Squeezing needle used for producing lubrication-free heat squeezing seamless pipe material

A seamless pipe and hot extrusion technology, applied in the field of extrusion needles, can solve the problems of uneven application of lubricating oil, oil spots on the inner surface of the pipe, and easy sticking of extrusion needles to metal, etc., to improve the quality of the inner surface and shorten the Production cycle, the effect of eliminating scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

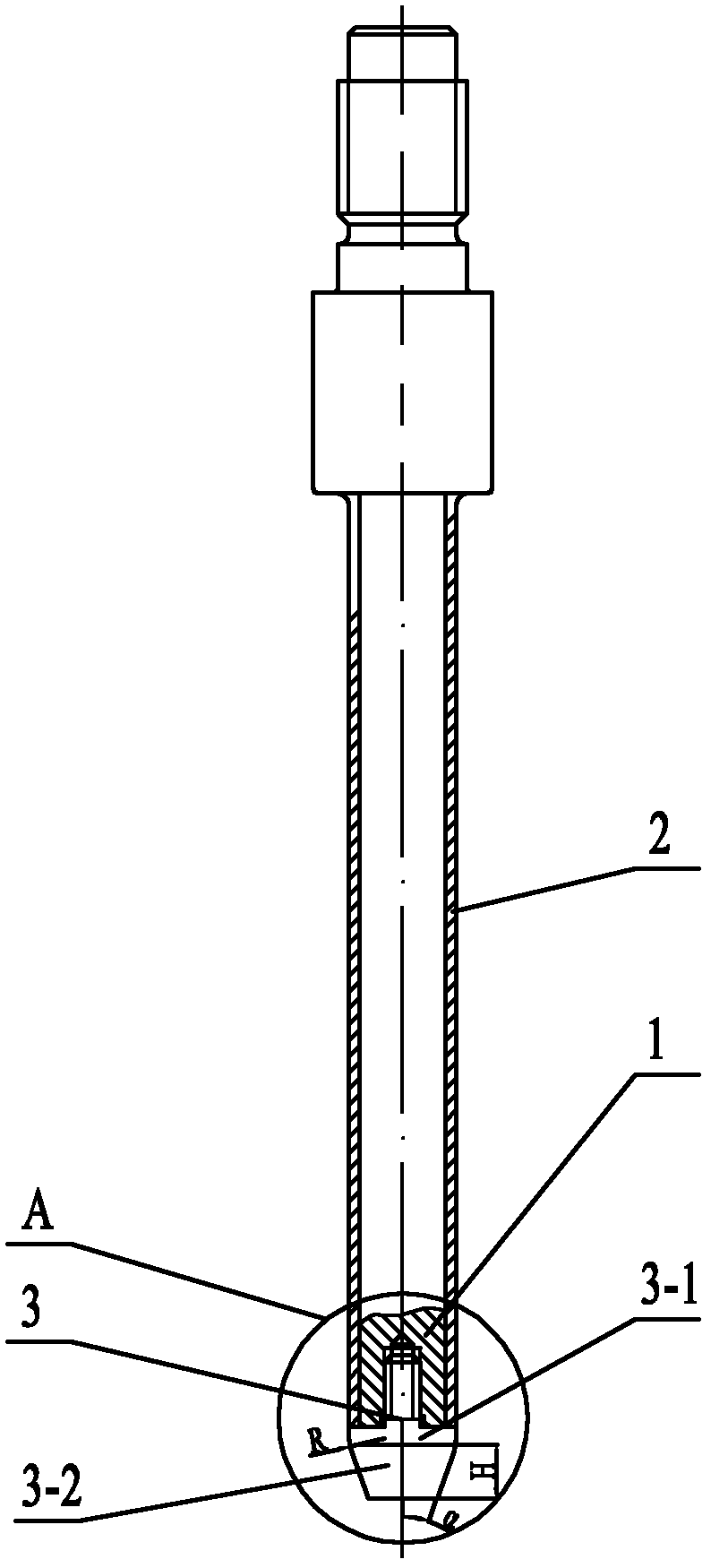

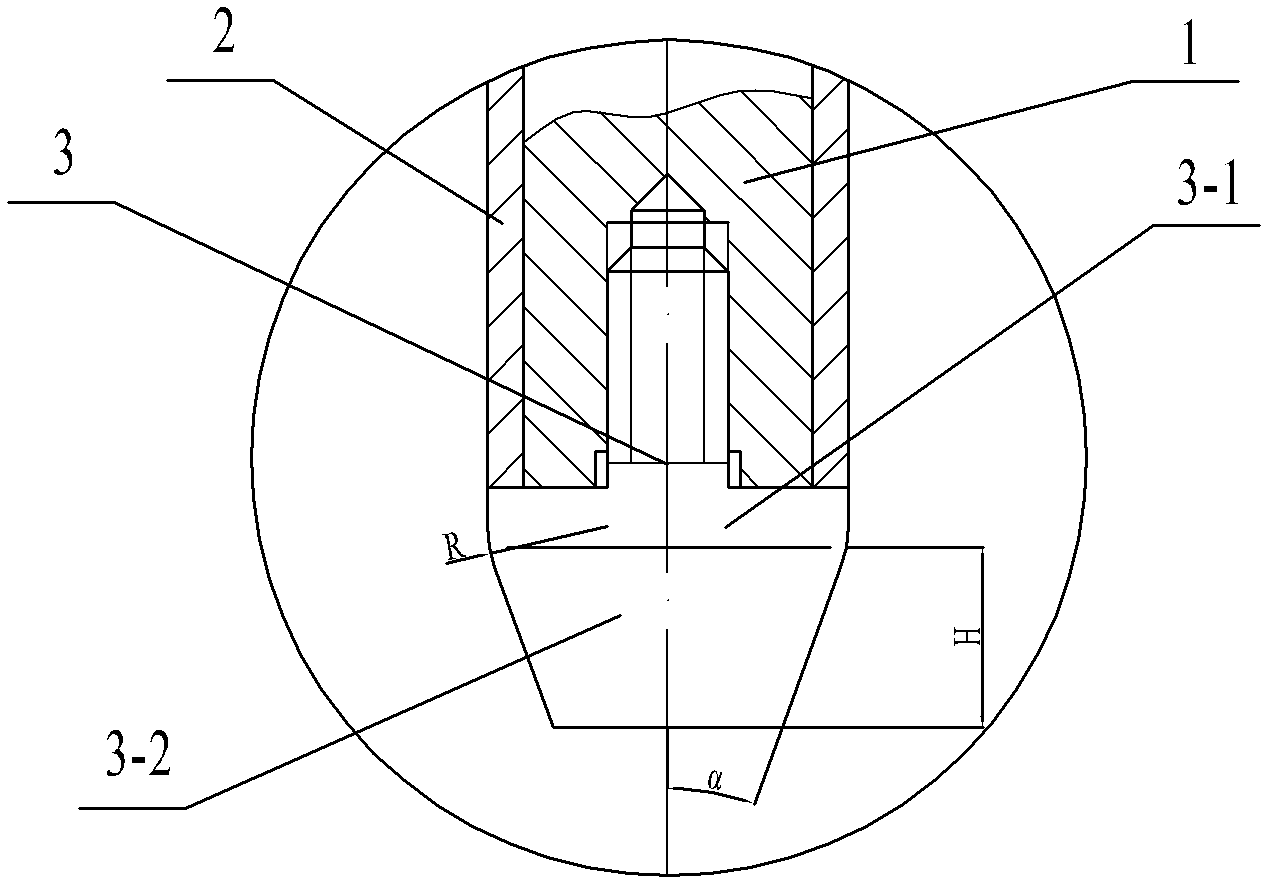

[0007] Embodiment 1: Combining figure 1 and figure 2 Describing this embodiment, the extrusion needle for producing non-lubricated hot-extruded seamless pipes in this embodiment includes a needle core 1, a cemented carbide outer casing 2 and a screw 3, and the needle core 1 is arranged in the cemented carbide outer casing 2, The lower end of the needle core 1 is flush with the lower end of the cemented carbide casing 2 , and the needle core 1 is encapsulated in the cemented carbide casing 2 by screws 3 .

specific Embodiment approach 2

[0008] Specific implementation mode 2: Combining figure 1 and figure 2 The present embodiment will be described. The needle core 1 and the screw 3 of the present embodiment are made of H13 material. This arrangement increases the strength of the extrusion needle. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation three: combination figure 1 and figure 2 Describing this embodiment, the screw head of the screw 3 in this embodiment is integrally formed by a cylindrical portion 3-1 and a circular frustum portion 3-2 from top to bottom, the busbar of the frustum portion 3-2 and the frustum portion 3-2 The included angle α of the axes is 20°. This setting is easy to use. Other compositions and connection relationships are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com