Method for non-contact measuring center to center distance of lens optical surfaces and measuring device

A technology of optical surface and center distance, applied in the field of optical measurement, can solve the problems of cumbersome operation and heavy workload, and achieve the effect of simple data processing and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

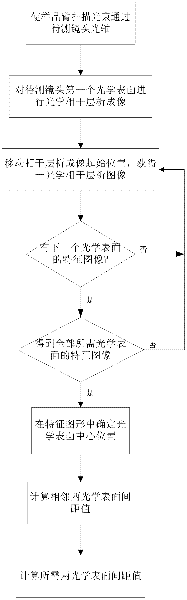

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

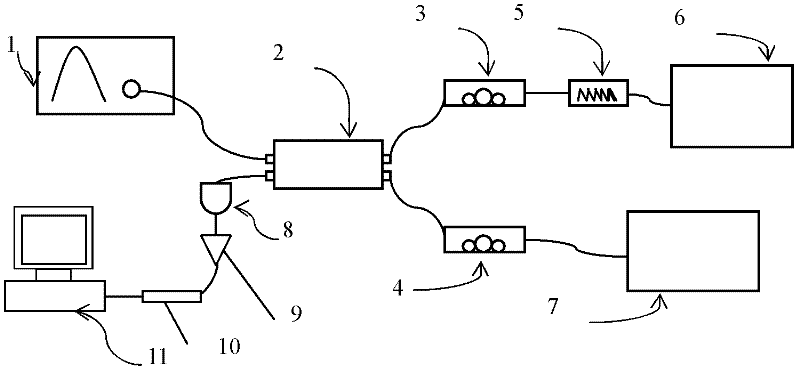

[0040] like figure 2 As shown, the device of the present invention includes a broadband light source 1, a fiber coupler 2, polarization controllers 3, 4, a phase modulator 5, an optical delay line 6, a sample scanning device 7, a photodetector 8, a low-noise preamplifier 9, Data acquisition card 10, computer 11.

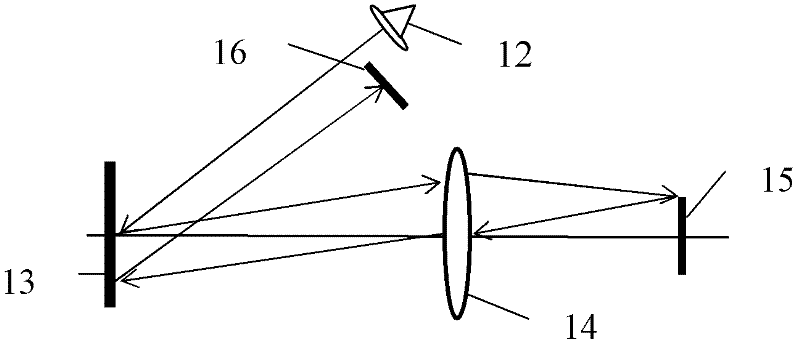

[0041] The measurement device adopts a fiber-optic Michelson interference structure. The light emitted from the broadband light source 1 is split by the fiber coupler 2 and enters the reference arm and the sample arm respectively. The way into the reference arm passes through the polarization controller 3, the phase modulator 5, and the optical delay line 6 in turn. The optical delay line 6 is a Rapid Scan Optical Delay Line (RSOD) in the spectral domain. Straightener 12, diffraction grating 13, Fourier lens 14, scanning galvanomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com