Multilayer inductor

An inductor and multilayer technology, applied in the field of multilayer inductors, can solve problems such as poor DC superposition characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

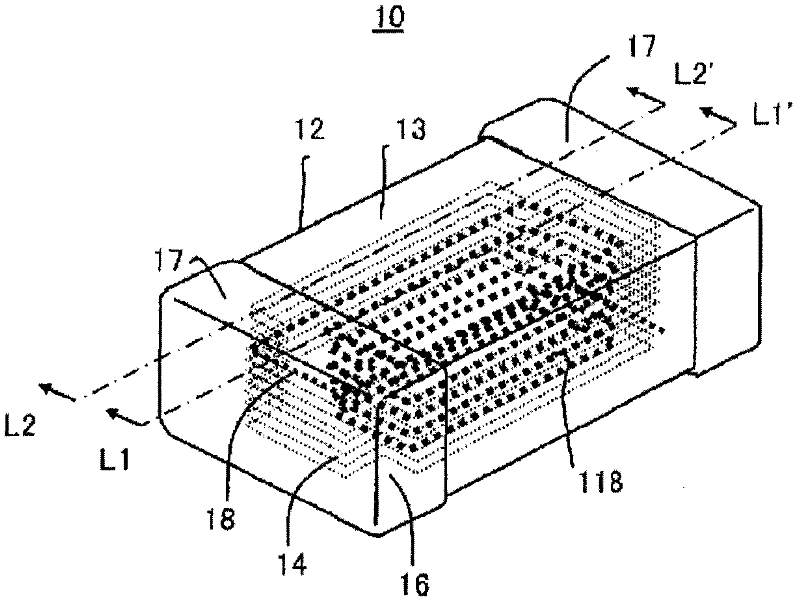

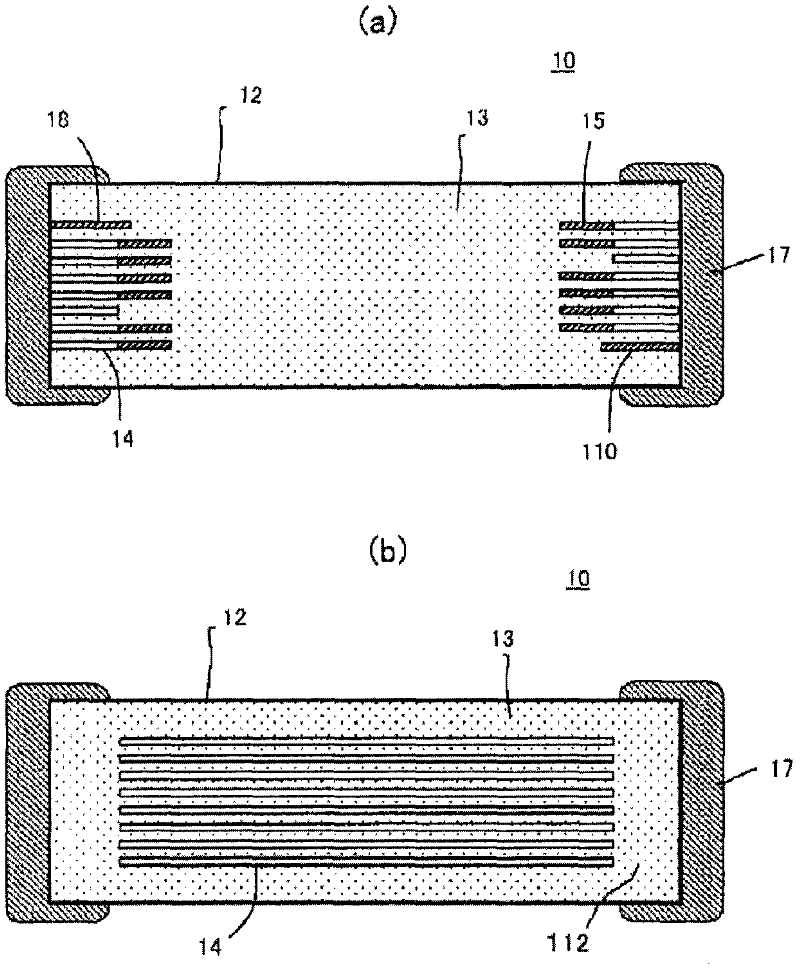

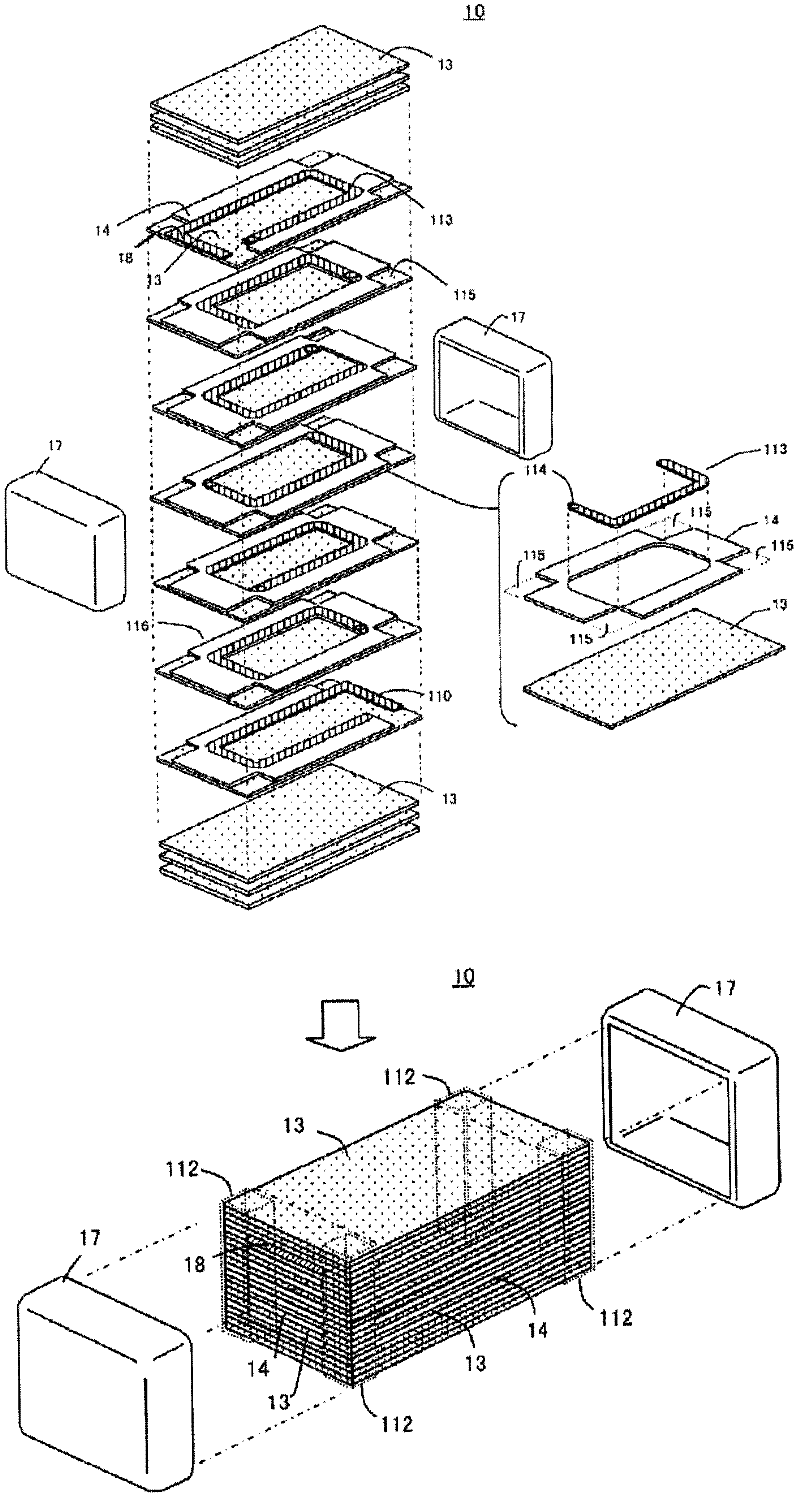

[0058] The first embodiment of the present invention is shown in Figure 1~3 . figure 1 is a stereogram, figure 2 is a cross-sectional view, figure 2 (a) is figure 1 Sectional view of L1-L1′, figure 2 (b) is figure 1 Sectional view of L2-L2′. image 3 yes figure 1 Elementary configuration diagram of the laminate chip shown.

[0059] The first embodiment of the multilayer inductor of the present invention is as follows figure 1 , image 3 As shown, a rectangular parallelepiped-shaped laminate chip 12 and a pair of external electrodes 17 formed on the end faces of the laminate chip are included.

[0060] Specifically, the laminated body chip 12 includes a plurality of magnet layers 13 having a rectangular planar shape and being laminated in the thickness direction, and a plurality of coil patterns 113 arranged between adjacent magnet layers. The coil patterns 113 are connected to each other to form a helical coil 118 . Further, the coil conductor 15 is formed ...

no. 2 approach

[0063] The second embodiment of the present invention is shown in Figure 4 .

[0064] A second embodiment of the multilayer inductor of the present invention is as Figure 4 As shown, a rectangular parallelepiped-shaped laminate chip 12 and a pair of external electrodes 17 formed on the end faces of the laminate chip are included.

[0065] Specifically, the laminated body chip 12 has a plurality of magnet layers 13 having a rectangular planar shape and are laminated in the thickness direction, and a plurality of coil patterns 113 respectively arranged between adjacent magnet layers. The coil patterns 113 are connected to each other to form a helical coil. Moreover, the lead-out part 18,110 which reaches the edge part of a magnetic body layer is connected to the start end and the terminal end of this coil, and the coil conductor is formed. Then, the non-magnetic layer 14 is arranged in the area outside the helical coil between layers of the adjacent magnetic layers 13 in th...

Embodiment 1

[0083] First, ethyl cellulose and terpineol were added to the FeO 2 , CuO, ZnO, NiO as the main material and the Ni-Zn-Cu series ferrite fine powder after calcining and crushing are kneaded to make a slurry. The slurry is applied to a certain thickness with a doctor blade, and the dried slurry is cut into a specific size for printing to form a magnet sheet. Through-holes are formed at specific positions on the magnet sheet by methods such as die-drilling or laser machining perforation. The silver paste was then printed onto the magnet sheet using a screen having the shape of a part of the coil pattern and dried. Non-magnetic slurry is to add ethyl cellulose, terpineol to FeO 2 , CuO, ZnO as the main material and made by mixing and kneading Zn-Cu ferrite fine powder after calcining and crushing. Screen printing was performed by positioning the non-magnetic paste to be printed on a specific position outside the coil pattern. At this time, the printed pattern shape of the non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com