High-precision metal pipe bending system and method thereof

A technology of metal pipe fittings and processing systems, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems such as low bending precision, and achieve high production efficiency, stable production, and high bending precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

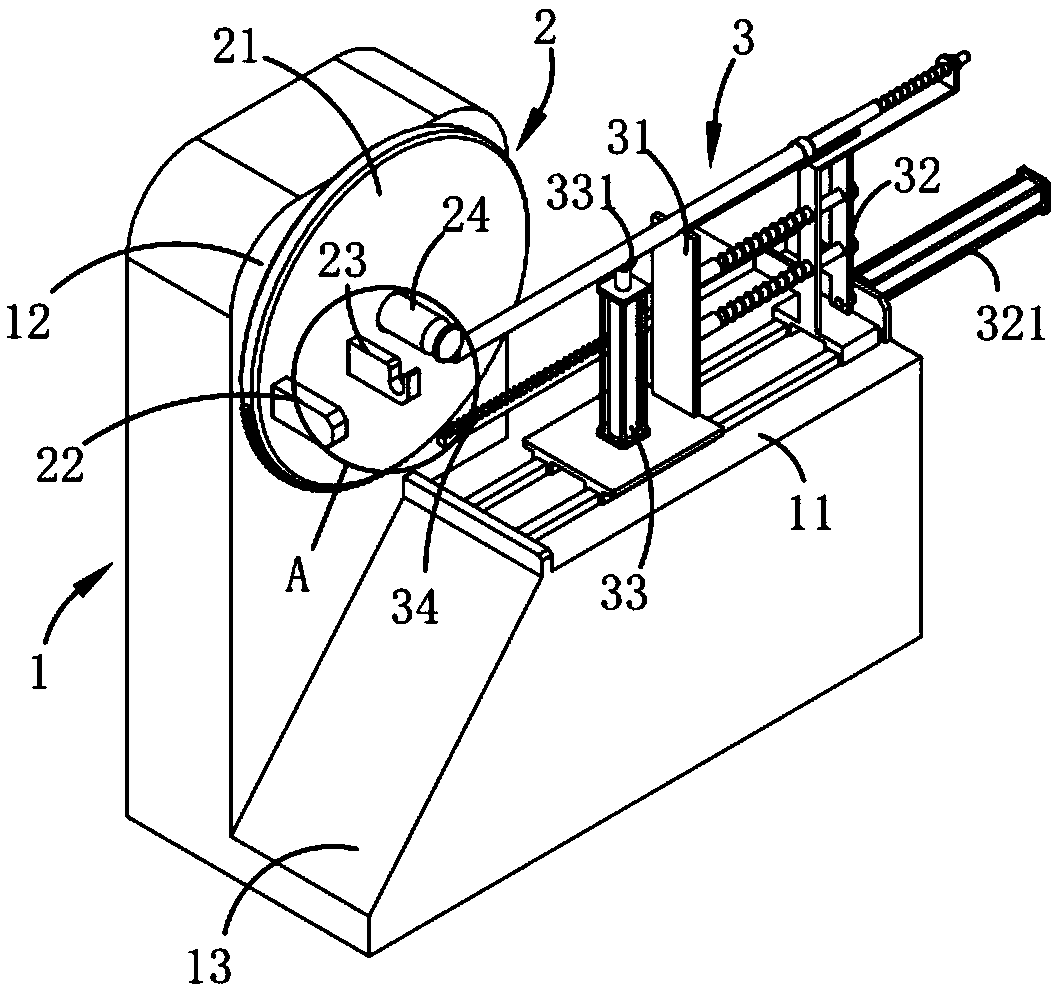

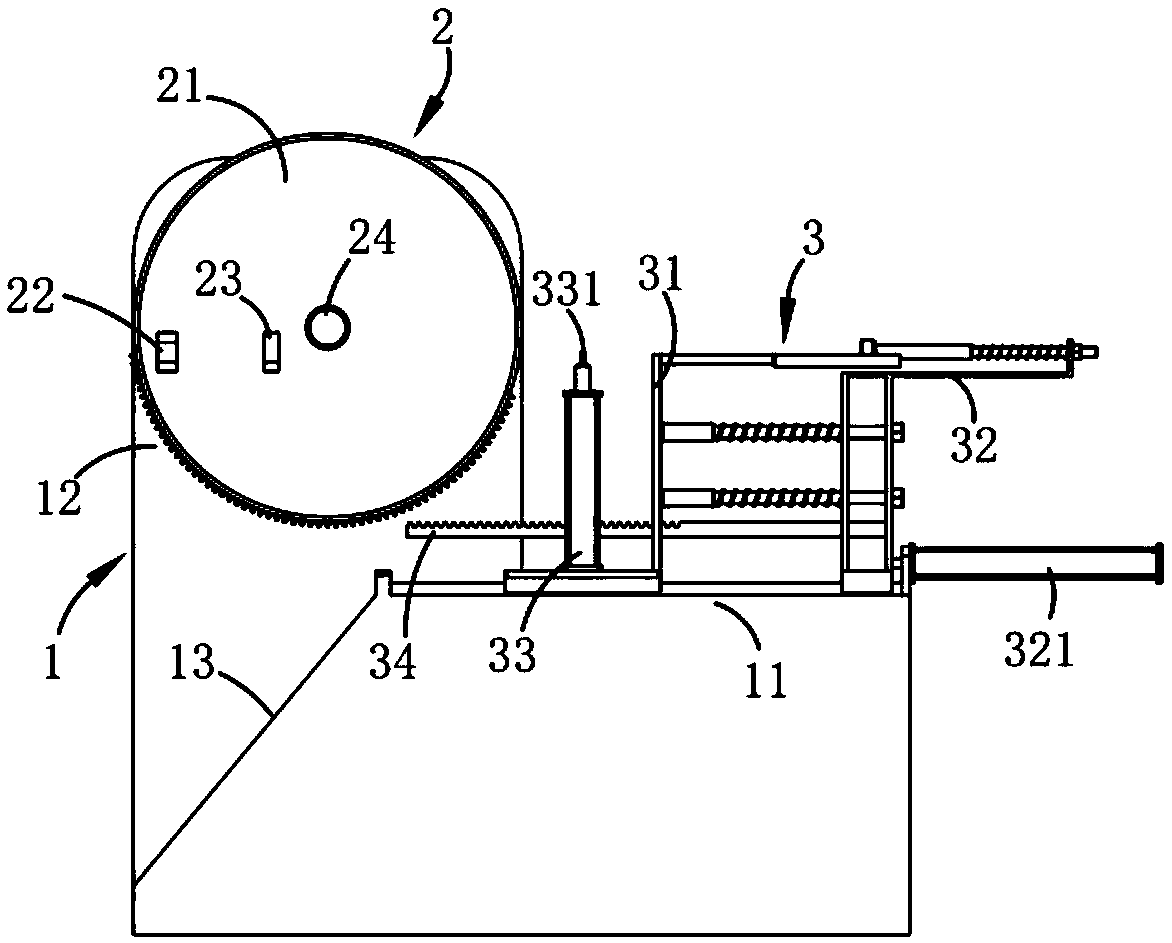

[0041] Such as figure 1 , 2 , 3, 4, 5 and 6, a high-precision bending processing system for metal pipe fittings is characterized in that it includes:

[0042]Frame 1, said frame 1 comprising a horizontal mounting platform 11, a vertical mounting platform 12 and a blanking slide 13 arranged at one end of said horizontal mounting platform 11 and below said vertical mounting platform 12;

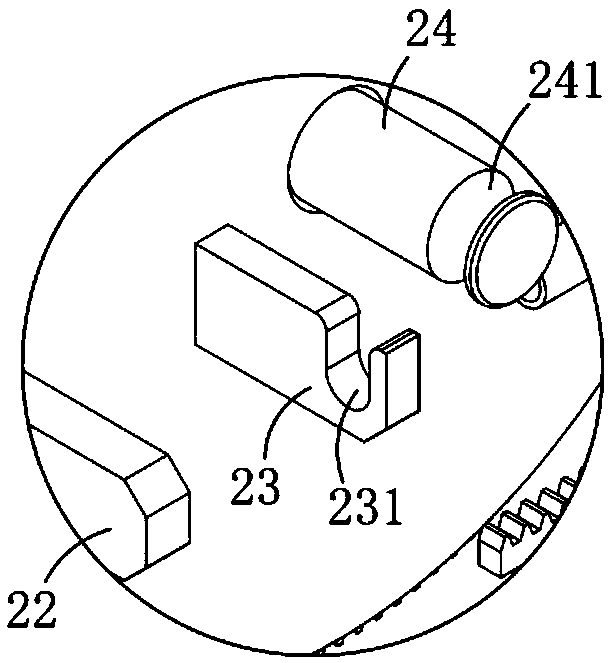

[0043] Positioning mechanism 2, described positioning mechanism 2 is arranged on described vertical mounting platform 12, and it comprises turn...

Embodiment 2

[0050] Among them such as Figure 5 and 7 As shown, the same or corresponding components as in Embodiment 2 use the corresponding reference numerals as in Embodiment 1. For the sake of simplicity, only the differences between Embodiment 2 and Embodiment 2 are described below; the differences between Embodiment 3 and Embodiment 2 The location component 31 also includes a connecting plate 314 connecting the slide table 311 and the placing groove 312, a transmission part 315 arranged on the connecting plate 314 and connected with the support seat 322, the transmission The part 315 includes at least one guide rod 3151 fixedly arranged on the connecting plate 314 along the horizontal direction and a spring 3152 sleeved on the guide rod 3151. The placement assembly 31 is driven to move by the transmission part 315. In this embodiment, there are two transmission parts 315 arranged side by side in the vertical direction. The other end of the guide rod 3151 is limited by a nut, and it...

Embodiment 3

[0055] According to the manual attached Figure 9 A high-precision bending processing method for metal pipe fittings in this embodiment is described.

[0056] A high-precision bending processing method for metal pipe fittings, comprising the following steps:

[0057] (a) For the feeding part, manually place the steel pipe to be bent in the placement groove 312 on the conveying mechanism 3 along its axial direction;

[0058] (b) the pushing part, after the step (a), the push rod 3231 arranged on the support base 322 is driven to move in a reciprocating manner by the driving part 321 on the pushing assembly 32, and the to-be-be placed on the placement groove 312 The bent steel pipe is pushed into the positioning groove 221 on the turntable 21;

[0059] (c) Preliminary bending. After the step (b), the driving part 321 continues to push the support seat 322 to move, and the transmission assembly 34 drives the turntable 21 to rotate in a rack and pinion transmission mode, and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com