Simulated experiment method of overheat faults of contact surface in sulfur hexafluoride gas insulation equipment

A technology for sulfur hexafluoride gas and fault simulation, which is applied to instruments, measuring devices, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

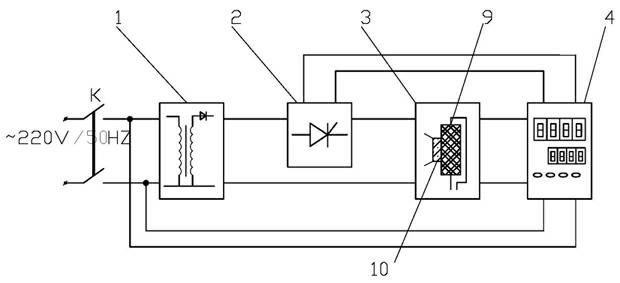

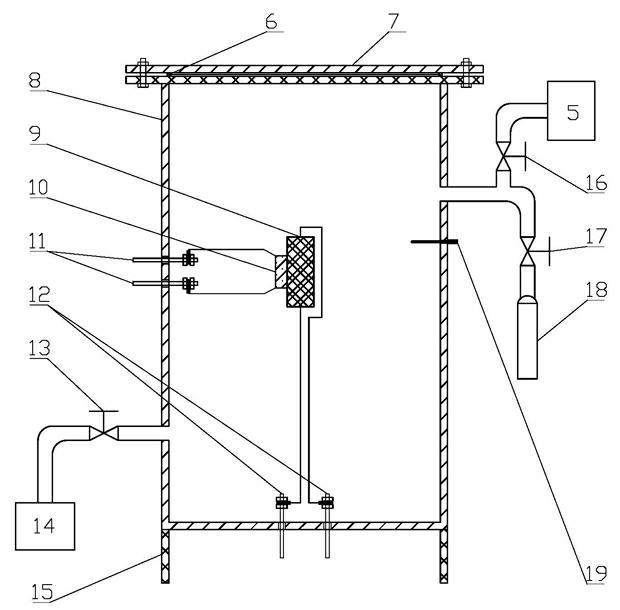

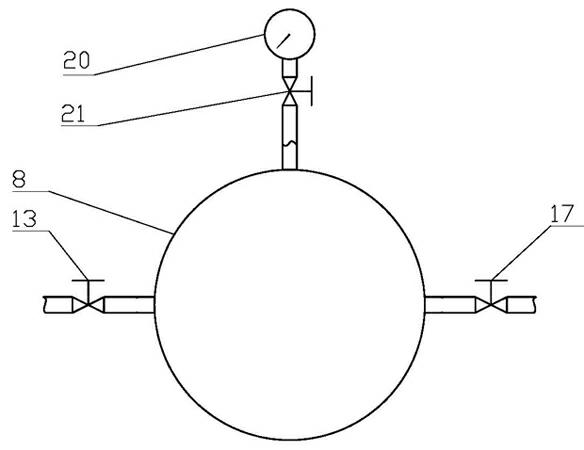

Method used

Image

Examples

Embodiment 1

[0038] a SF 6 The simulated experimental method of the overheating fault of the contact surface of gas-insulated electrical equipment, using the "SF 6 Simulation device for overheating faults at the contact surfaces of gas-insulated electrical equipment", for SF 6 The specific steps for the simulation experiment and analysis of overheating faults of gas-insulated electrical equipment are as follows:

[0039] Experiment preparation

[0040] Place the heating element and check the sealing performance of the overheating fault simulation component of the device

[0041]First open the seal 6 of the cylinder body 8 of the overheating fault simulation component 3 of the device, and connect the two wiring poles of the heating element 9 made of aluminum to the two temperature sensors at the bottom of the device through hard insulated copper wires respectively. One end of the terminal 11 located in the cylinder body 8 is connected, and the heating element 9 is supported on the ax...

Embodiment 2

[0053] a SF 6 The simulation experiment method of the overheating fault of the contact surface of gas-insulated electrical equipment is the same as that of Example 1, wherein: the first — Put into the heating element 9 of electrolytic copper material in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com