Gasoline desulfuration and deodorization process

A gasoline and deodorization technology, applied in the field of gasoline purification treatment, can solve the problems of limited long-term operation of the device, large waste alkali discharge, insufficient mass transfer efficiency, etc., to achieve long-term operation, increase processing load, and reduce the amount of activator Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

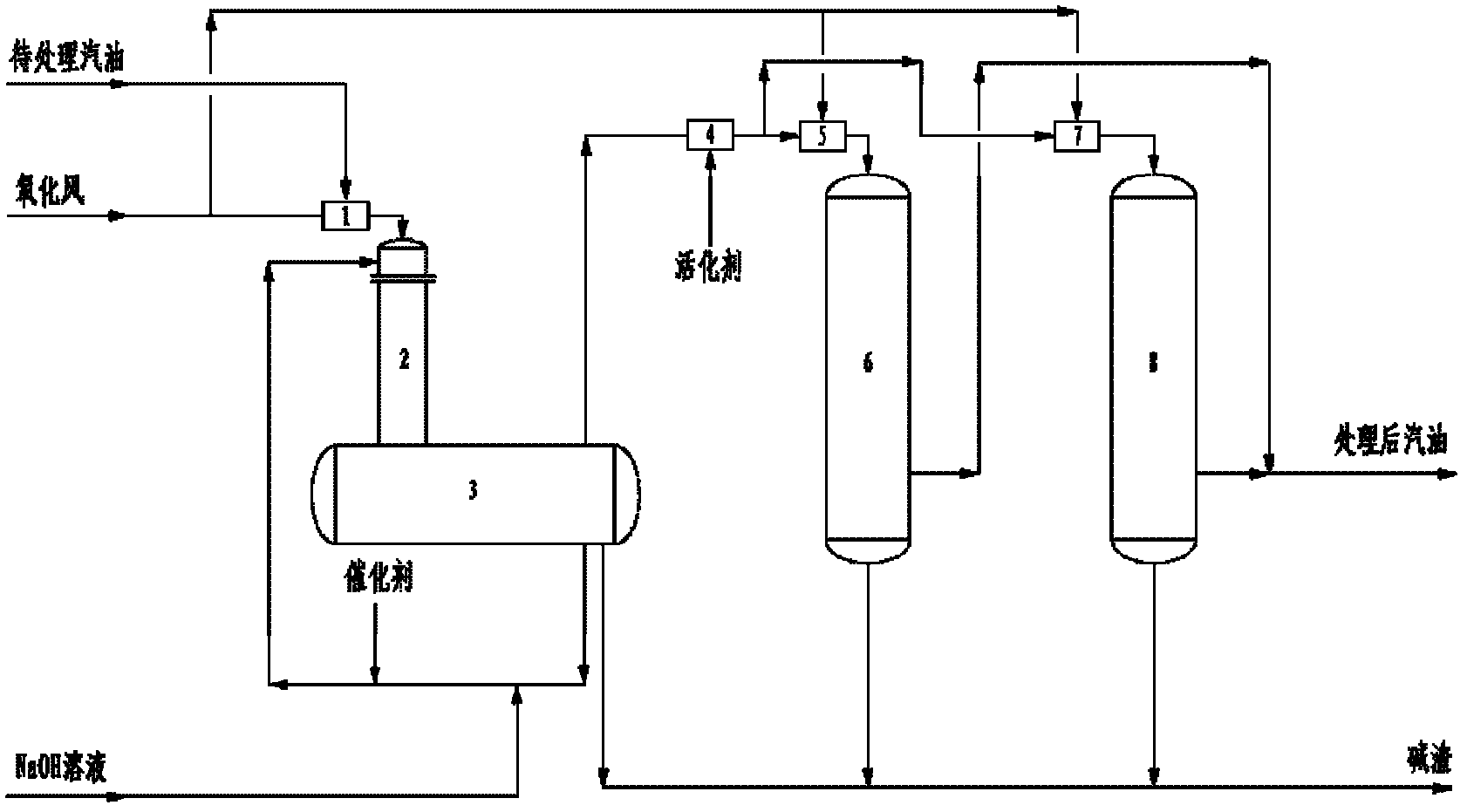

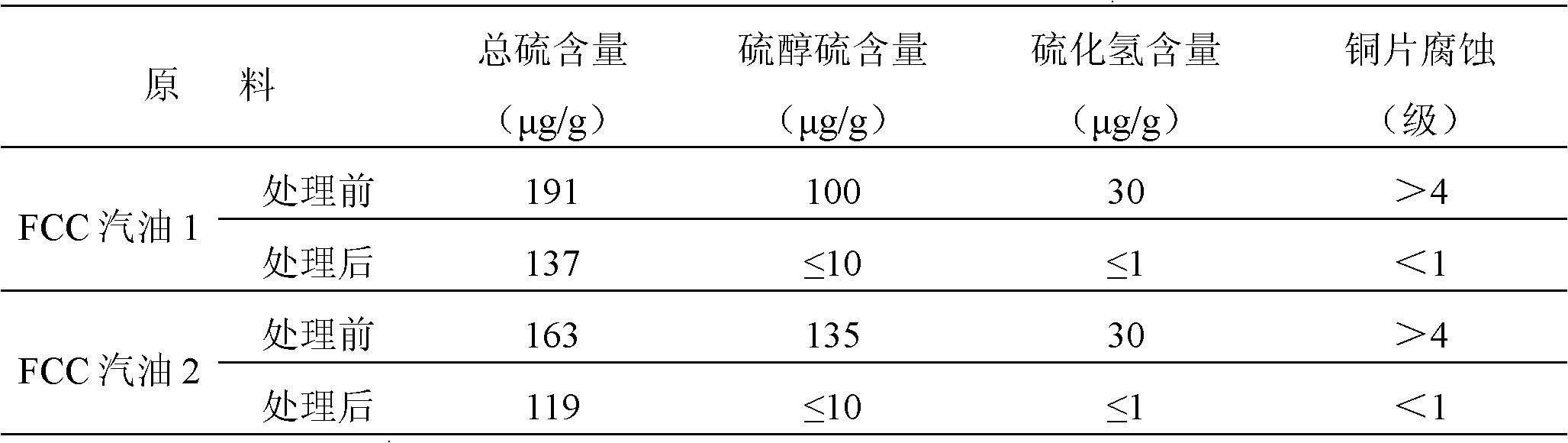

[0037] Such as figure 1 As shown, the gasoline to be processed and the oxidizing wind enter the top of the fiber liquid membrane reaction device 2 after passing through the gasoline / oxidizing wind mixer 1, and the circulating NaOH solution from the bottom of the sedimentation separation tank 3 completes the hydrogen sulfide and mercaptan in the gasoline. To remove the oxidation reaction with sodium mercaptan, the catalyst sulfonated cobalt phthalocyanine is added to the circulating NaOH solution through the pipeline. In this process, the hydrogen sulfide in the gasoline is extracted into the NaOH solution, and the mercaptans in it are sequentially extracted to form sodium mercaptide, oxidized to form disulfides, and disulfides are back-extracted into the gasoline. So as to realize the desulfurization and deodorization of gasoline. The fiber liquid membrane reaction device 2 is a fiber liquid membrane reaction device described in the Chinese patent with the patent number ZL20102...

Embodiment 2

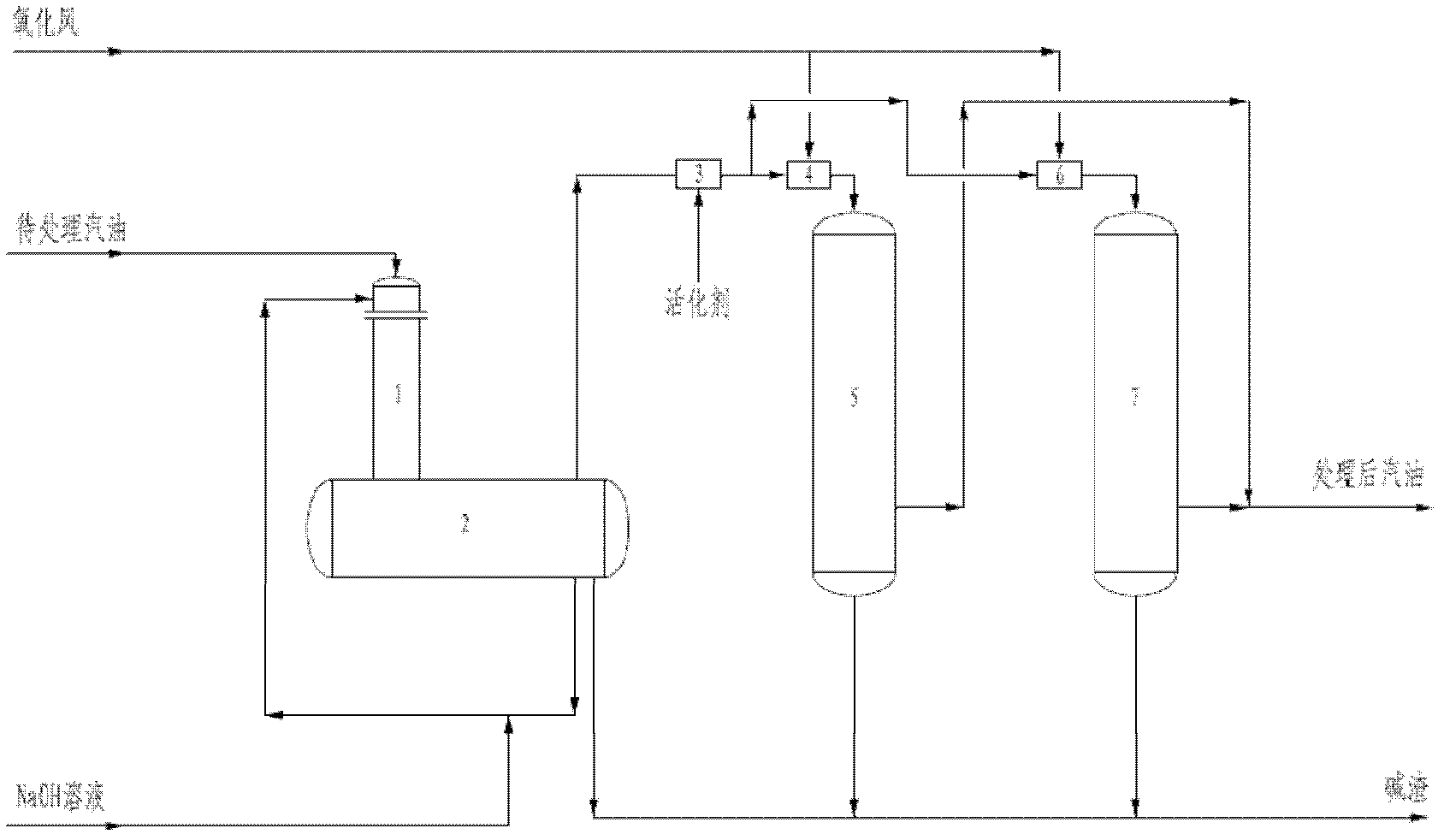

[0046] Such as figure 2 As shown, the gasoline to be processed enters the top of the fiber liquid membrane reaction device 1, and the circulating NaOH solution from the bottom of the sedimentation separation tank 2 completes the removal reaction of hydrogen sulfide and mercaptans in the gasoline. In this process, the hydrogen sulfide and most mercaptans in the gasoline react with NaOH to form sodium sulfide and corresponding sodium mercaptide and enter the NaOH solution, thereby achieving the desulfurization of the gasoline. The fiber liquid membrane reaction device 1 is a fiber liquid membrane reaction device described in the Chinese patent with the patent number ZL201020266679.6.

[0047] The reacted gasoline and lye are settled and separated in the sedimentation separation tank 2, and the NaOH solution discharged from the bottom is recycled. The gasoline discharged from the top and the activator ZH-22 pass through the activator mixer 3 and then pass through the gasoline / Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com