Life prolonging method for quickly repairing microcracks of pump parts and life prolonging device for quickly repairing microcracks of pump parts

A technology for micro-cracks and parts, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of cladding layer microstructure, shedding, and easy occurrence of thermal cracks, etc., to achieve micro-crack strengthening and prolong service life , Improve the effect of fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

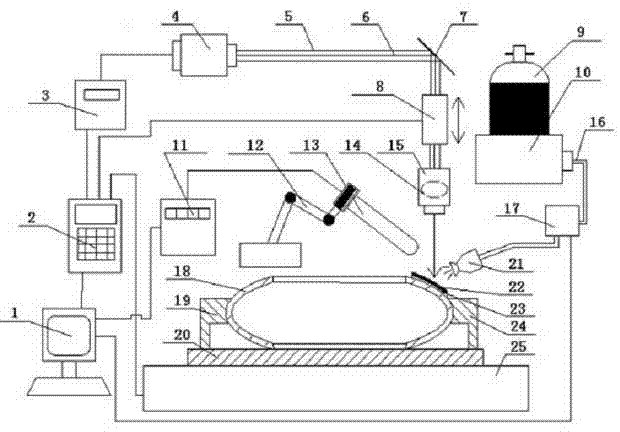

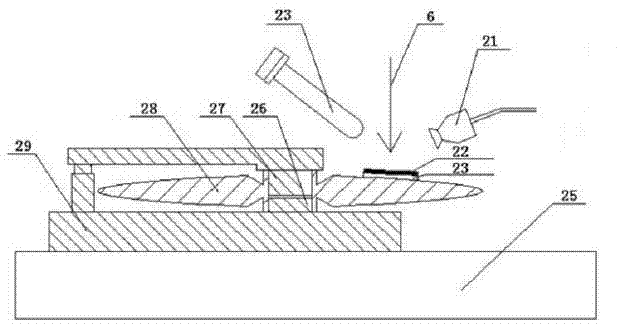

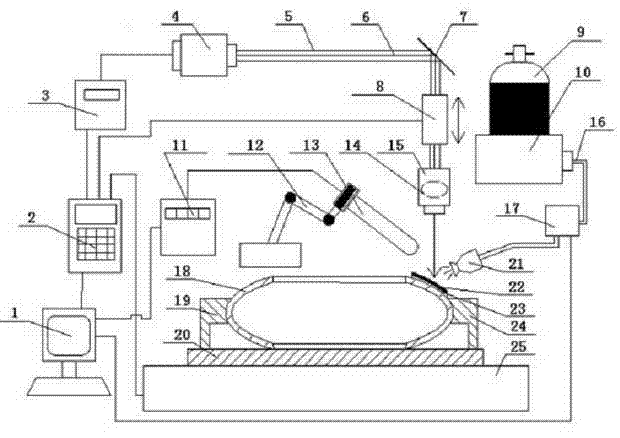

Embodiment 1

[0017] Embodiment two

Embodiment 2

[0019]After using this method to repair and repair, after inspection, the surface of the coating layer did not appear rust, cracking and falling off after the salt spray test for 1000 hours, and the life of the pump casing and blades was extended by about 1.5 times. The surface mechanical properties were tested and compared with those before treatment. In contrast, it was found that the number of cycles during crack initiation increased significantly, which greatly improved the fatigue life and played a strengthening role. At the same time, it ensures the normal operation of the pump casing and blades in water, acid-base liquid environment. The research results show that the hardness and strength of the pump casing and blades are significantly improved after the repair and strengthening, and the surface changes from the residual stress state from the tensile stress to the compressive stress state, so that its fatigue life and wear resistance are significantly improved. It is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com