Mixed-potential nitrogen dioxide sensor based on porous YSZ (yttria stabilization zirconia) substrate and preparation method for sensor

A mixed potential type, nitrogen dioxide technology, applied in instruments, scientific instruments, material analysis through electromagnetic means, etc., can solve the problem that the sensitivity cannot meet the practical requirements, and achieve the promotion of practical application, cost reduction and sensitivity improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

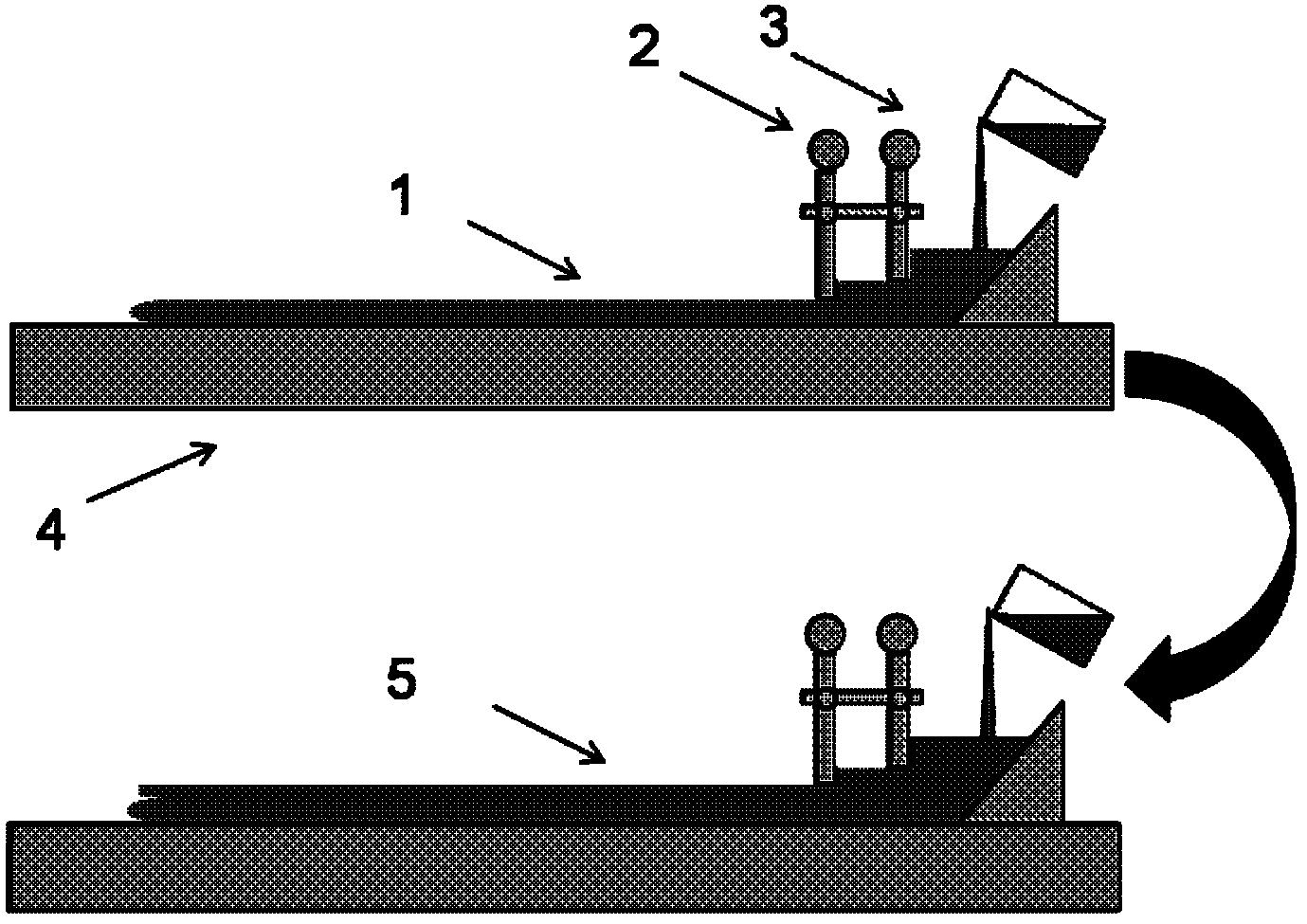

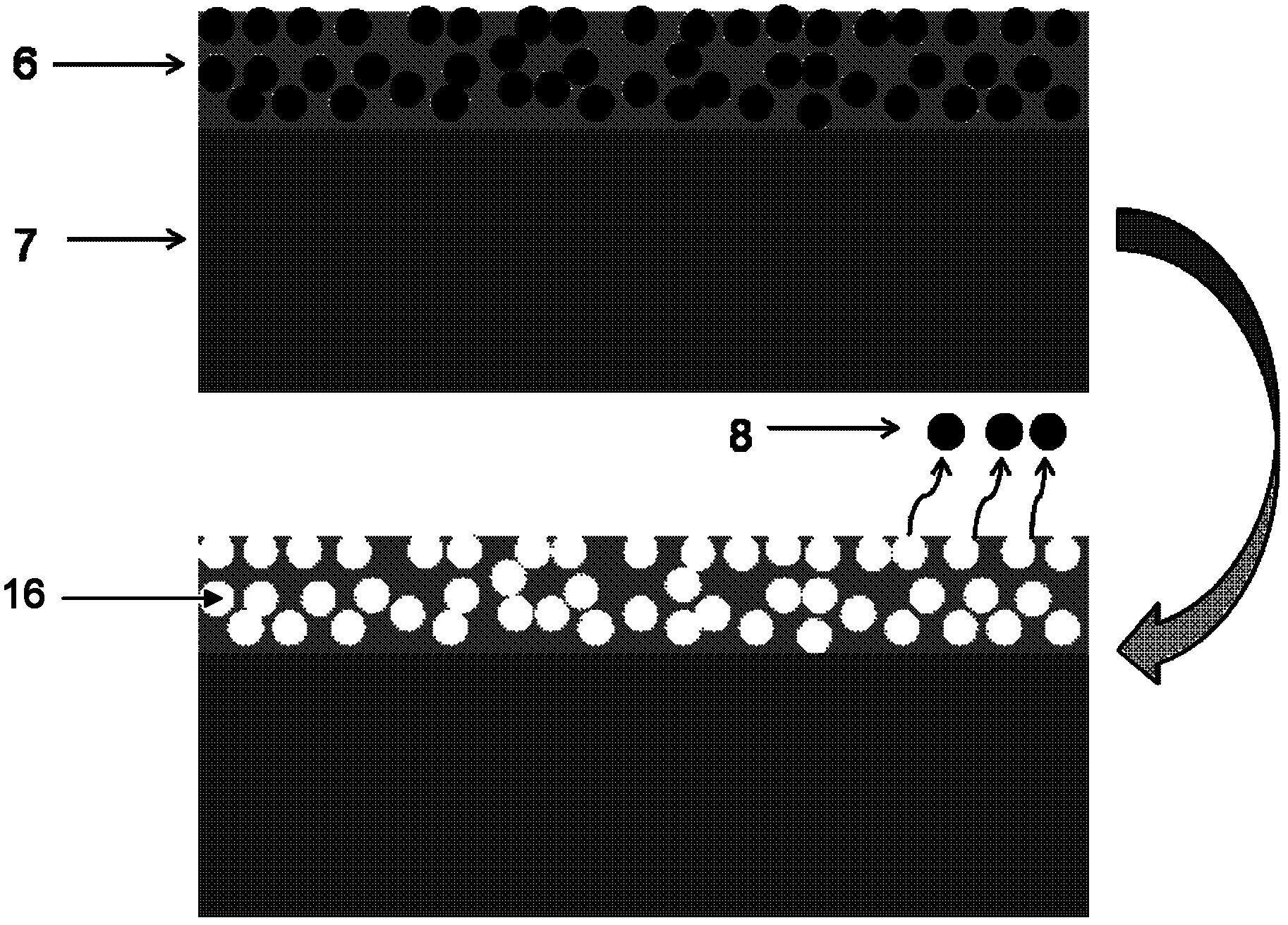

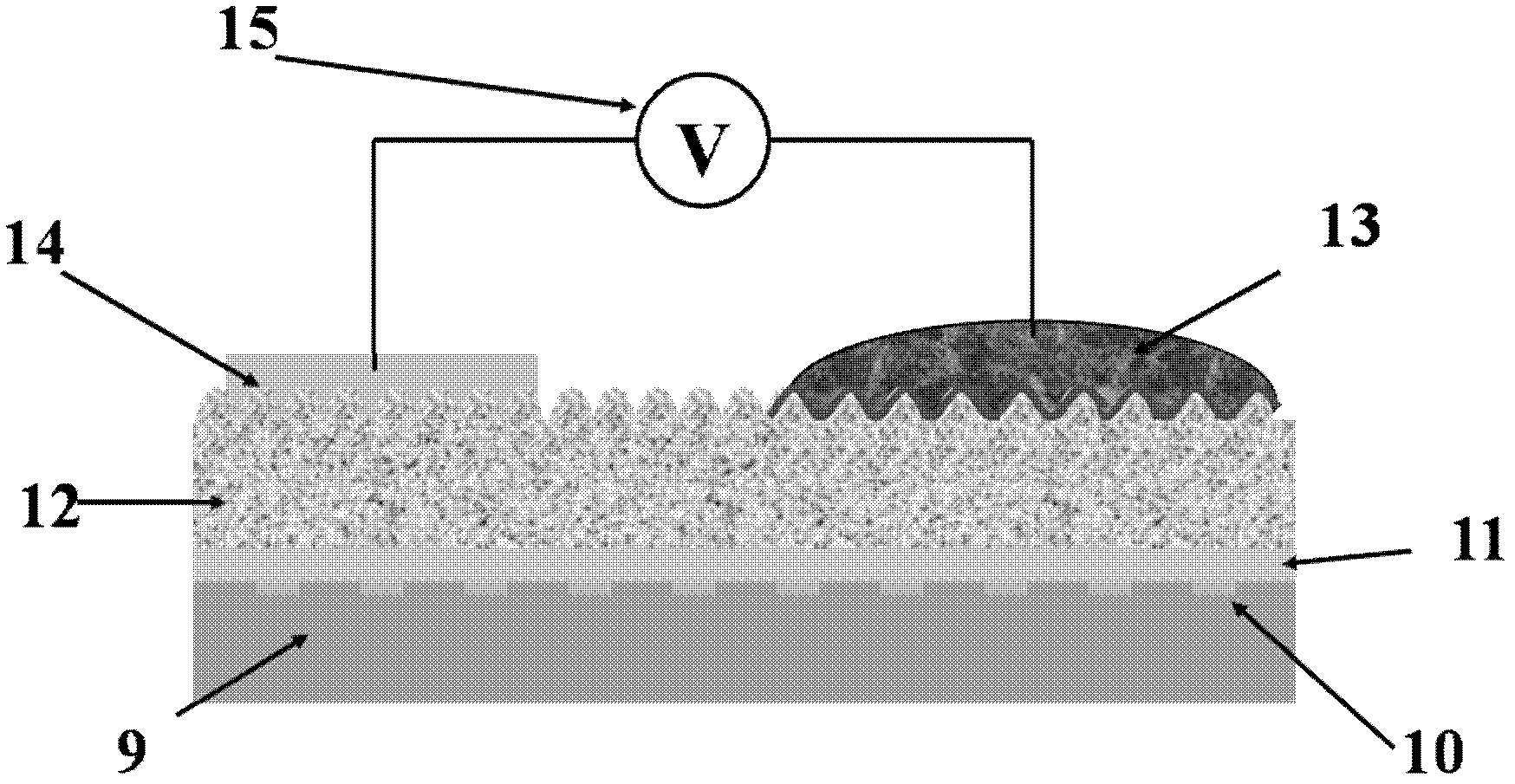

[0056] Add 5% starch to YSZ powder as a pore-forming agent, use double-layer casting and pore-forming technology to obtain a YSZ substrate, and use MnCr 2 o 4 As a sensitive electrode, Pt is used as a reference electrode to make a mixed potential type NO 2 Sensor, its specific production process:

[0057] 1. Make the YSZ substrate of the sensor. Two slurries, slurry A and slurry B, were prepared. Select commercially available YSZ powder (doped with 4 grams of Y 2 o 3 ZrO 2 ) 50g, add solvent ethanol 25ml, solvent butanone 50ml, binder PVB 7g, dispersant triethanolamine 3ml, plasticizer DE P12ml, stir to obtain slurry A without starch.

[0058] Slurry B is based on the slurry A, and then add 2.5g of starch, stir evenly to obtain slurry B with added starch.

[0059] After the two kinds of slurries were ball milled for 12 hours, 7 g of binder PVB were added again, ball milled for another 12 hours, placed in a vacuum mixer, and vacuum defoamed for 1 hour.

[0060] The fron...

Embodiment 2

[0074] Add 10% starch to the YSZ powder as a pore-forming agent, and the rest of the operating steps and conditions are the same as in Example 1.

[0075] Table 2 lists the devices made with 10% starch and pore-forming YSZ substrates at different concentrations of NO. 2 The difference between the electromotive force in the atmosphere and the electromotive force in the air (ΔEMF) varies with NO 2 As can be seen from the table, the sensitivity of the sensor is improved by adding 10% pore-forming agent to the double-layer casting slurry, and it can be compared with Table 1 in Example 1. It was found that the difference in electromotive force (ΔEMF) was significantly higher than that of the sensor with 5% starch content.

[0076] Table 2. The ΔEMF of the devices made of YSZ substrates without pores and with 10% starch pores as a function of NO 2 change in concentration

[0077]

Embodiment 3

[0079] Add 15% starch to the YSZ powder as a pore-forming agent, and the rest of the operating steps and conditions are the same as in Example 1.

[0080] Table 3 lists the devices without pores and with 15% starch pore-forming YSZ substrates at different concentrations of NO 2 The difference between the electromotive force in the atmosphere and the electromotive force in the air (ΔEMF) varies with NO 2 As can be seen from the table, the sensitivity of the sensor is improved by adding 15% pore-forming agent to the double-layer casting slurry, and it can be compared with Example 1 and Example 2. It was found that the difference in electromotive force (ΔEMF) was significantly higher than that of the sensors with starch content of 5% and 10%. Taking the measurement of 500ppm as an example, the ΔEMF of Example 3 is increased by 25mV compared with that of the comparative example.

[0081] Table 3. The ΔEMF of the sensors made of YSZ substrates without pores and with 15% starch po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com