Gas well-drilling erosion experiment method

A technology of gas drilling and experimental method, applied in the direction of drilling with liquid/gas jet, etc., can solve the problems such as the inability to meet the requirements of the gas drilling annulus return velocity, the low erosion rate, and the failure of the jar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

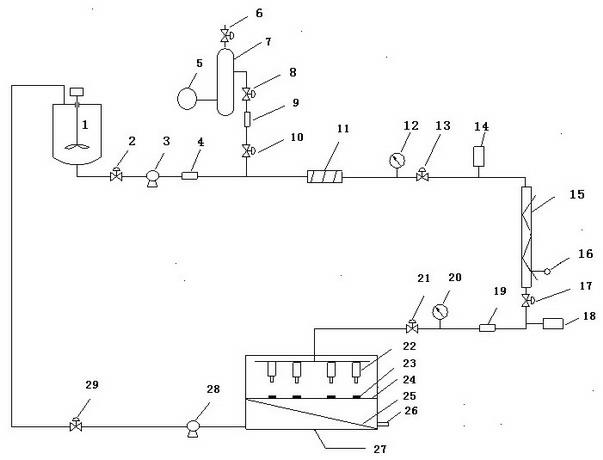

[0023] Embodiment 1 Air foam fluid erosion test method

[0024] A stable foam with a certain mass concentration is pre-prepared in the base liquid tank 1. The formula of the foam base liquid is: 0.6% K12 (the main component is sodium lauryl sulfate) + 0.2XC (biopolymer) + 0.2% HV-CMC ( high viscosity carboxymethyl cellulose) + tap water. The foam base liquid enters the porous foam generator 11 from the shut-off valve 2, the centrifugal pump 3, and the flow meter 4, and the air enters the porous foam through the air compressor 5, the air storage tank 7, the shut-off valve 8, the flow meter 9, and the shut-off valve 10 Generator 11. Adjust the gas flow rate to 0.5m 3 / min, the liquid flow rate is 8.6L / min, and the gas-liquid ratio is 58.1. Continuously add quartz sand with a particle size of 20-80 mesh from the sand adding device 14 in an amount of 80 g / min, and the sand-containing foam is heated through the cable heating pipe 15, and the foam temperature measured by the ther...

Embodiment 2

[0027] Embodiment 2 pure air erosion test method

[0028] The air enters the sand adding device 14 from the air compressor 5, the air storage tank 7, the shut-off valve 8, the flow meter 9, the shut-off valve 10, the pressure gauge 12, and the shut-off valve 13, and the air flow rate is adjusted to 0.4m 3 / min, continuously add quartz sand with a particle size of 20-80 mesh from the sand adding device 14 in an amount of 60g / min, the sand-containing air is heated through the cable heating tube 15, and the air temperature measured by the thermocouple thermometer 16 is 50°C, and the pressure gauge The reading of 20 is 1.8MPa.

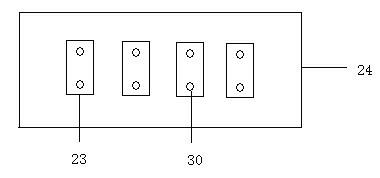

[0029] The high-temperature, high-pressure sand-containing air flowing out from the stop valve 21 enters the erosion chamber 27 . Four erosion nozzles 22 with an inner diameter of 2 mm are installed on the upper part of the erosion chamber 27, and the sand-containing air ejected through the erosion nozzles 22 scours the metal hanging piece 23 on the metal...

Embodiment 3

[0030] Example 3 Test method for erosion of brine drilling fluid filled with air

[0031] Pre-prepared a certain volume of brine drilling fluid in the base fluid tank 1, the basic formula of brine drilling fluid: 4% bentonite + 5% NaCl + 0.2% HPAM (anionic polyacrylamide) + 0.3% MMH (positive gel) + 0.5% SJ-2 (one-way plugging agent) + 0.8% SMP (fluid loss reducer) + tap water. The brine drilling fluid enters the pipeline through the stop valve 2, the centrifugal pump 3 and the flow meter 4 to mix with the air. Adjust the gas flow rate to 0.15m 3 / min, the liquid flow rate is 6.7L / min, and the gas-liquid ratio is 22.4 at this time. Continuously add quartz sand with a particle size of 20-80 mesh from the sand adding device 14 at a rate of 50 g / min. The sand-containing drilling fluid is heated through the cable heat tracing tube 15. The temperature of the drilling fluid measured by the thermocouple thermometer 16 is 50 ° C, and the pressure at the outlet end is Table 20 reads ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com