Bending machine workbench precision bidirectional mechanical deflection compensation device and fabrication method thereof

A compensation device and worktable technology, applied in the field of bending machines, can solve the problems of accumulated errors, poor straightness of workpieces, and poor consistency of bending angles of workpieces in the entire length, so as to achieve convenient operation, improve bending accuracy, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

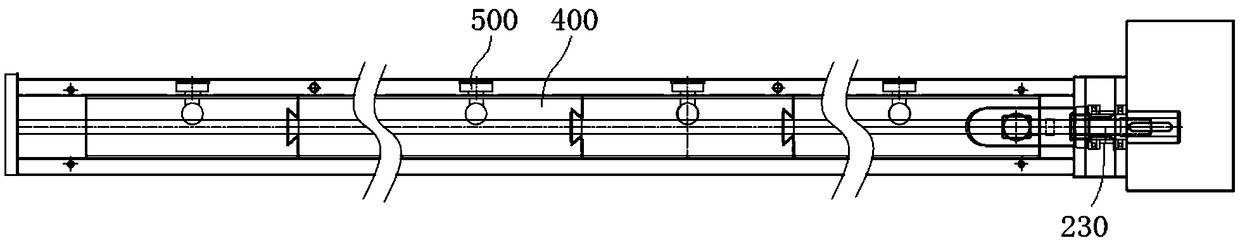

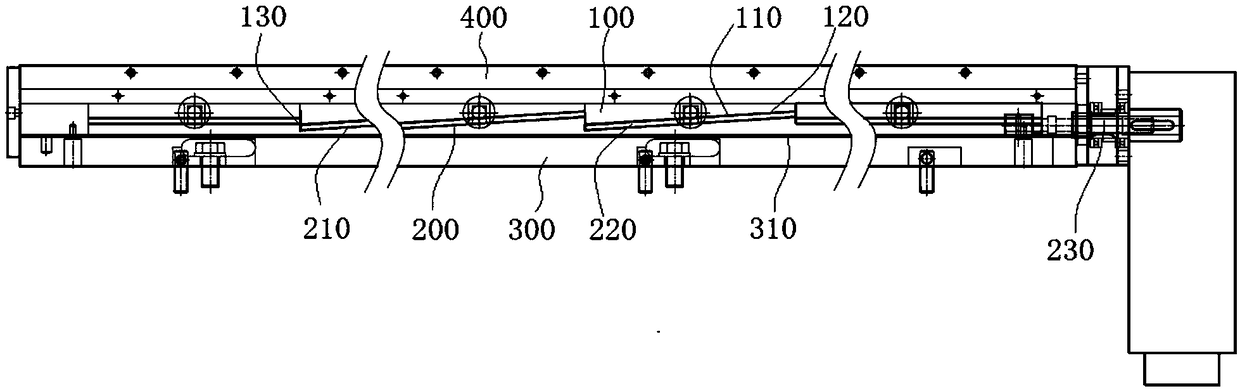

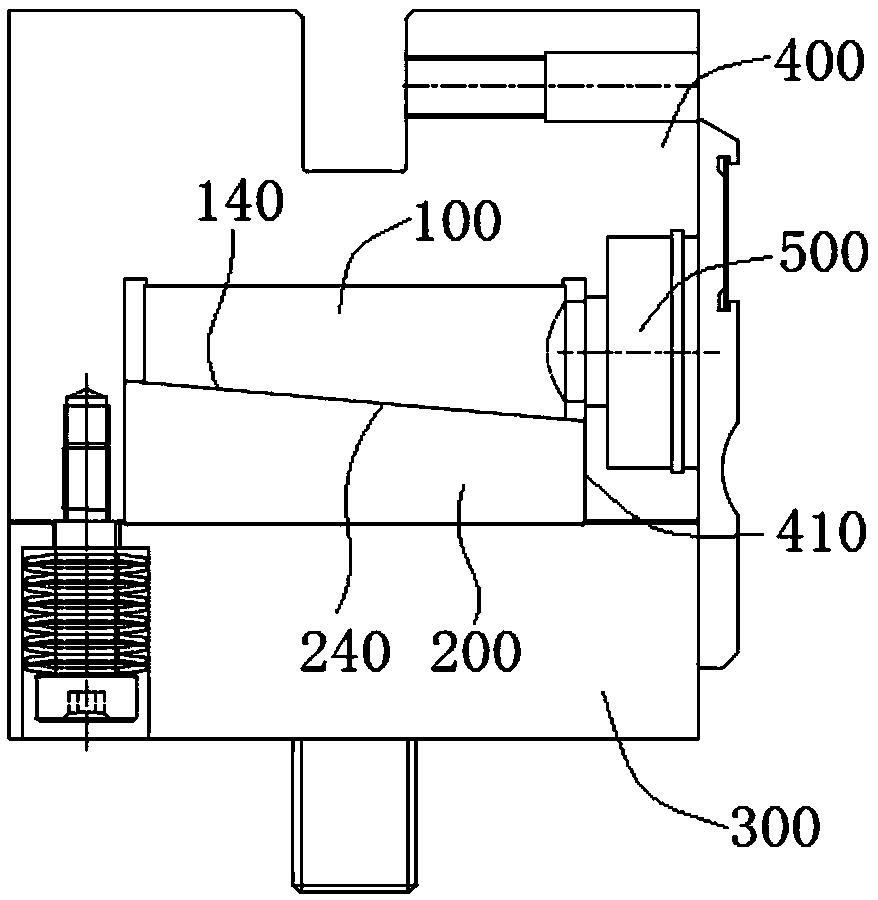

[0047] Please refer to Figure 1 to Figure 3 , The precision two-way mechanical deflection compensation device of the worktable of the bending machine, including the base 300, the cover 400, the upper inclined plate 100, the lower inclined plate 200 and the adjustment mechanism, the upper inclined plate 100 and the lower inclined plate 200 are made of the same material, and are made of high The strength steel is processed.

[0048] The upper inclined plate 100 is divided into several sections, the lower surface 110 is provided with a first longitudinal inclined surface 120 facing the longitudinal direction, the lower inclined plate 200 is an integral structure, and the upper surface 210 of the lower inclined plate 200 is provided with a first longitudinal inclined surface 120 to cooperate with The second longitudinal slope 220, the slopes of the first longitudinal slope 120 and the second longitudinal slope 220 are reduced from a large slope Kj to a small slope Ki from the middle...

Embodiment 2

[0054] The manufacturing method of the precision bidirectional mechanical deflection compensation device for the worktable of the bending machine of the present invention includes the steps:

[0055] S101. Select two plates of the same high-strength steel material, 45# carbon steel chemical composition: C content is 0.50%; Si content is 0.2%; Mn content is 0.5%; Cr content is less than or equal to 0.25%; Ni content is less than or equal to 0.30%; Cu The content is less than or equal to 0.25%, and the rest is Fe.

[0056] S102. On the CNC machine tool, determine one end of the upper inclined plate 100 as the starting point of machining, and use the vertical surface to machine the first inclined surface 120 of the upper inclined plate 100, where the amount of cutting per time L1=[W(C) / W(Si )]*0.1=0.5 / 0.2*0.1=0.25mm; cutting speed V1=[(W(C)+W(Mn)) / W(Si)]*500=(0.5+0.5) / 0.2*500= 2500mm / min, W(C), W(Mn), W(Si) are all expressed as weight percentages. The slope K of the first longitudina...

Embodiment 3

[0061] The manufacturing method of the precision bidirectional mechanical deflection compensation device for the worktable of the bending machine of the present invention includes the steps:

[0062] S101. Select two plates of the same high-strength steel material, 60# carbon steel chemical composition: C content is 0.6%; Si content is 0.2%; Mn content is 0.6%; Cr content is ≤0.25%; Ni content is ≤0.30%; Cu Content≤0.25%, the rest is Fe;

[0063] S102. On the CNC machine tool, determine one end of the upper inclined plate 100 as the starting point of machining, and use the vertical surface to machine the first longitudinal inclined surface 120 of the upper inclined plate 100, where the amount of feed each time L1=[W(C) / W( Si)]*0.1=0.6 / 0.2*0.1=0.3mm; knife speed V1=[(W(C)+W(Mn)) / W(Si)]*500=(0.6+0.6) / 0.2*500 =3000mm / min, W(C), W(Mn), W(Si) all represent weight percentages, the slope K of the first longitudinal inclined surface 120 determines the value of different segments according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com