Preparation method for composite electrode material composed of graphite and manganese dioxide

A technology of manganese dioxide and composite materials, which is applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of reduced capacitance performance, loss of specific surface area, and agglomeration of graphene materials, and achieves reduced agglomeration, excellent capacitance performance, and a simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

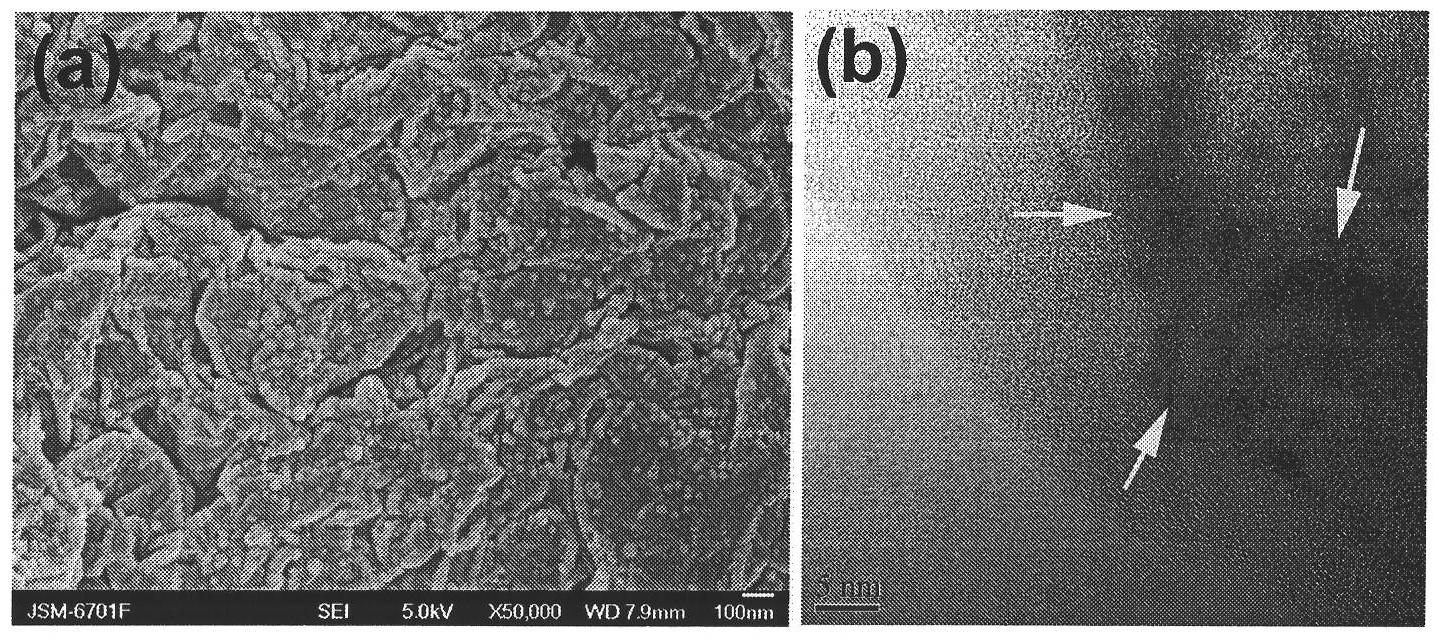

[0026] (1) Preparation of graphene oxide-manganese dioxide composite material:

[0027] 10mL 4mg·mL -1 Graphene oxide and 2mL at a concentration of 0.05mol mL -1 KMnO 4 The solution was mixed and sonicated for 30 minutes. Transfer the above mixture to a round bottom flask, add 2mL of 0.05mol·mL -1 The citric acid solution was stirred at room temperature for 15 minutes, and finally the resulting mixed solution was heated to reflux at 80° C. for 7 hours to obtain a black graphene oxide-manganese dioxide composite colloidal solution.

[0028] (2) In situ reduction of graphene oxide-manganese dioxide composites:

[0029] Add 80mL of deionized water to the obtained graphene oxide-manganese dioxide composite colloidal solution, ultrasonic treatment for 30 minutes, then add 2mL of hydrazine hydrate (80wt.%), and heat to reflux at 100°C for 24 hours, use a large amount of ethanol and Washing with deionized water and suction filtration, drying at 60°C in a vacuum oven to obtain a ...

Embodiment 2

[0036] (1) Preparation of graphene oxide-manganese dioxide composite material:

[0037] 10mL 4mg·mL -1 Graphene oxide and 2mL at a concentration of 0.1mol mL -1 KMnO 4 The solution was mixed and sonicated for 30 minutes. Transfer the above mixed solution to a round bottom flask, add 2mL concentration of 0.1mol mL -1 The citric acid solution was stirred at room temperature for 15 minutes, and finally the resulting mixed solution was heated to reflux at 80° C. for 7 hours to obtain a black graphene oxide-manganese dioxide composite colloidal solution.

[0038] (2) In situ reduction of graphene oxide-manganese dioxide composites:

[0039] Add 80mL of deionized water to the obtained graphene oxide-manganese dioxide composite colloidal solution, ultrasonic treatment for 30 minutes, then add 2mL of hydrazine hydrate (80wt.%), and heat to reflux at 100°C for 24 hours, use a large amount of ethanol and Wash with deionized water, filter with suction, and dry in a vacuum oven at 60...

Embodiment 3

[0042] (1) Preparation of graphene oxide-manganese dioxide composite material:

[0043] 10mL 4mg·mL -1 Graphene oxide and 2mL at a concentration of 0.05mol mL -1 KMnO 4 The solution was mixed and sonicated for 30 minutes. Transfer the above mixture to a round bottom flask, add 2mL of 0.05mol·mL -1 The citric acid solution was stirred at room temperature for 15 minutes, and finally the resulting mixed solution was heated and refluxed at 80°C for 7 hours to obtain a black graphene oxide-manganese dioxide composite colloidal solution, which was filtered and washed with a large amount of ethanol and deionized Wash with water, filter with suction, and dry in a vacuum oven at 60°C to obtain graphene oxide-manganese dioxide composite material powder.

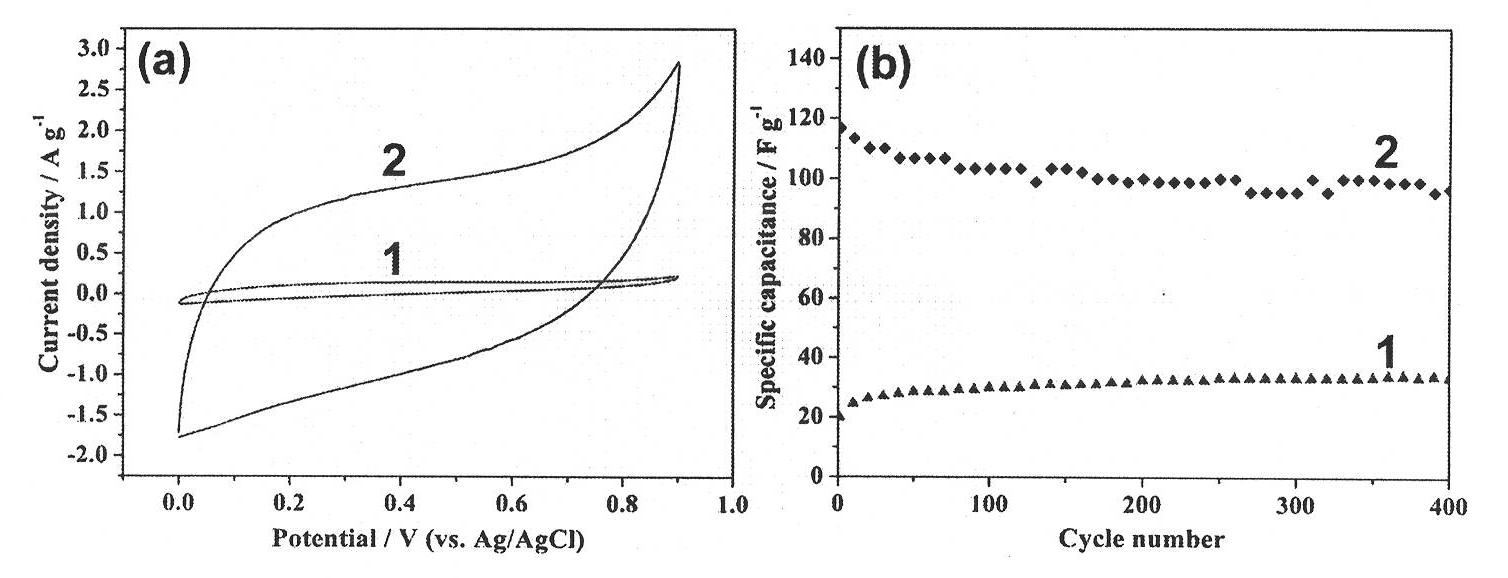

[0044] (2) The obtained graphene oxide-manganese dioxide composite material powder is electrochemically tested, and the steps are the same as in Example 1. The results showed that at 0.5A·g -1 The specific capacitance of the grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com