Manufacturing method of circuit board with combination of flexible circuit board and hard circuit board

A combination of soft and hard, and a manufacturing method, which is applied in the direction of assembling printed circuits with electrical components, and can solve problems such as difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The fabrication method of the rigid-flex circuit board provided by the technical solution will be further described below in conjunction with the accompanying drawings and embodiments.

[0054] The manufacturing method of the soft-rigid circuit board provided by the technical solution includes the following steps:

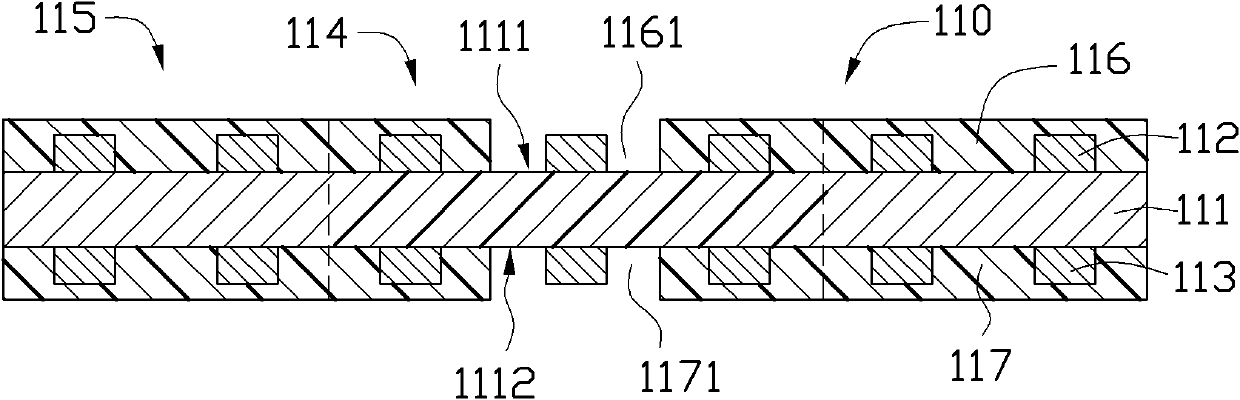

[0055] For a first step, see figure 1 , providing a flexible circuit board 110 .

[0056] The flexible circuit board 110 is a circuit board fabricated with conductive circuits. The flexible circuit board 110 can be a single-sided circuit board or a double-sided circuit board. In this embodiment, the flexible printed circuit board 110 is taken as an example for illustration. The flexible circuit board 110 includes a first insulating layer 111 , a first conductive circuit 112 , a second conductive circuit 113 , a first covering film 116 and a second covering film 117 . The first insulating layer 111 includes an opposite first surface 1111 and a second surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com