A controller for double heating tubes

A controller and heating tube technology, used in fluid heaters, lighting and heating equipment, ohmic resistance heating components, etc., can solve problems such as heating tubes not heating, damage to the user's electrical environment, and water heaters not working.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

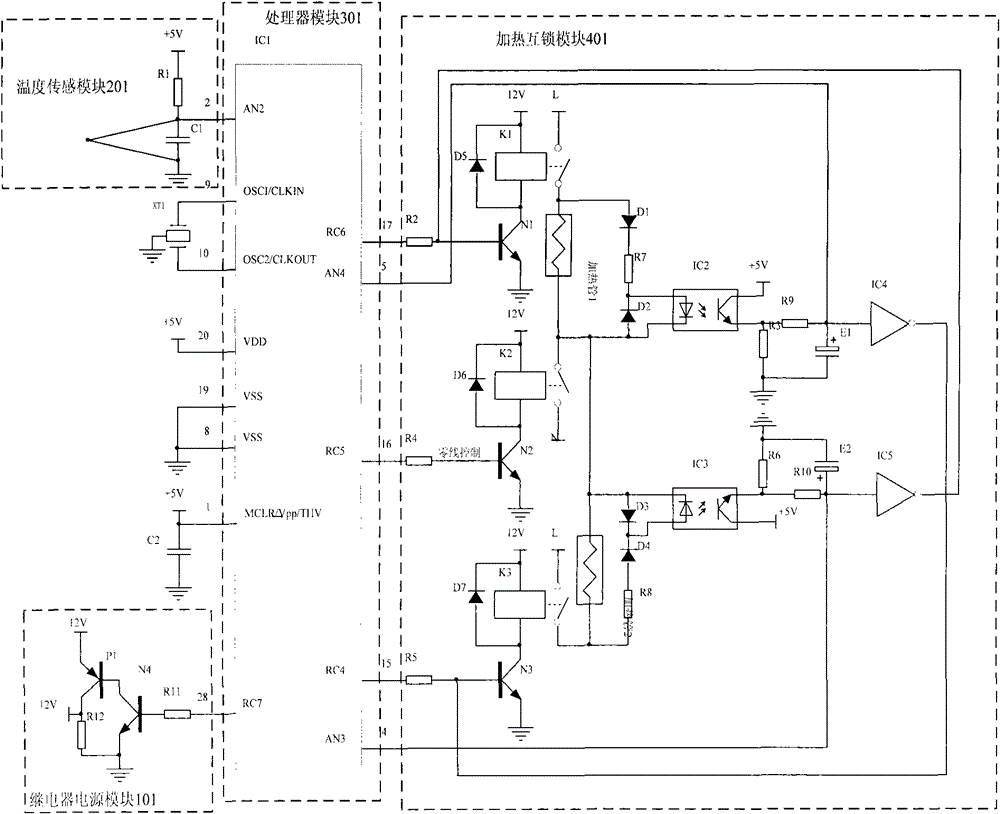

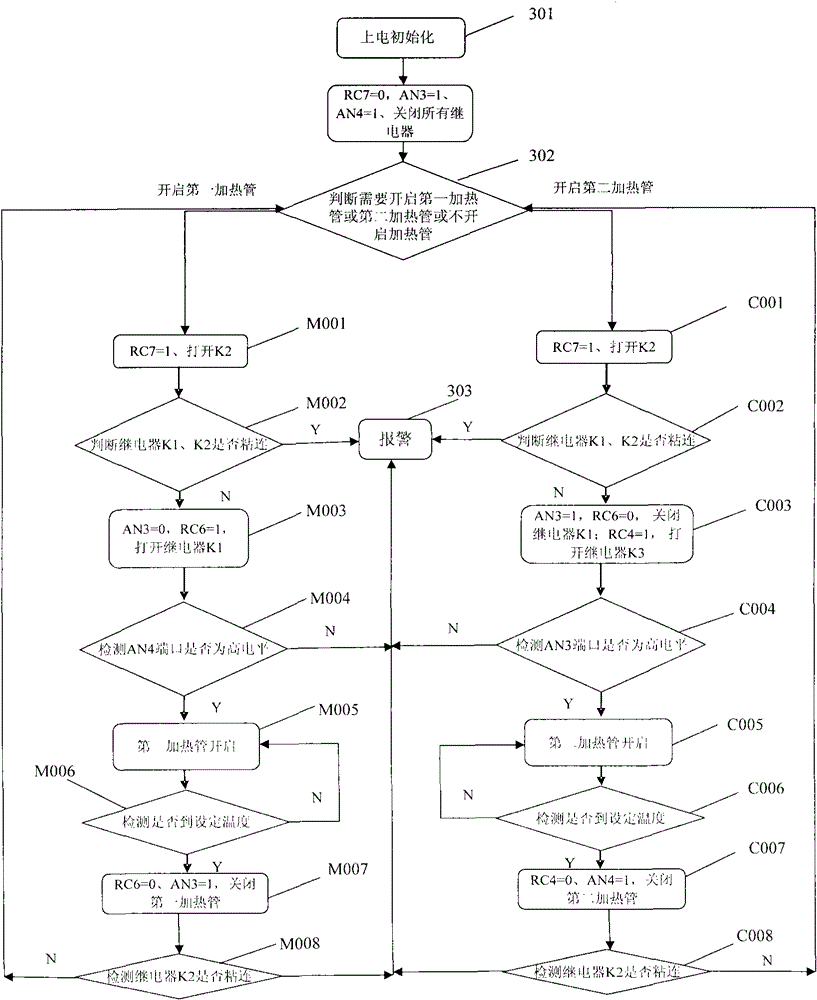

[0024] figure 1 It is a schematic circuit diagram of the present invention, including a relay power supply module 101 , a temperature sensing module 201 , a processing module 301 , and a heating interlock module 401 .

[0025] The relay power supply module 101 is connected to the RC7 port of the processing module 301 for receiving the control signal of the processing module 301 to disconnect or close the 12V control voltage to the heating interlock module 401 .

[0026] The temperature sensing module 201 is connected to the AN2 port of the processing module 301 for detecting the temperature of the water in the inner tank of the water heater and sending a temperature signal to the processing module 301 .

[0027] The processing module 301 is a single-chip microcomputer, which is used to control the power supply of the relay power supply module 101, and control the interlock and adhesion detection of the heating interlock module 401 for power supply to the two heating tubes of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com