Plastic expanding agent used for cement base material shrinkage and compensation, its preparation method and its application

A technology of cement-based materials and plastic expansion agents, which is applied in the field of plastic expansion agents for shrinkage compensation of cement-based materials and its preparation and application, can solve problems affecting the performance and interface properties of cement-based materials, and achieve crack prevention and good compatibility The effect of high utilization rate of performance and expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

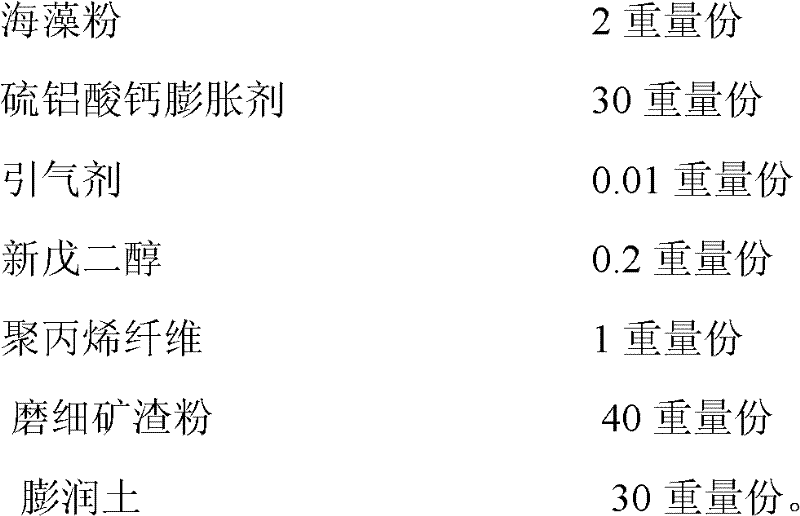

Embodiment 1

[0041]

[0042]The plastic expansion agent for shrinkage compensation of cement-based materials prepared in the above ratio is mixed into C40 concrete according to 10% of the amount of cementitious materials in ordinary concrete. The early plastic shrinkage rate of the concrete is 0%, the 28d free expansion rate reaches 0.15%, and the 28-day compressive strength is increased by 5% compared with the benchmark concrete.

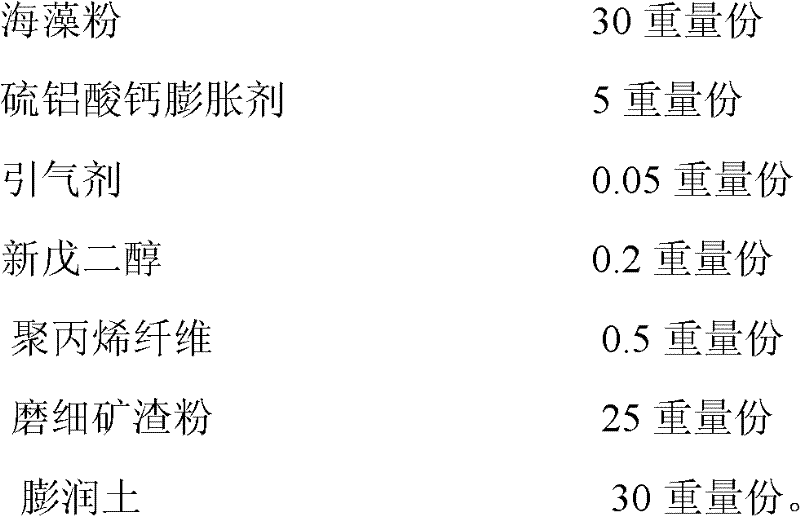

Embodiment 2

[0044]

[0045] The plastic expansion agent for shrinkage compensation of cement-based materials prepared in the above ratio is mixed into C40 concrete according to 10% of the amount of cementitious materials in ordinary concrete. The early plastic shrinkage rate of the concrete is -0.11%, the 28-day free expansion rate reaches 0.10%, and the 28-day compressive strength is 15% lower than that of the reference concrete.

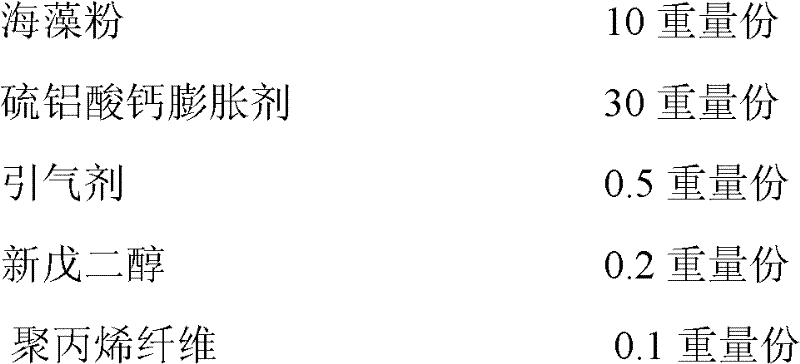

Embodiment 3

[0047]

[0048]

[0049] The plastic expansion agent for shrinkage compensation of cement-based materials prepared in the above ratio is mixed into C40 concrete according to 10% of the amount of cementitious materials in ordinary concrete. The early plastic shrinkage rate of the concrete is -0.05%, the 28-day free expansion rate reaches 0.15%, and the 28-day compressive strength is 18% lower than that of the benchmark concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com