Method for analyzing N2O, CO, CH4 and CO2 in atmosphere with one injection by gas chromatography

A gas chromatography, CH4 technology, applied in the direction of analysis of materials, material separation, measurement devices, etc., can solve the problems of prolonging the sample measurement cycle and large data accuracy errors, shortening the sample measurement cycle, reducing the data accuracy error, data accuracy and so on. The effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

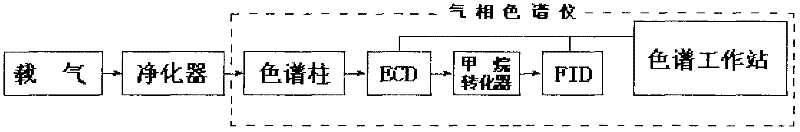

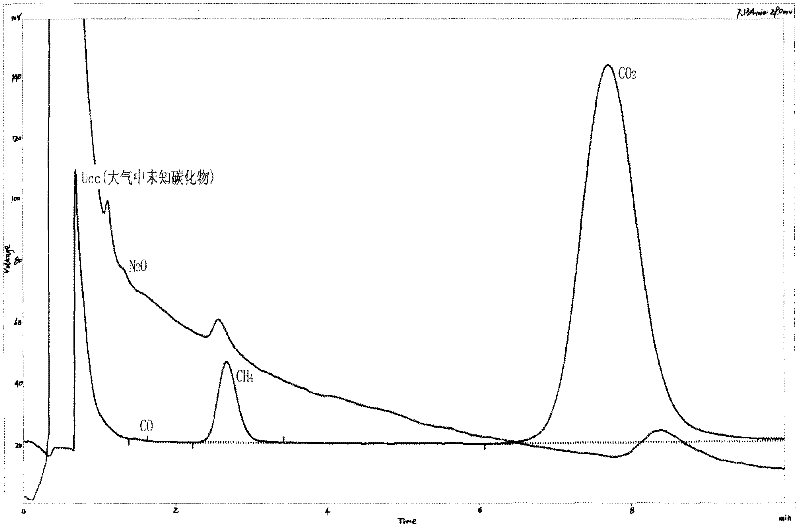

[0025] Example 1 Gas Chromatography One-shot Analysis of N in the Atmosphere 2 O, CO, CH 4 , CO 2 , first reduce the purity to less than 10 -5 % carrier gas - He passes through the purifier at an output pressure of 0.20Mpa, so that the purity of the purified carrier gas is less than 10 -6 %; then pass the purified carrier gas into the chromatographic column in the gas chromatograph where the sample to be tested has been placed at a flow rate of 25ml / min at a temperature of 10°C, and after adsorption and desorption at a temperature of 20°C , N in the sample to be tested 2 O, CO, CH 4 , CO 2 Enter the electron capture detector (ECD), methane reformer and hydrogen flame ionization detector (FID) in sequence, and detect at a temperature of 90 ° C; finally the electron capture detector (ECD) and hydrogen flame ionization detector (FID ) The obtained data are simultaneously input to the chromatographic workstation in the gas chromatograph, and the analysis result chromatogram ...

Embodiment 2

[0028] Example 2 Gas Chromatography One-shot Analysis of N in the Atmosphere 2 O, CO, CH 4 , CO 2 , first reduce the purity to less than 10 -5 % carrier gas—Ne passes through the purifier at an output pressure of 0.60Mpa, so that the purity of the purified carrier gas is less than 10 -7 %; then pass the purified carrier gas into the chromatographic column of the gas chromatograph where the sample to be tested has been placed at a temperature of 40°C at a flow rate of 195ml / min, and after adsorption and desorption at a temperature of 250°C , N in the sample to be tested 2 O, CO, CH 4 , CO 2 Enter the ECD, the methane converter and the FID in sequence, and perform detection at a temperature of 350°C; finally, the data obtained by the ECD and the FID are simultaneously input to the chromatographic workstation in the gas chromatograph, and the chromatogram of the analysis result can be obtained.

[0029] Among them: the chromatographic column refers to a stainless steel tube...

Embodiment 3

[0031] Example 3 Gas Chromatography One-shot Analysis of N in the Atmosphere 2 O, CO, CH 4 , CO 2 , first reduce the purity to less than 10 -5 % of carrier gas——Ar passes through the purifier at an output pressure of 0.40Mpa, so that the purity of the purified carrier gas is less than 10 -6 %; then pass the purified carrier gas into the chromatographic column of the gas chromatograph where the sample to be tested has been placed at a temperature of 15°C at a flow rate of 110ml / min, and after adsorption and desorption at a temperature of 150°C , N in the sample to be tested 2 O, CO, CH 4 , CO 2 Enter the ECD, methane converter and FID in sequence, and perform detection at a temperature of 220°C; finally, the data obtained by the ECD and FID are simultaneously input to the chromatographic workstation in the gas chromatograph, and the chromatogram of the analysis result can be obtained.

[0032] Among them: the chromatographic column refers to a stainless steel tube with an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com