Isolator belt pulley

A technology of pulleys and one-way devices, applied in one-way clutches, belts/chains/gears, clutches, etc., can solve the problems of short life and high failure rate, and achieve the effects of improving service life, avoiding hard friction, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

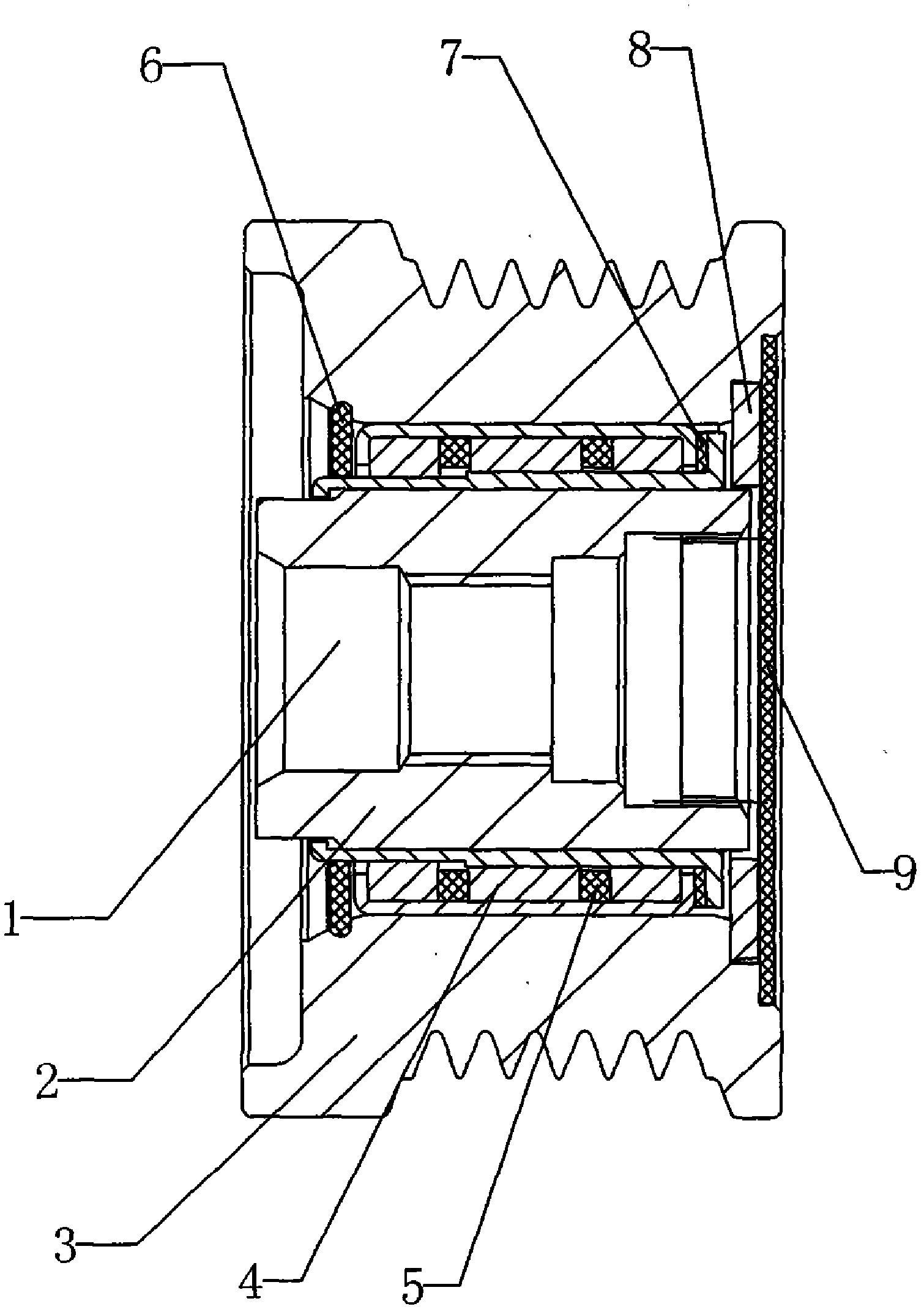

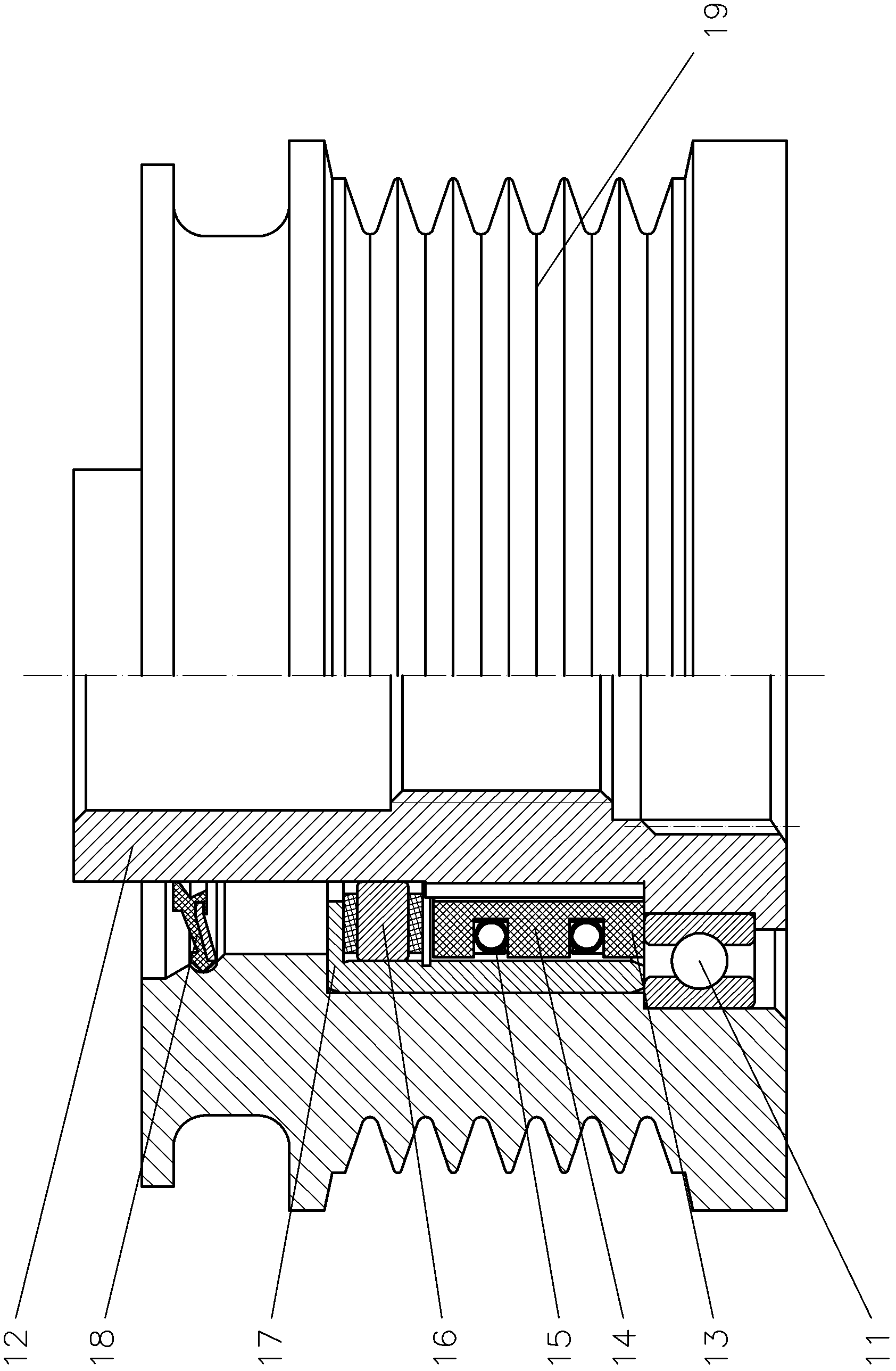

[0018] refer to figure 2 and image 3 , a kind of one-way device pulley of the present invention, comprises pulley main shaft 12, and described pulley main shaft 12 is provided with axle sleeve 17, and described axle sleeve 17 is provided with pulley outer ring 19, and described pulley outer ring 19 and pulley A spring seal ring 18 is provided between the main shafts 12; a special-shaped roller one-way cage 13 is provided between the shaft sleeve 17 and the pulley main shaft 12, and the two ends of the special-shaped roller one-way cage 13 are respectively provided with There are sealed load bearings 11 and load bearings 16 .

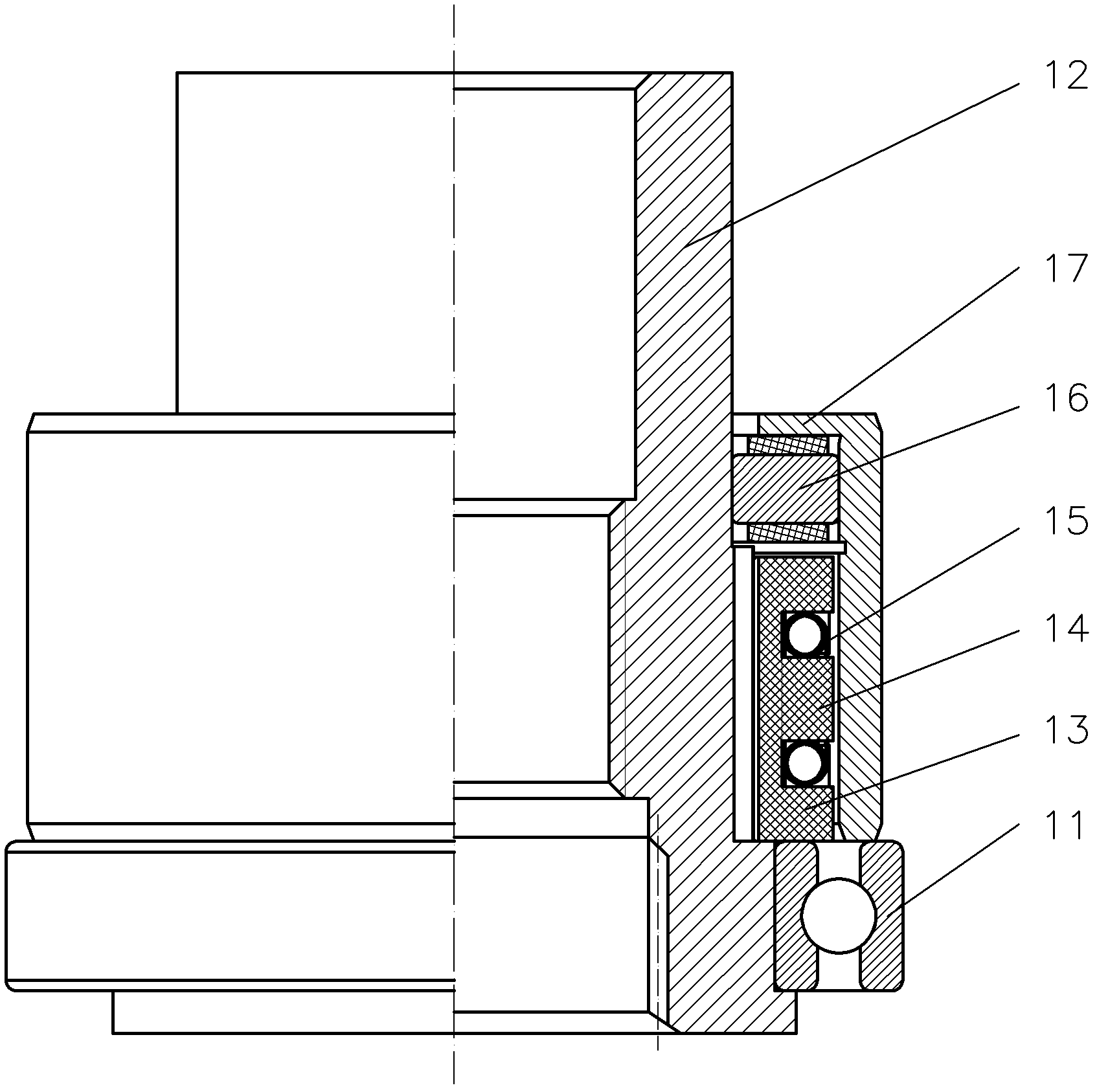

[0019] refer to Figure 4 , the special-shaped roller one-way cage 13 has a ring-shaped structure, and a group of radial through holes 1301 are evenly opened on it, and each through hole 1301 is provided with a "C" shaped special-shaped roller 14. A pair of tangential grooves 1302 are provided above each through hole 1301, and a pair of conjoined sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com