Dyeing method of reactive dye containing ionic liquid

A technology of ionic liquids and reactive dyes, which is applied in dyeing methods, textiles and papermaking, etc., can solve the problems of increasing the difficulty of dyeing wastewater with reactive dyes, the easy color difference of dyed fabrics, and the low utilization rate of reactive dyes, so as to achieve high dye utilization rate, Improving the directness and penetration, reducing the effect of dyeing and fixing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

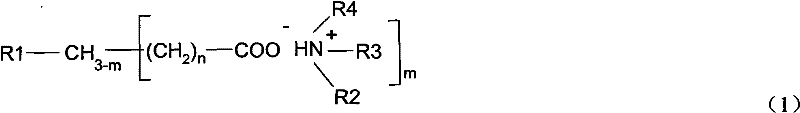

Image

Examples

Embodiment 1

[0018] Add 0.1mol ethanolamine ethanol solution into a 250ml three-necked flask, slowly add lactic acid solution with the same mole number drop by drop with a dropping funnel under rapid stirring, control the dropping process for about 30-60min, during the dropping process, the solution turns from colorless to transparent Turned into a pale yellow clear solution. Raise the temperature to reflux and react for 24 hours. After the reaction was completed, the temperature was lowered to room temperature, and the stirring was stopped. The solvent ethanol was removed by evaporation with a rotator to obtain a light yellow viscous liquid. Put it into a vacuum drying oven and dry at 50°C for 48 hours. The yield of the product ionic liquid was 83%.

Embodiment 2

[0020] Add 0.3mol triethanolamine ethanol solution into a 250ml three-necked flask, slowly add 0.1mol citric acid ethanol solution drop by drop with a dropping funnel under rapid stirring, control the dropping process for about 30-60min, and heat up to reflux after dropping Under the state of reaction for 12-18 hours. After the reaction was completed, the temperature was lowered to room temperature, and the stirring was stopped. Separation with a separatory funnel, the product is a light yellow viscous liquid, put it into a vacuum drying oven, and dry at 50° C. for 48 hours, and the yield of the ionic liquid is 92%.

Embodiment 3

[0022] (1) Cotton fabric dyeing process containing ionic liquid

[0023] Adopt active orange K-G, active bright orange K-7R or active red K-3B, consumption is 2% (mass percentage, weight to cotton fiber), ionic liquid concentration 10-20g / L, dyeing temperature 60 ℃, bath ratio 1: 10. Dyeing time is 40min, then add sodium carbonate 20-40g / L, fix color at 60°C for 50min, wash twice with water, soap wash (95°C, soap flakes are 3g / L), 10min, wash with water and dry.

[0024] (2) Conventional cotton fabric dyeing process

[0025] Use reactive orange K-G, reactive brilliant orange K-7R or reactive red K-3B, the dosage is 2% (mass percentage, weight to cotton fiber), the concentration of sodium chloride is 40g / L, the dyeing temperature is 60°C, and the bath ratio is 1:10 , dyeing time 40min, then add sodium carbonate 20-40g / L, heat up to 90°C, fix color time 50min, wash twice with water, soap wash (95°C, soap flakes are 3g / L), 10min, wash with water and dry.

[0026] See Table 1 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com