Roof runoff and diversion catchment

A water collector and runoff technology, which is applied in the field of environmental pollution prevention and control, can solve the problems of increasing the cost of treatment, increasing the difficulty of runoff treatment and utilization, and inconvenience in construction, so as to achieve the effects of avoiding pollution, increasing aesthetics, and reducing construction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

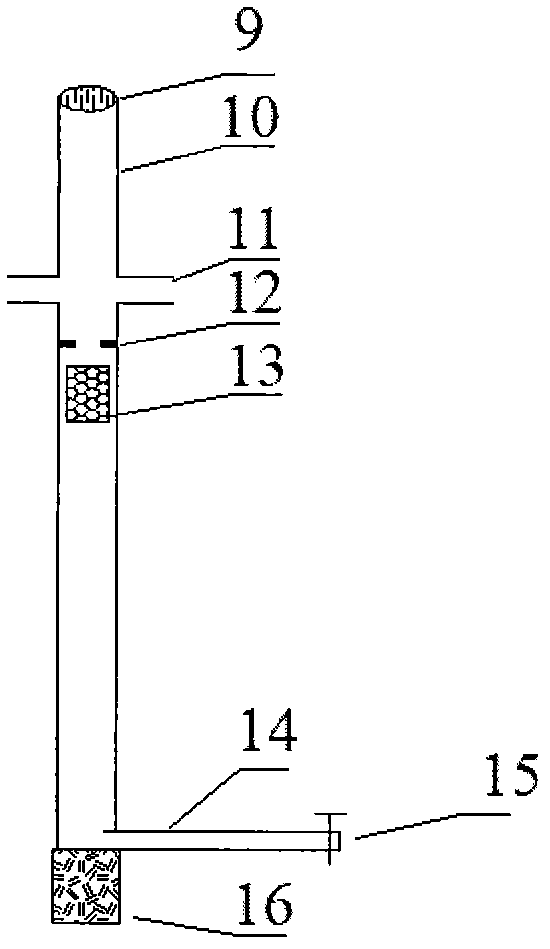

[0027] Such as figure 1 As shown, this embodiment includes: a convex filter screen 1 , a rain downpipe 2 , a hose 3 , a shunt pipe 6 , a water reservoir 5 , an overflow pipe 8 and a first shunt valve 7 . Wherein: the convex filter screen 1 is connected to the rain drop pipe 2, the end of the rain drop pipe 2 is connected to the hose 3, the end of the hose 3 is connected to the shunt pipe 6, and the shunt pipe 6 is located in the center of the water storage 5 and arranged vertically , the overflow pipe 8 is arranged on the outer wall of the upper part of the water storage 5, the first diverter valve 7 is located under one side of the water storage 5, the convex filter screen 1 is located at the water outlet of the eaves gutter, and the water storage 5 Located below the convex filter screen 1, its installation position forms a level difference with the convex filter screen 1. The distribution pipe 5 is composed of a concave filter screen 9 , a vertical pipe 10 , a distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com