Enhanced plugging material for steel sheet piling cofferdam and its preparation and application method

A technology for steel sheet pile cofferdams and leak-stopping materials, applied to sheet pile walls, chemical instruments and methods, and other chemical processes, can solve problems such as increased construction time, water leakage and water seepage at difficult steel sheet pile joints, and achieve operational construction Convenience, excellent fluidity and cohesiveness, the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prepare the steel sheet pile cofferdam reinforcement plugging material according to the following steps

[0044] ①. Dehydration

[0045] Put 80 parts by weight of polyoxypropylene diol 330N with a relative molecular mass of 5000±200 terminated with ethylene oxide, and 10 parts by weight of polyoxyethylene tetrahydric alcohol SD101 with a relative molecular mass of 9800±200, put them into the polymerization reactor, and start stirring , heat up to 80-100°C, dehydrate for 2-3 hours under vacuum, remove trace moisture in the polymer polyol and the reaction system, cool down to 10-40°C, and prepare the polyurethane prepolymer;

[0046] ②. Preparation of polyurethane prepolymer

[0047] Under stirring, put 0.01 parts by weight of retarder phosphoric acid, 9 parts by weight of toluene diisocyanate TDI, and 1 part by weight of polyphenylpolymethylene polyisocyanate PAPI into the reaction system after dehydration in step ① in sequence, at 80-85 ° C Under high temperature, rea...

Embodiment 2~ Embodiment 5

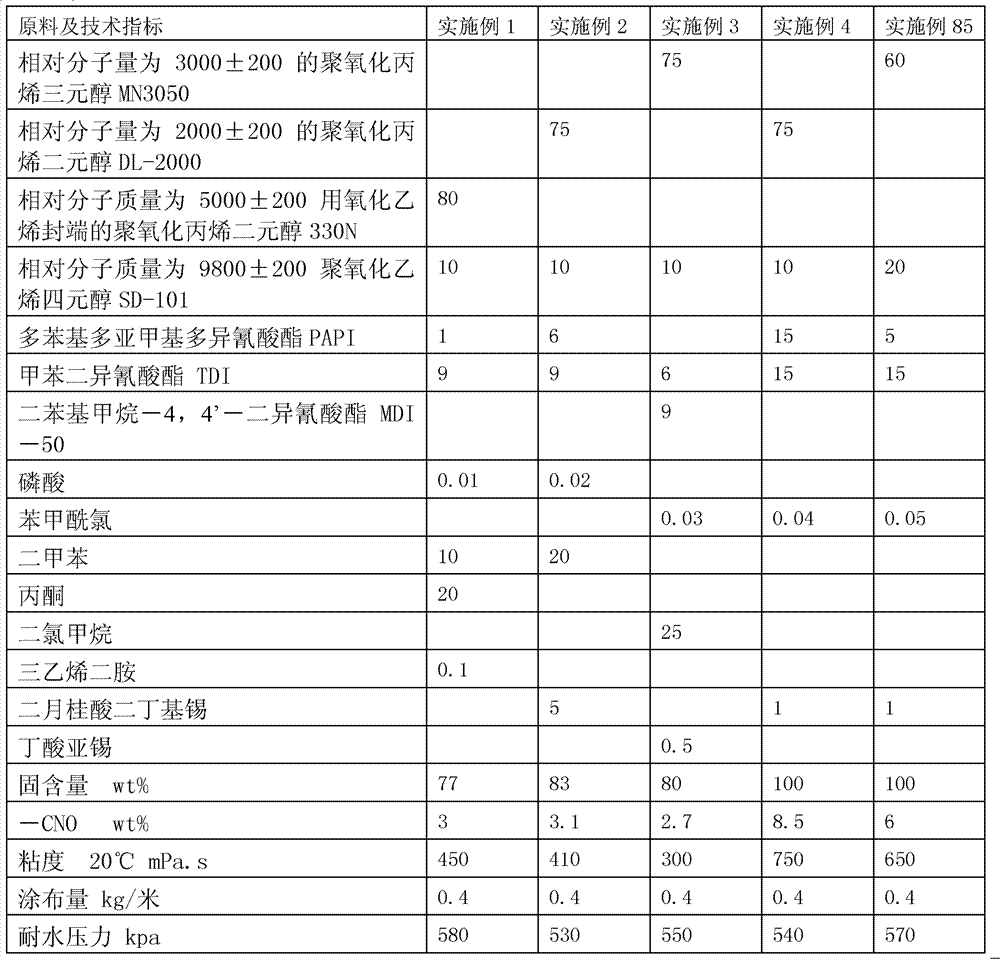

[0051] According to the method and steps of Example 1, prepare the steel sheet pile cofferdam reinforcement plugging material of the present invention according to the formula in Table 1

[0052] Table 1

[0053]

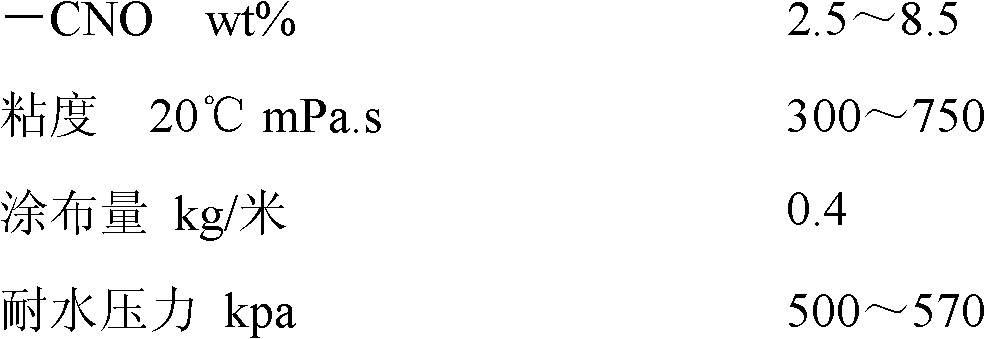

[0054] The steel sheet pile cofferdam reinforced plugging material prepared in Examples 1 to 5 has a viscosity of 300--750mPa.s at 20°C, which ensures good fluidity of the material liquid, and the single-component glue is easy to use, and the film after expansion can The water resistance pressure is 500-570kpa, which is equivalent to no water leakage at a water depth of 50-60 meters; the experiment in 3% saline artificial seawater also meets the above technical indicators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com