Tower crane introducing platform structure

A platform structure and tower crane technology, applied in cranes and other directions, can solve the problems of inconvenient turning, potential safety hazards, platform shaking, etc., and achieve the effects of improving operation safety, improving application safety, and introducing simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

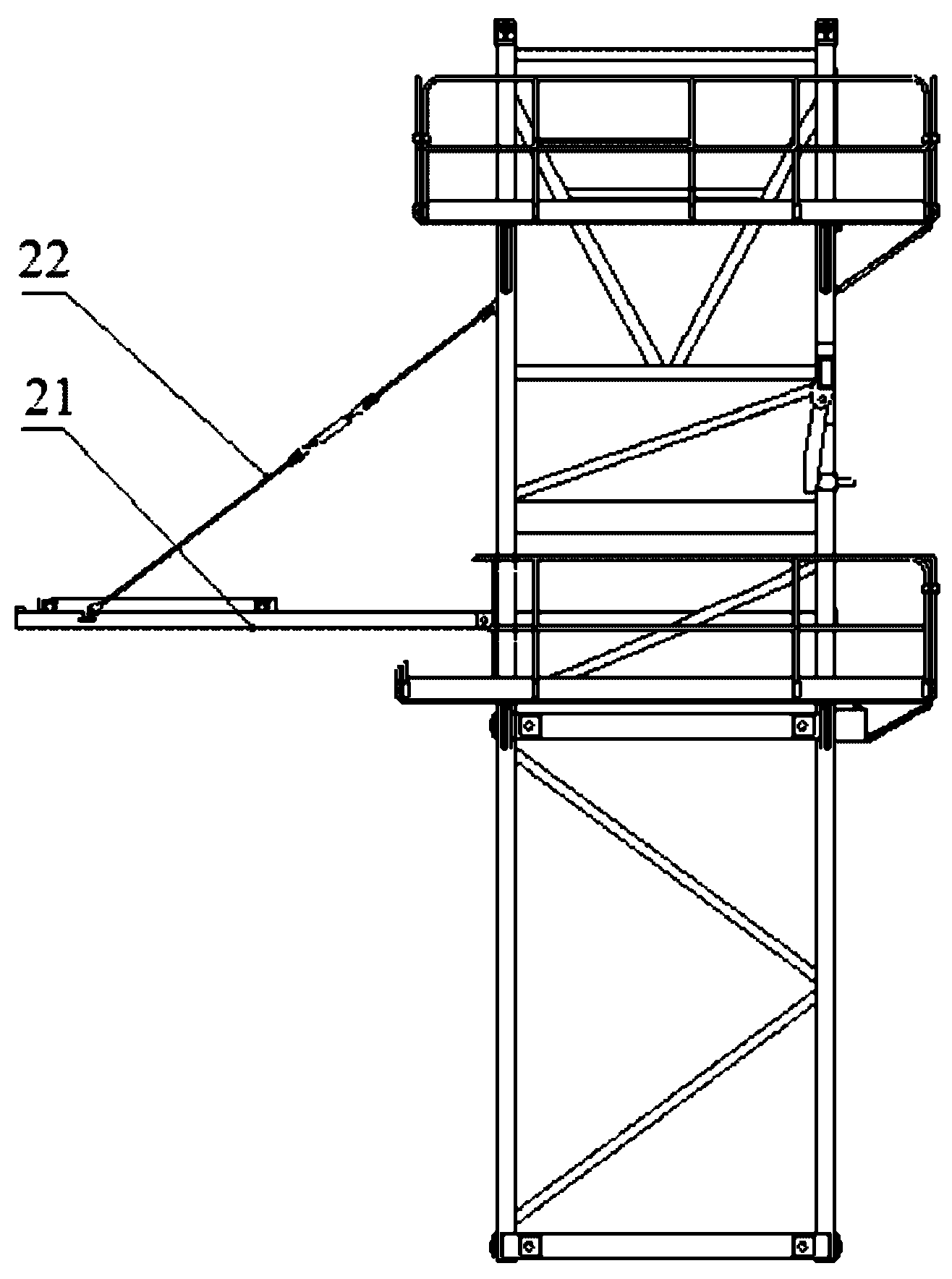

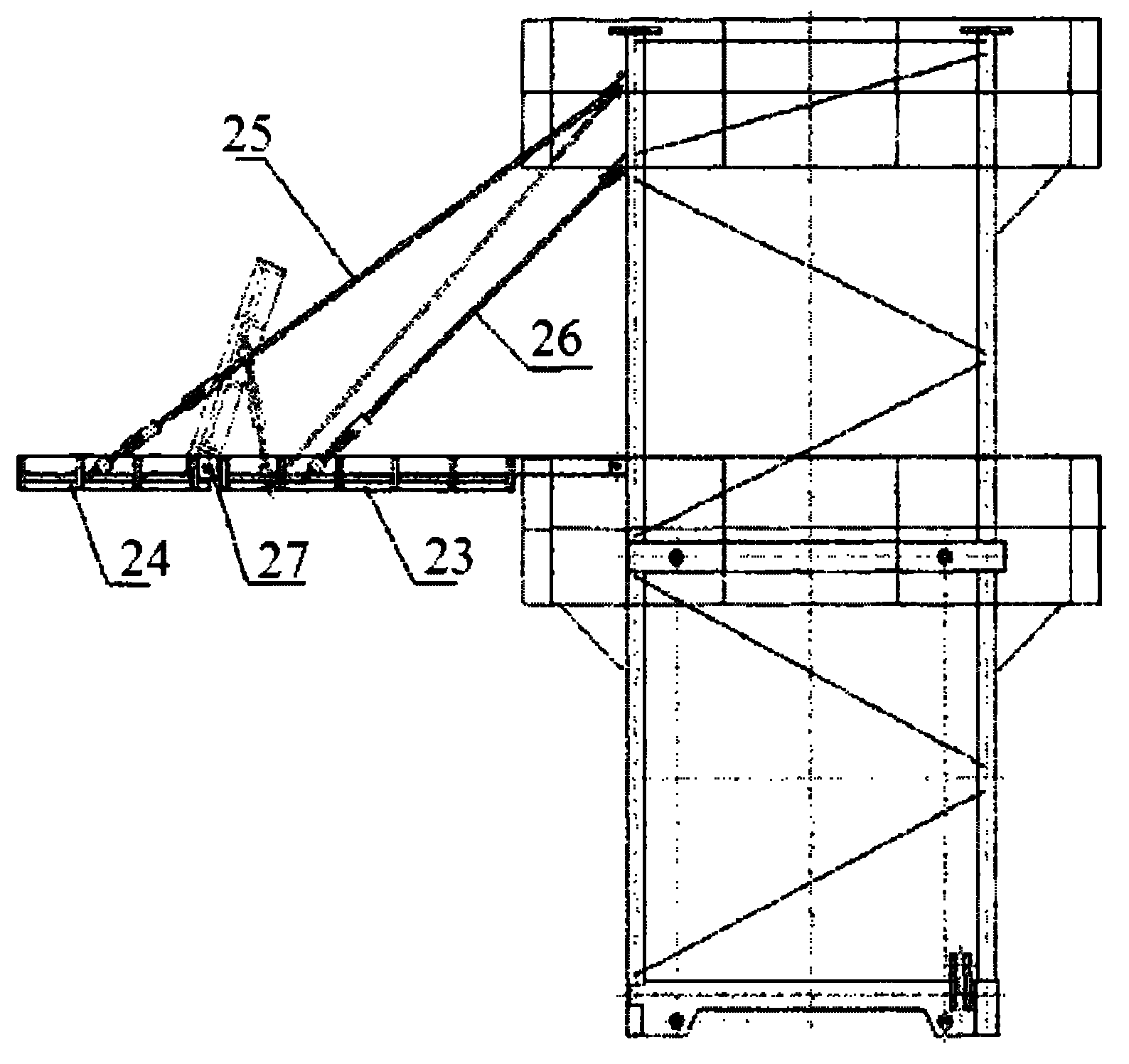

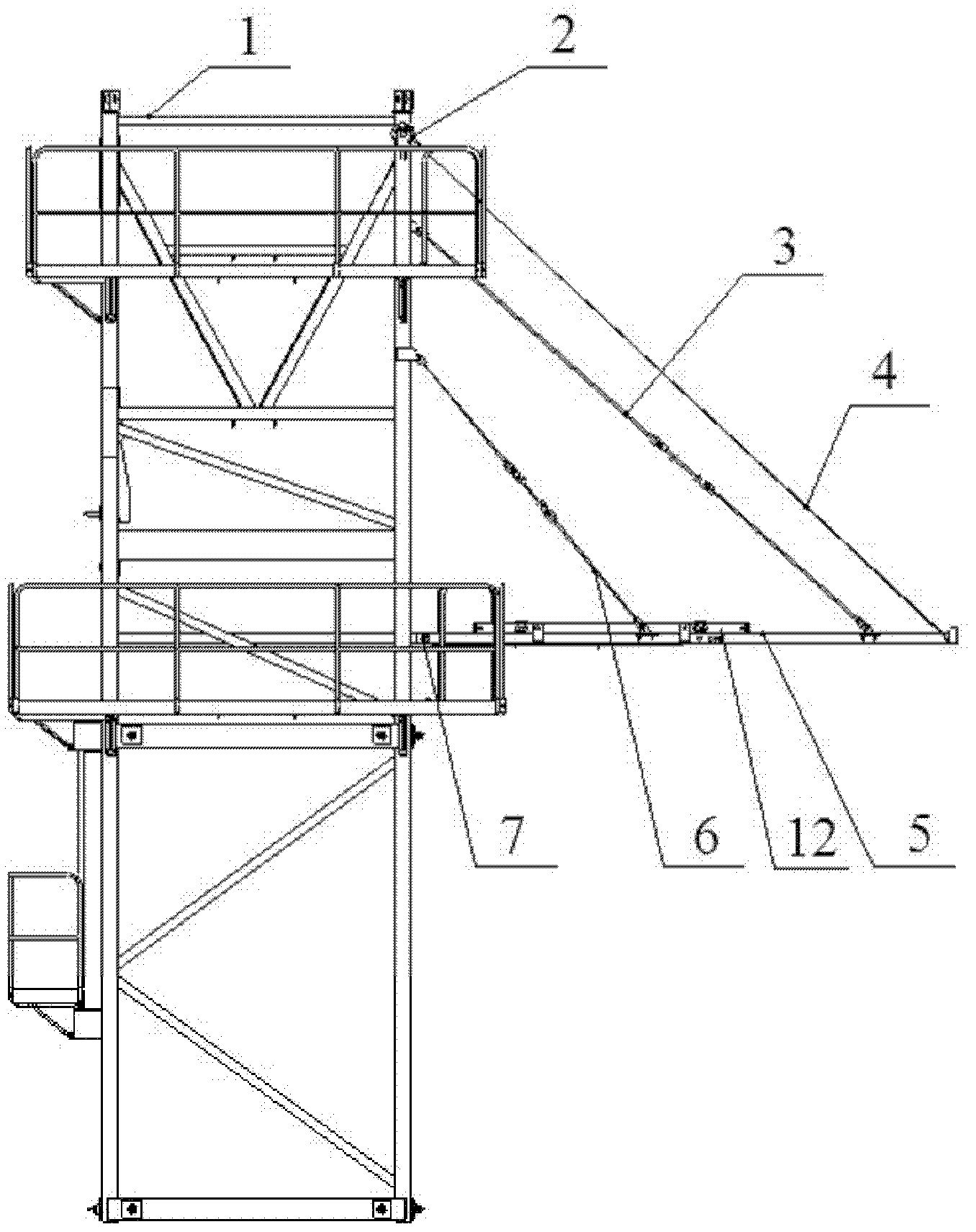

[0027] image 3 shows a schematic side view of the long arm of the tower crane introduction platform structure according to an embodiment of the present invention. The introduction platform structure of the tower crane of the present invention includes three main parts: the introduction platform 5, the long tie rod 3, the short tie rod 6 and the turning and lifting mechanism 2, wherein the pull rod can be a pull rod composed of three sections, and the pull rod is designed to be foldable. It can also be a flexible cable. The rigid introduction platform 5 is hinged with the main structure 1 of the climbing frame of the tower crane with a pin 7, and connected with the climbing frame structure 1 through two sets of flexible tie rods 3, 6 to form a stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com