Polymer actuator and valve using the same

An actuator and polymer technology, applied in the field of polymer actuators, can solve problems such as complex internal structure, deterioration of efficiency, wear of sealing parts and sliding parts, and achieve high sealing performance, ensure sealing performance, and prevent sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

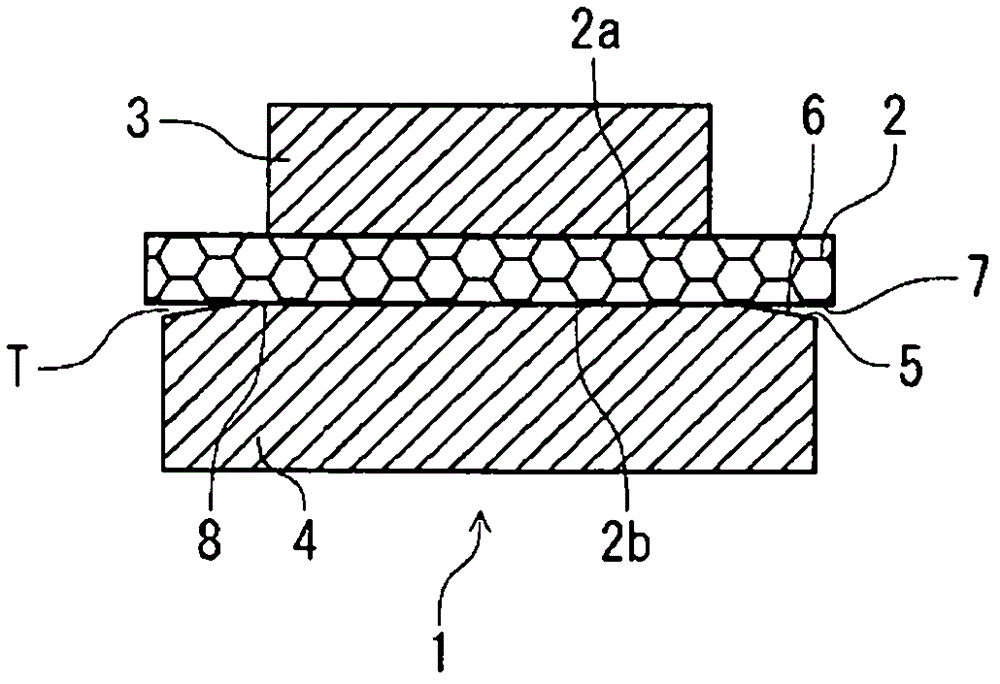

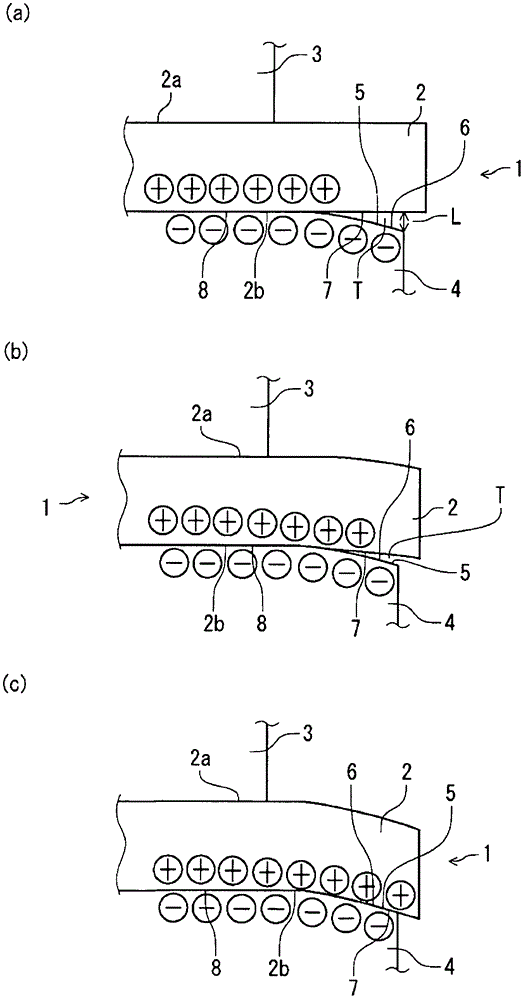

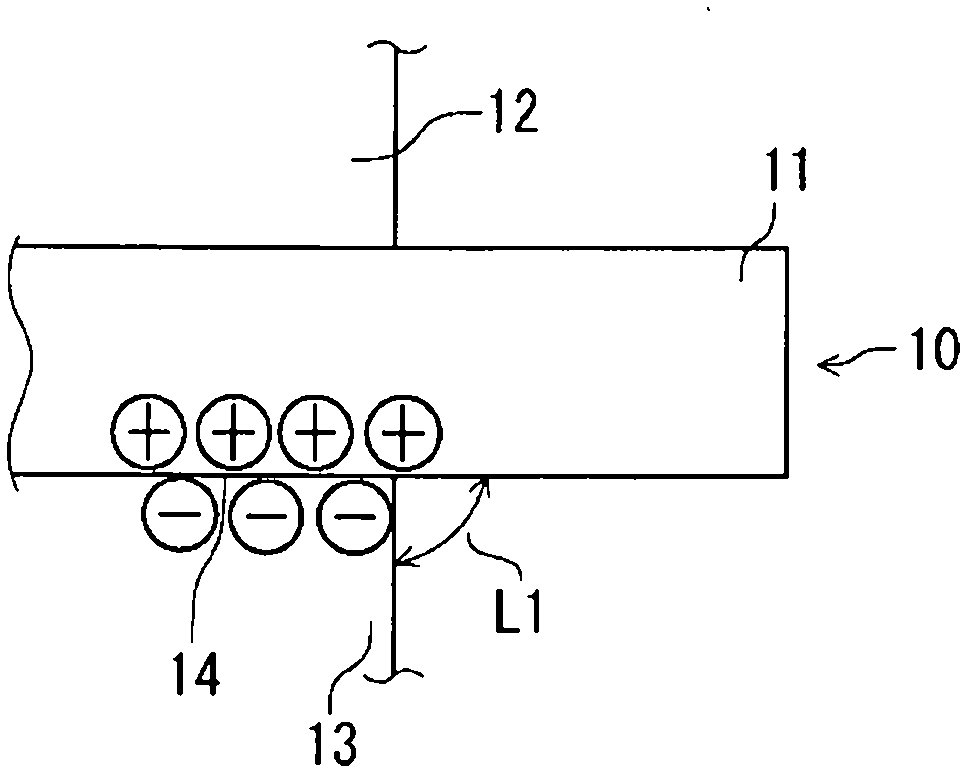

[0206] Will figure 1 The shown actuator body 1 with the fixed electrode 4 with the arcuate surface 6 is formed as Figure 16 The actuator body 1 was used as a test product A, and the displacement of the driving body 2 was measured by the above-mentioned displacement measuring device 100 . On the other hand, as a comparison of the actuator main body 1, the image 3 The illustrated actuator part 10 is formed as Figure 17 The dimensions shown were used as a comparative product a, and the displacement amount of the driving body portion 11 was measured in the same manner. Figure 16 The driver 2 in Test Sample A is composed of ester-based polyurethane to which 0.5 wt % of tetrabutylammonium chloride is added, and is formed to have a diameter of 20 mm and a thickness of 0.1 mm. On the other hand, an inclined surface 6 is formed on the negative side fixed electrode 4 , and the entire positive side fixed electrode 3 is fastened to the driver 2 .

[0207] The state of voltage appl...

Embodiment 2

[0210] will be Figure 7 The shown actuator body 40 with flexible electrodes 41, 42 formed on the driving body 2 with the arcuate surface 6 is formed as Figure 20 , and use it as test item B. The driver 2 in the test sample B is composed of ester-based polyurethane to which 0.5 wt % of tetrabutylammonium chloride is added, and is formed to have a diameter of 20 mm and a thickness of 0.1 mm. On the driver 2, a gold thin film was formed on the negative side with a diameter of 16 mm or less by sputtering, and a gold thin film was formed on the entire surface of the positive side by sputtering. On the other hand, the above-mentioned arcuate surface 6 is formed as an inclined surface on the negative side fixed electrode 4 , and the entire positive side fixed electrode 3 is fastened to the driver 2 .

[0211] Figure 21 In, means relative to image 3 The actuator part of is used as the comparison product b of the actuator part 16 formed with the flexible electrode parts 14 and ...

Embodiment 3

[0220] Next, put Figure 7 The actuator body 40 is formed as Figure 28 The size of the test product E is used as the test product E, and the applied voltage is stepped up by 0.1kV each time, so that the deformed part of the driving body 2 is bent and displaced until it meets the arc surface 6 of the fixed electrode 4 After the contact, the applied voltage was lowered stepwise by 0.1 kV each time. The change in the voltage at this time and the change in the displacement of the driving body are represented by Figure 29 middle.

[0221] according to Figure 29 As a result of the measurement, even at the same applied voltage, the amount of displacement may be different when the applied voltage is raised and lowered, and the locus of the change in the amount of displacement is different when the voltage rises and falls. That is, when the applied voltage was raised to 0.7kV, the displacement increased, but when the applied voltage was lowered to 0.7kV, the shape did not return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com