Printing and color developing method of fur

A printing and fur technology, applied in the field of leather making, can solve problems such as complex production methods, achieve good dyeing effects, reduce complexity, and reduce steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

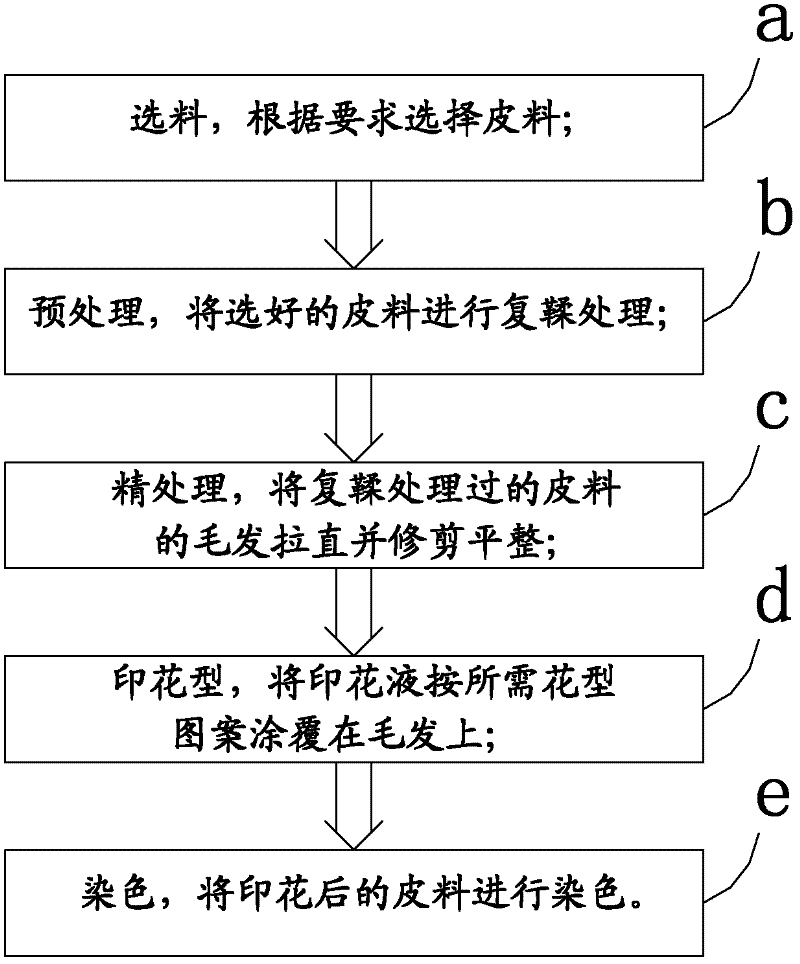

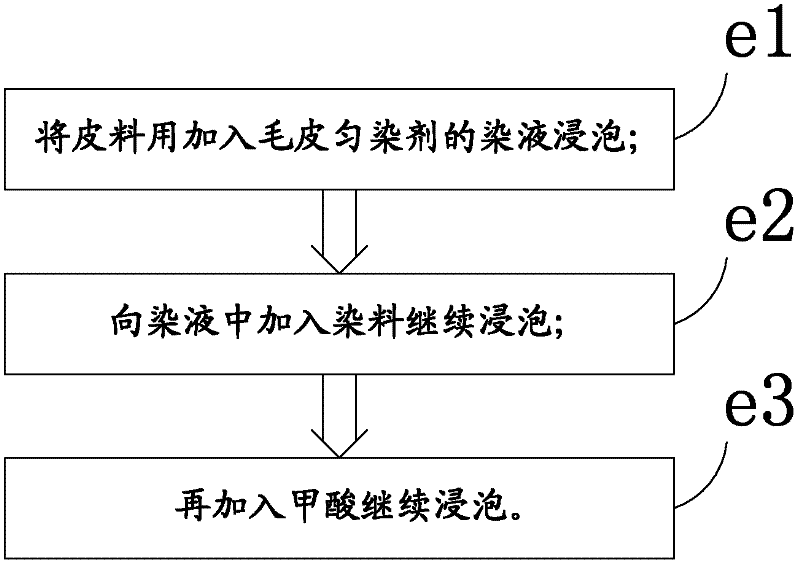

Method used

Image

Examples

specific Embodiment

[0064] Processing 100kg of sheep shearling leather with a black background and a gray complexion includes the following steps:

[0065] 101) Select sheep shearling leather with complete skin type, complete, clean wool, no knots, and no damage or rot on the skin board;

[0066] 102), first add 2000kg of water and 0.6kg of formic acid with a mass concentration of 85% to the retanning groove to make a retanning solution, put the selected leather into the groove, and soak for 30min at 35°C; Add 28kg of HLS-A type chrome tanning agent produced by Brother Technology Co., Ltd. to the solution and continue soaking for 240 minutes; finally add 2.4kg of sodium formate and soak for 8 hours to complete the retanning process. The shrinkage temperature of the leather after retanning is ≥95°C;

[0067] 103), formic acid with a mass concentration of 85%, industrial alcohol with a mass concentration of 95%, and water are made into a solution according to the ratio of 1:1:4, and evenly brushed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com