Efficient composite liquid cement grinding aid and preparation method thereof

A cement grinding aid and liquid technology, applied in the field of grinding aids, can solve the problems of restricting the excessive use of triethanolamine, exceeding 0.03%-0.05% of concrete performance, adverse effects, etc., and achieves improved adaptability, stable quality, and increased The effect of early and late strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

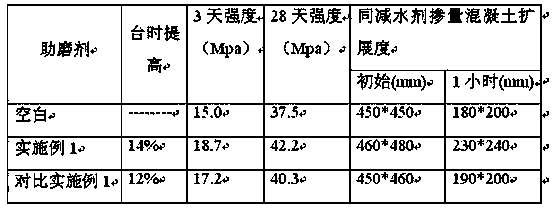

Examples

Embodiment 1

[0017] Weigh each component according to the following weight percentage: 10% triethanolamine, 15% chloropropanediol, 2% sodium acetate, 1% sodium thiosulfate, 10% sodium chloride, 2% polycarboxylate superplasticizer, 0.5% glacial acetic acid %, and the rest is water.

[0018] Inject water into the reaction kettle, add sodium acetate, sodium thiosulfate, and sodium chloride at room temperature, stir for 2 hours, add triethanolamine, 3-propylene glycol, polycarboxylate water reducer and stir for 1 hour after all dissolve, and finally add glacial acetic acid and stir After 30 minutes, the product is filtered with a 200-mesh filter and then discharged into barrels.

Embodiment 2

[0020] Each component is weighed according to the following percentages by weight: 30% of triethanolamine, 50% of 3-propylene glycol, 5% of polycarboxylate superplasticizer, and the rest is water.

[0021] Inject water into the reaction kettle, put triethanolamine, 3-propylene glycol, and polycarboxylate water-reducer at room temperature, stir for 1 hour, discharge and load into barrels after all are dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com