AM mixture used for wood plastic products, and preparation and application methods thereof

A technology for wood-plastic products and mixtures, applied in the field of chemical synthesis, can solve the problems of weather resistance shackles and other problems, and achieve the effects of excellent processing characteristics, excellent impact resistance and tensile strength, and enhanced impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

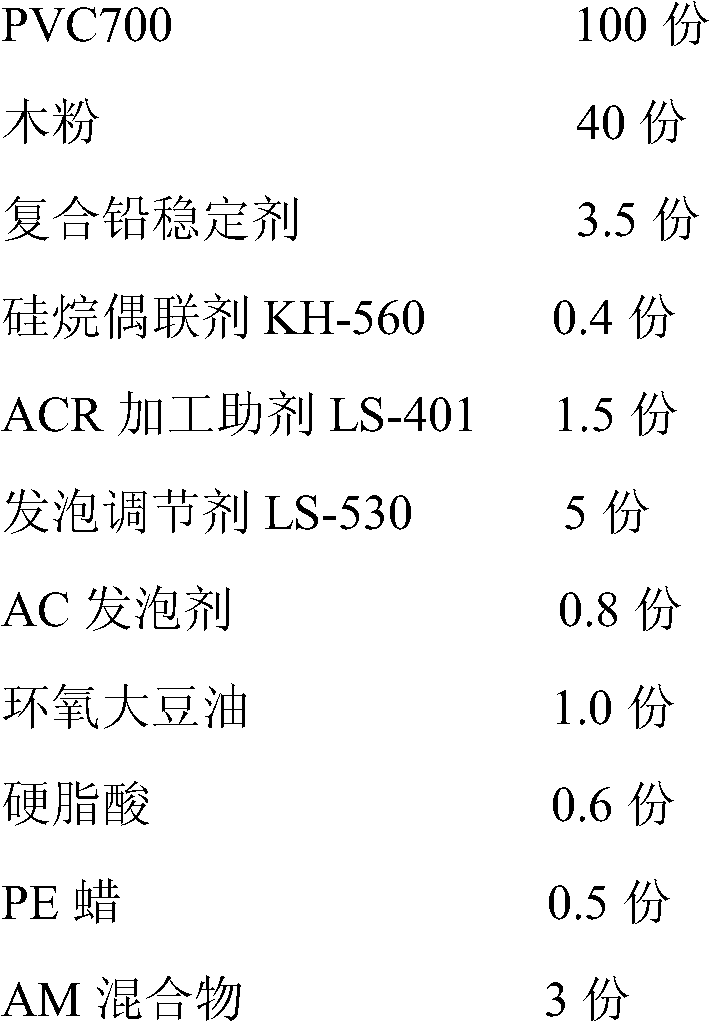

Embodiment 1

[0032] (1) Preparation of AM mixture:

[0033] Synthesis of acrylate monomer emulsion: add 6g sodium lauryl sulfate, 3g potassium persulfate, 100g deionized water into the reaction kettle, stir and pass nitrogen, add 225.6g methyl methacrylate, 56.4 g butyl acrylate with Na 2 SO 4 The pH value of the emulsion is adjusted by the solution to 8, and the temperature is kept at 50° C. for 2 hours, and the temperature is lowered to obtain an acrylate monomer emulsion;

[0034]Preparation of AM mixture: Add 200 g of deionized water, 12 g of sodium lauryl sulfate, 12 g of potassium persulfate and 818 g of acrylate monomer emulsion prepared in the previous step into a stainless steel autoclave, containing 282 g of acrylate monomer, Use 5% to 10% NaOH solution to adjust the pH value of the mixed reaction solution in the range of 9 to 11, then add 18g of crosslinking agent DCP and silane coupling agent KH-560, fill with nitrogen, vacuumize and exhaust oxygen, repeat 3 times, then add ...

Embodiment 2~3

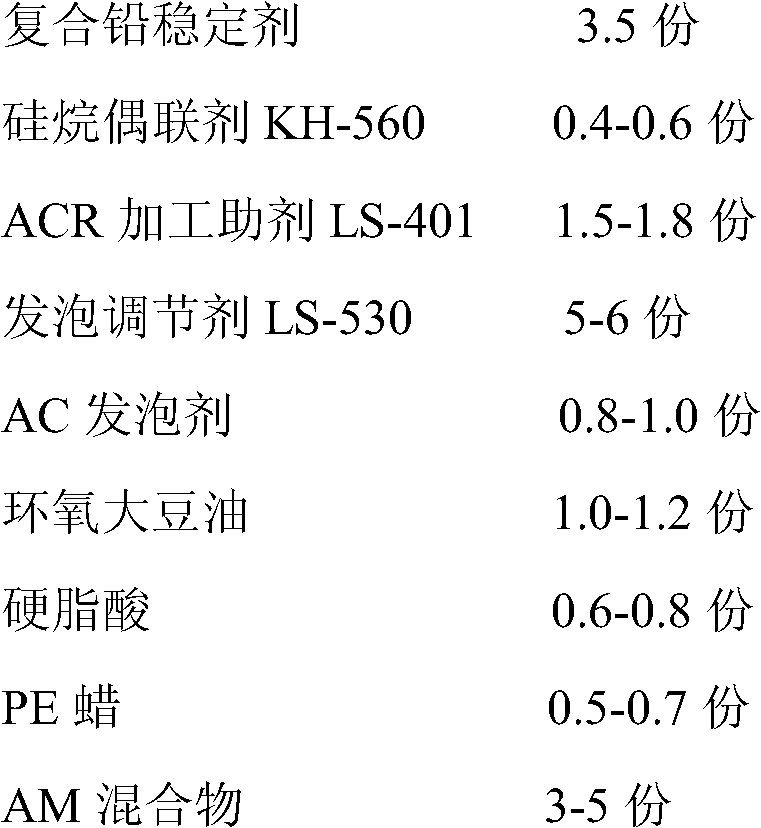

[0042] The conditions and proportions of the synthetic AM mixture have changed, and the formula for producing wood-plastic foam board has changed. The specific formula is shown in Table 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com