Laser treatment device and container-producing device

A laser processing device, laser beam technology, applied in the direction of containers, household containers, rigid containers, etc., can solve the problems of insufficient prevention of resin hair, high efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] A laser processing apparatus (container manufacturing apparatus) according to an embodiment of the present invention will be described in detail below with reference to the drawings. In addition, in this specification and drawings, the overlapping description is abbreviate|omitted by attaching the same code|symbol to the component which has substantially the same functional structure.

[0067] (first embodiment)

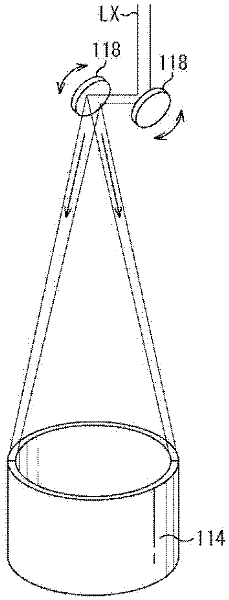

[0068] First, the first embodiment will be described. image 3 It is a diagram showing the laser processing apparatus (container manufacturing apparatus) according to the first embodiment of the present invention, and is a perspective view seen from obliquely above the cup-shaped body 14 as a workpiece to be processed. and, Figure 4A It is a plan view viewed from the upper side of the cup-shaped body 14; Figure 4B In order to enlarge the top view of the irradiated part of the upper edge end 14a of the cup-shaped body 14 to which the laser beams LA and LB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com