Liquid-permeable nonwoven fibrous fabric

A non-woven fabric and liquid-permeable technology, applied in the field of liquid-permeable fiber non-woven fabrics, can solve the problem of easy to stay on the bottom surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

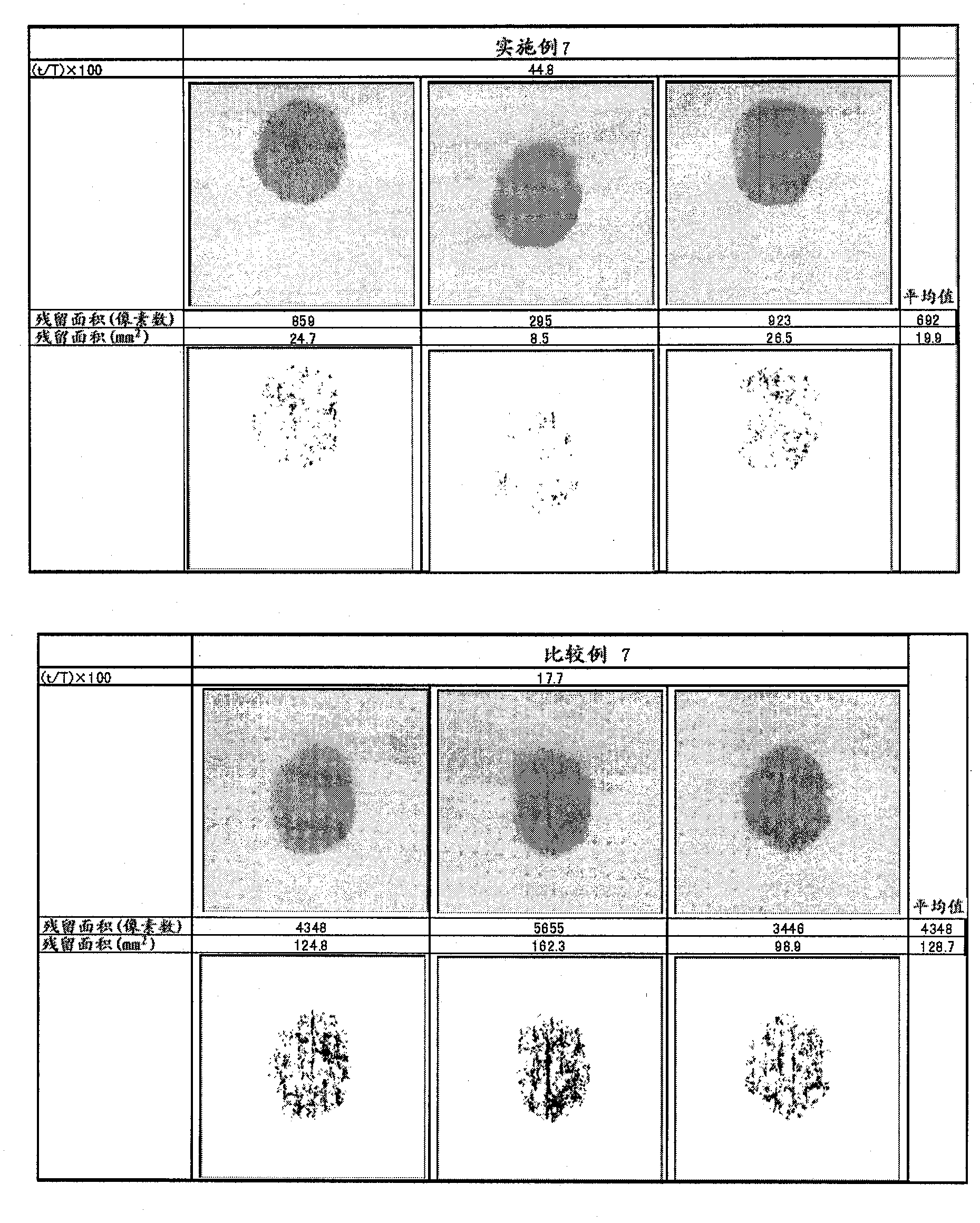

Examples

Embodiment 1 to 10

[0086] 1. As short fibers for obtaining the fiber nonwoven fabrics of Examples, first and second composite short fibers in which the core component is polyester resin and the sheath component is polyethylene resin are mixed. The fineness of the first composite staple fibers was 2.2 dtex, the fiber length was 45 mm, and the mass per square meter of the entire staple fibers was 80% by mass. The fineness of the second composite short fibers was 2.6 dtex, the fiber length was 38 mm, and the mass per square meter of the entire short fibers was 20% by mass. The first and second short fibers after mixing are processed by drum carding machine to obtain a quality of 15g / m 2 , 25g / m 2 、35g / m 2 、40g / m 2 fiber web.

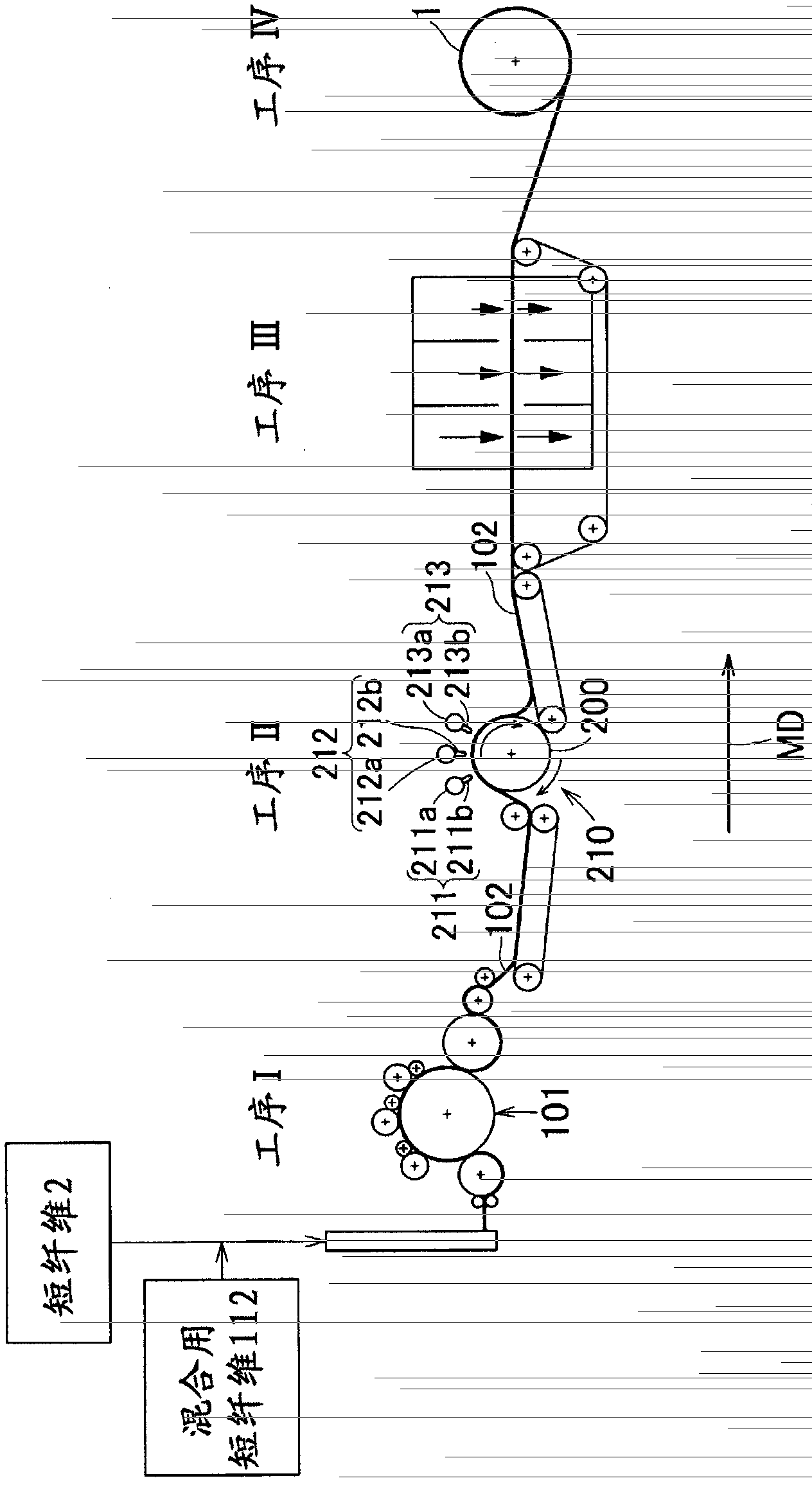

[0087] 2. in figure 2 These fiber webs were processed in the process. Set as follows figure 2 Conditions of the first, second and third nozzle assemblies in process II.

[0088] (first and second nozzle assemblies)

[0089] Air temperature in nozzle header: 200°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com