Appearance detection method of quasi-monocrystalline silicon wafer

An appearance inspection, quasi-single crystal technology, applied in the field of inspection, to achieve the effect of improving the accuracy and being easy to popularize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The appearance inspection method of quasi-single crystal silicon wafer is different in that it includes the following steps:

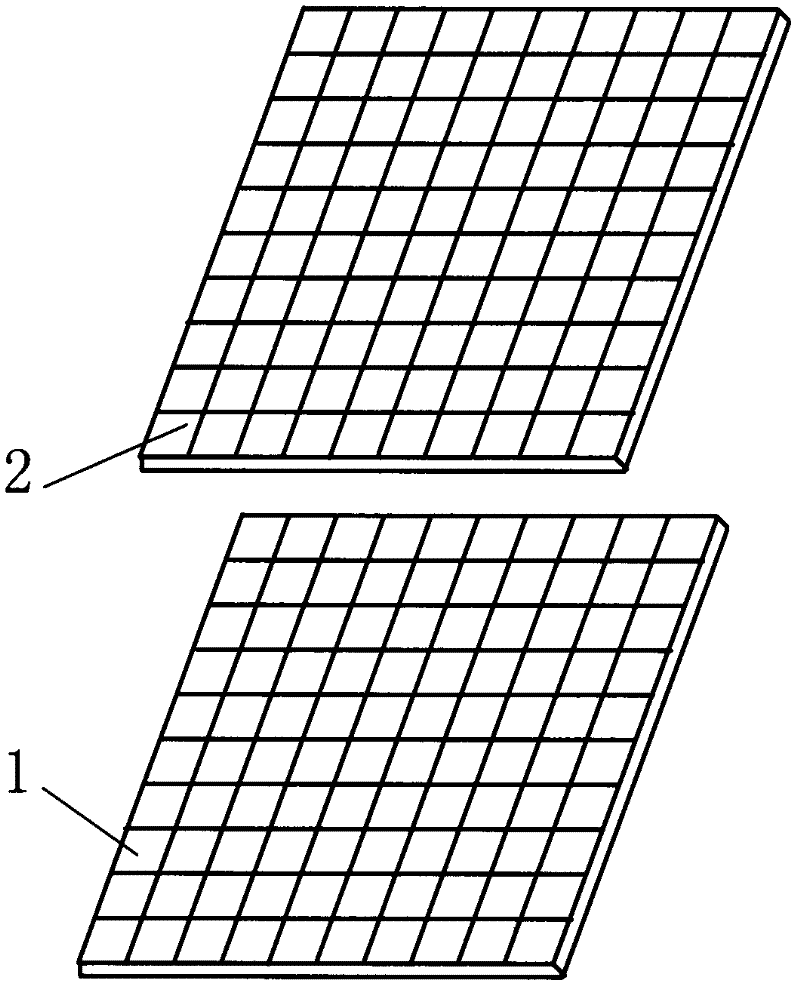

[0015] Firstly, the surface area of the quasi-single crystal silicon wafer is divided into n×n grids, so that the area of each grid occupies 1 / (n×n) of the area of the entire quasi-single crystal silicon wafer 1 . Specifically, taking n=10 as an example, each grid represents 1 / 100 of the surface area of a quasi-single crystal silicon wafer, that is, figure 1 shown.

[0016] Next, for the convenience of subsequent detection, the n×n array is fabricated on a transparent substrate through grid lines to form a two-dimensional grid scale 2 . Specifically, the manufacturing method of the two-dimensional grid ruler 2 adopted in the present invention is to use a photoplotter to draw at the central position of the film negative in a dark room. Afterwards, the film negatives that have undergone the light painting process are developed and fixed....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com