Temperature sensor circuit

A temperature sensor and circuit technology, applied in thermometers, instruments, scientific instruments, etc., can solve the problems of high-precision ADC area and power consumption, low voltage, high ADC accuracy requirements, etc., to achieve the effect of easy control and realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

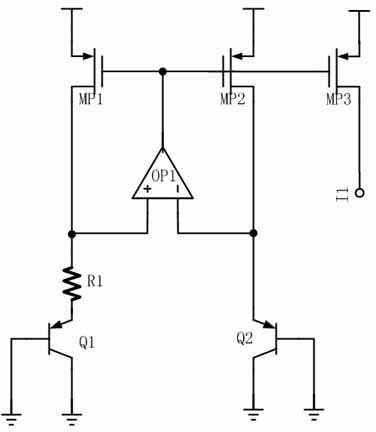

[0041] According to Figure 1 ~ Figure 12 , Specifically describe the preferred embodiment of the present invention:

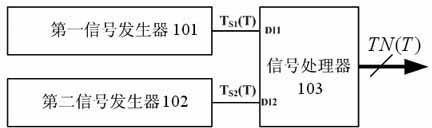

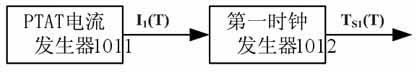

[0042] Such as figure 1 Shown is a schematic structural diagram of a temperature sensor circuit provided by the present invention. The temperature sensor circuit includes a first signal generator 101, a second signal generator 102, and a signal processor 103. The output terminals of the first signal generator 101 and the second signal generator 102 are connected to the input terminal of the signal processor 103.

[0043] The first signal generator 101 generates a temperature-related signal S 1 , The second signal generator 102 generates a signal S that is related to temperature and has a definite functional relationship with the signal generated by the first signal generator 101 2 ; The signal generated by the first signal generator 101 and the signal generated by the second signal generator 102 are input to the signal processor 103 for processing, and the signal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com