Paulownia flower extractive feed additives

A feed additive, the technology of paulownia flower, applied in animal feed, animal feed, application, etc., can solve the problems of application limitation of paulownia flower, increase of manpower input, uneven mixing, etc., and achieve prevention of animal digestive tract diseases, no antibiotic residue, The effect of improving production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

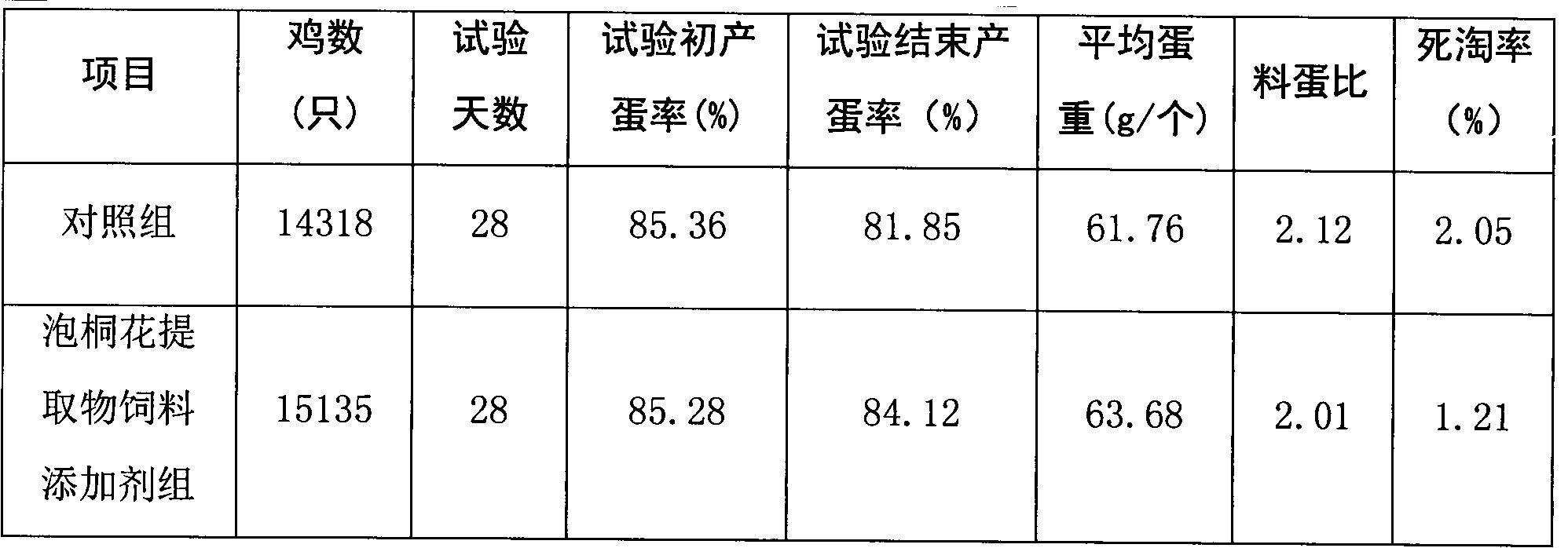

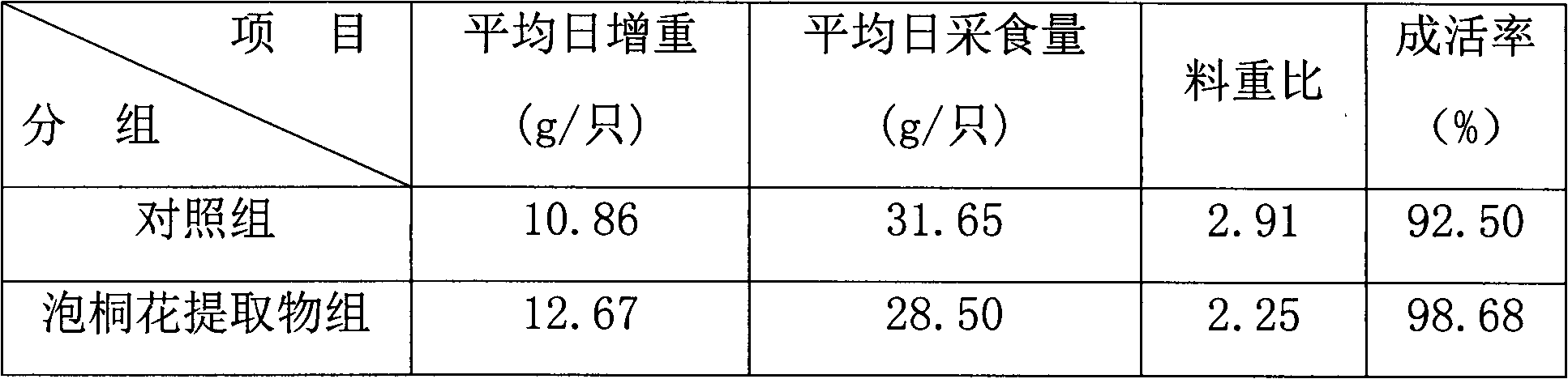

Examples

Embodiment 1

[0013] Take 100kg of paulownia flowers, crush them into coarse powder of 5-20 meshes, then add 1000kg of water to soak for 0.5 hours, heat and extract at 100°C, and extract for 1 hour, filter the medicinal liquid to obtain the first filtrate and the first filter residue Add 600kg of water and mix with the first filter residue to carry out the second extraction, the temperature is 100°C, and the extraction time is 1 hour to obtain the second filtrate and the second filter residue, merge the first filtrate and the second filtrate, and use a decompression concentration tank The medicinal solution is concentrated to obtain the paulownia flower extract feed additive extract with a relative density of 1.20. Then the extract was spray-dried in a spray drying tower, the tower inlet air temperature was 170°C, the outlet air temperature was 80°C, and the inlet air pressure was 40Mpa to obtain the Paulownia flower extract dry powder with a moisture content of 2.38%. The dry powder of the...

Embodiment 2

[0025] Take 100kg of paulownia flowers, crush them into coarse powder of 5-20 meshes, add 600kg of water to soak for 1 hour, heat and extract at a temperature of 100°C, and extract for 2 hours, filter the medicinal liquid to obtain the first filtrate and the first filter residue Add 400kg of water and mix with the first filter residue to carry out the second extraction, the temperature is 100°C, and the extraction time is 1 hour to obtain the second filtrate and the second filter residue, merge the first filtrate and the second filtrate, and use a decompression concentration tank The medicinal solution is concentrated to obtain the paulownia flower extract extract with a relative density of 1.15. The extract is then spray-dried in a spray drying tower, with an inlet air temperature of 180° C., an outlet air temperature of 85° C., and an inlet air pressure of 40 MPa to obtain a dry powder of Paulownia flower extract with a moisture content of 2.52%. Then, the dry powder of the ...

Embodiment 3

[0033] Take 100kg of paulownia flowers, crush them into coarse powder of 5-20 meshes, then add 800kg of water to soak for 0.5 hours, heat and extract at 100°C for 2 hours, filter the medicinal liquid to obtain the first filtrate and the first filter residue After adding 500kg of water and mixing with the first filter residue for the second extraction, the temperature is 100° C., and the extraction time is 1 hour to obtain the second filtrate and the second filter residue, merge the first filtrate and the second filtrate, and use a decompression concentration tank The medicinal solution is concentrated to obtain the paulownia flower extract feed additive extract with a relative density of 1.10. The extract is then spray-dried in a spray drying tower, with an inlet air temperature of 190° C., an outlet air temperature of 90° C., and an inlet air pressure of 40 MPa to obtain a dry powder of Paulownia flower extract with a moisture content of 2.45%. The dry powder of the paulownia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com