Solar cell and method for fabricating the same

A solar cell and manufacturing method technology, which is applied in the directions of manufacturing tools, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of increasing the angle of the top of the pyramid structure, increasing the reflectivity, and decreasing the photocurrent, and achieves a simple manufacturing method. , Improve coating problems, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1~3

[0090] After the pyramid structure is formed on the silicon substrate, the silicon substrate is then subjected to a laser treatment process. The parameters of the laser treatment process are as follows:

[0091] Laser wavelength: 532nm

[0092] Focus height: -14.6mm

[0093] Beam size: 50 um

[0094] Energy density: 2J / m 2 (Experimental Example 1), 2.25J / m 2 (Experimental Example 2), 2.5J / m 2 (Experimental example 3)

[0095] Stage speed: 100_mm / sec

PUM

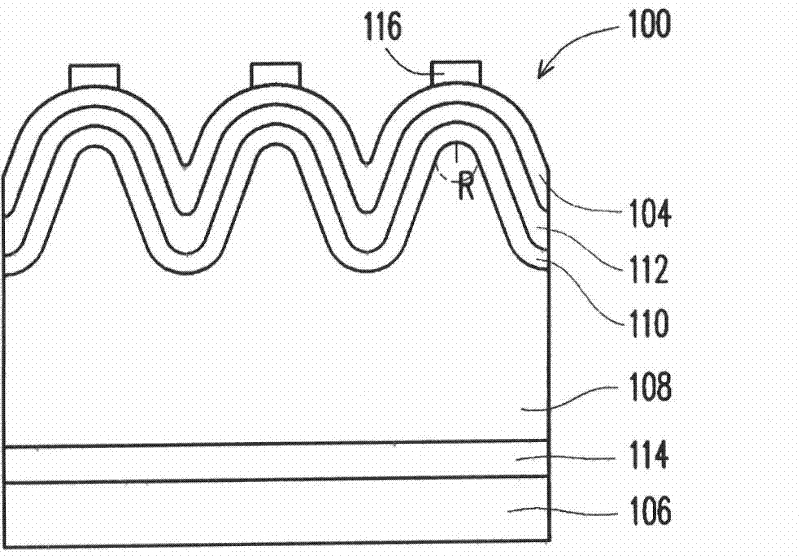

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com