respectively: 20% of salt, 20% of sugar, 7% of monosodium glutamate, 3% of chicken essence, 2% of chili powder, 1% of garlic powder, 1% of onion powder, Ginger powder 1%, fresh chicken powder 3%, yeast powder 2%, paprika 0.05%, turmeric 0.05%, silicon dioxide 0.5%, modified starch 1%, maltodextrin 38.4%.

[0045] The preparation method comprises the following steps:

[0046] (1) Sterilize spices such as chili powder, garlic powder, onion powder and ginger powder in a hot air dryer at a temperature of 100°C and a wind speed of 0.3m / s for 4 hours.

[0047] (2) Grind the dried and sterilized spices, and pass through a 100-mesh sieve into powder.

[0048] (3) Weigh each raw material separately according to the mass fraction of the above-mentioned raw materials, and the total amount is 10 kg. Mix the raw materials according to the equal dil...

Embodiment 2

[0053] In the present embodiment, the mass fractions of raw materials for preparing roasted chicken marinade of the present invention are respectively: 25% of salt, 35% of sugar, 7% of monosodium glutamate, 3% of chicken essence, 6% of chili powder, 2% of garlic powder, 2% of onion powder, Ginger powder 2%, fresh chicken powder 3%, yeast powder 2%, paprika 0.1%, turmeric 0.1%, silicon dioxide 0.5%, modified starch 1%, maltodextrin 11.3%.

[0054] The preparation method comprises the following steps:

[0055] (1) Sterilize spices such as chili powder, garlic powder, onion powder and ginger powder in a hot air dryer at a temperature of 100°C and a wind speed of 0.3m / s for 4 hours.

[0056] (2) Grind the dried and sterilized spices, and pass through a 100-mesh sieve into powder.

[0057] (3) Weighing and mixing Weigh each raw material separately according to the mass fraction of the above-mentioned raw materials, and the total amount is 10 kg. The raw materials are mixed accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com