Preparation method of metamaterial and metamaterial

A metamaterial and functional board technology, applied in the field of metamaterials, can solve the problems of limited selectivity and insufficient flexibility affecting the permittivity and permeability, permittivity and permeability, and achieve good uniformity , a wide range of material selectivity, and the effect of expanding the range of functional applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Taking the metamaterial with the dielectric substrate of the polymer material as an example, although the polymer material has good mechanical properties, the general dielectric constant of the polymer material is low. In order to obtain a higher dielectric constant, it is very convenient to adopt the method of the present invention Calcium copper titanate (CaCu) with high dielectric constant 3 Ti 4 o 12 ) to prepare metamaterials by sol-gel process, the specific preparation process is as follows:

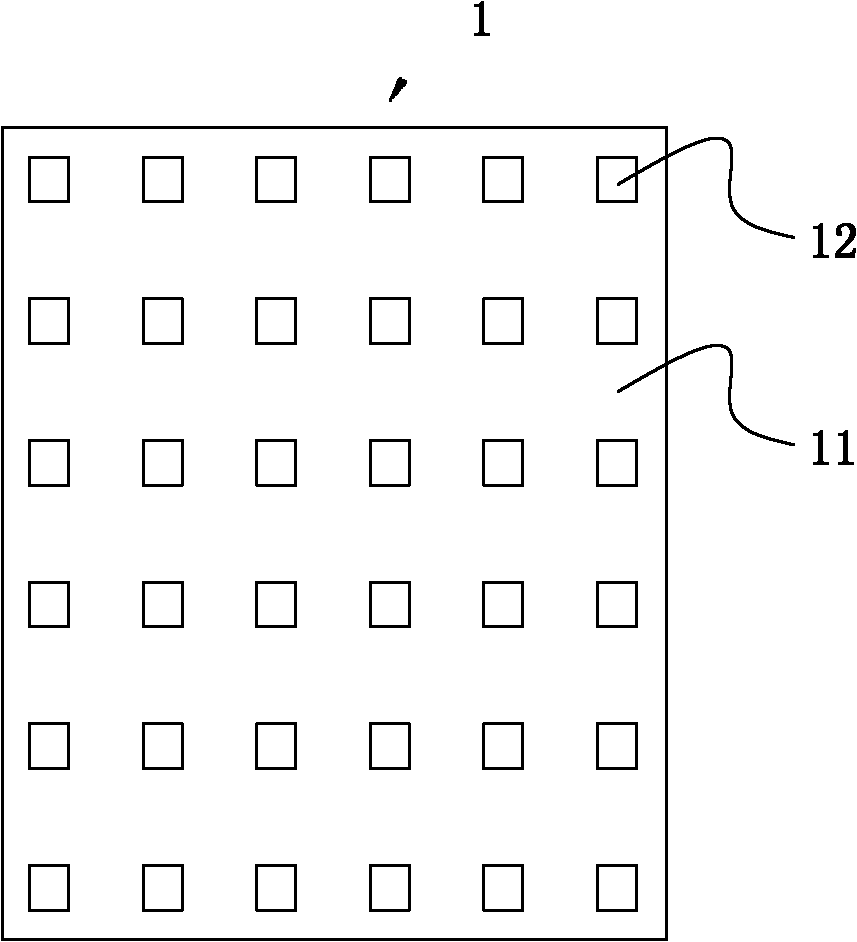

[0026] a. Multiple artificial microstructures are arrayed on the dielectric substrate of the metamaterial functional board to form a metamaterial functional board;

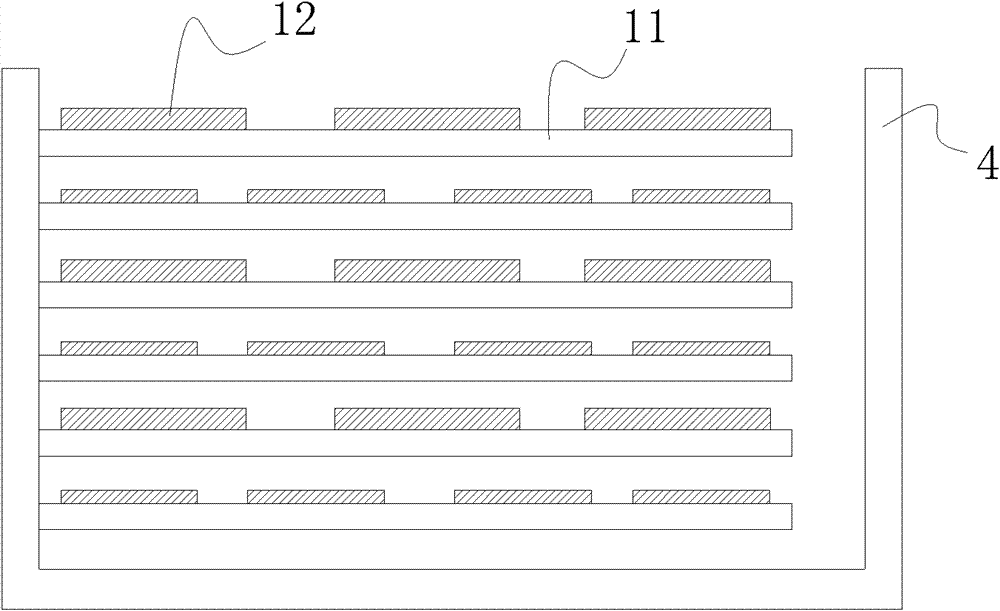

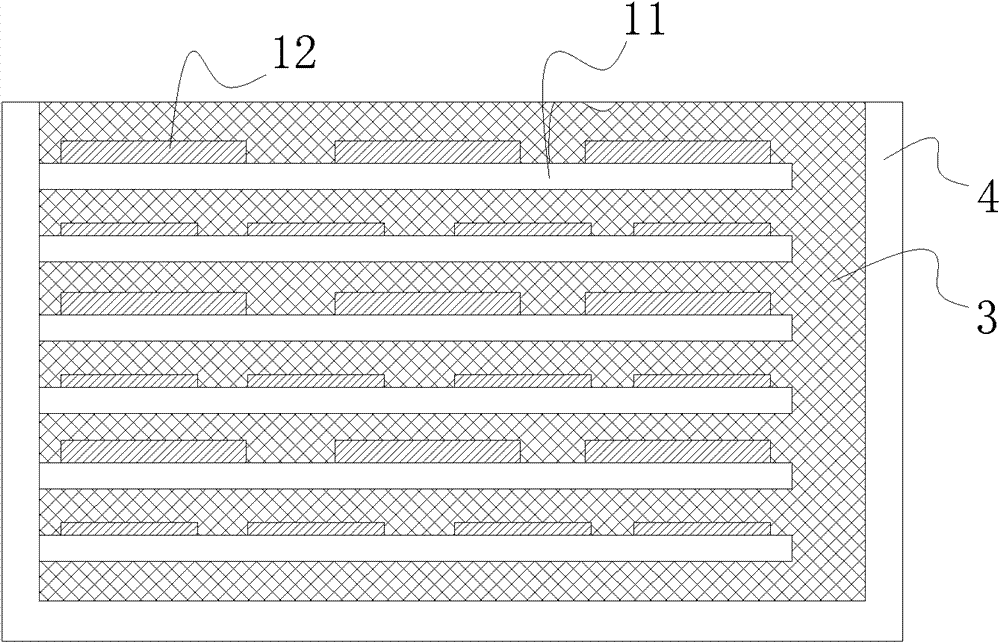

[0027] b. Fix multiple metamaterial functional boards in the mold according to the predetermined interval;

[0028] c. Accurately weigh calcium nitrate (concentration 99%), copper nitrate (concentration 99.5%), butyl titanate (analytical pure) according to molar ratio Ca: Cu: Ti is the ratio of 1: 3: 4 for la...

Embodiment 2

[0035] Sometimes, in order to make the metamaterial obtain higher magnetic permeability, it can be realized very conveniently after adopting the method of the present invention, with cobalt-nickel ferrite (Co 1-x Ni x Fe 2 o 4 ) as an example, the specific process of preparing metamaterials by sol-gel process is as follows:

[0036] a. Multiple artificial microstructures are arrayed on the dielectric substrate of the metamaterial functional board to form a metamaterial functional board;

[0037] b. Fix multiple metamaterial functional boards in the mold according to the predetermined interval;

[0038] c. First weigh a certain amount of citric acid and add it to distilled water and heat it in a constant temperature water bath at 80°C. After the citric acid is completely dissolved, add ferric nitrate, cobalt nitrate and nickel nitrate in turn, wherein the molar ratio of cobalt-nickel ions is 0.5:0.5, the molar ratio of ferric nitrate and citric acid is 1:1;

[0039] d. Sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com