Method for preventing double-zero aluminum foil from rebounding after tapping off

A double-zero aluminum foil and post-furnace technology is applied in the field of low-temperature slow cooling outside the aluminum foil furnace to prevent lifting, which can solve the problems of slow cooling, wrinkling, and uneven cooling of the surface of the aluminum coil, and achieve photoelectric cost savings and annealing costs. Decrease, the effect of considerable economic benefits

Active Publication Date: 2013-07-17

JIANGSU DAYA ALUMINUM

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to solve the above-mentioned production problems, the purpose of the present invention is to provide a method for slow cooling outside the furnace after double-zero aluminum foil annealing, which can prevent aluminum coils from being directly exposed to the air due to excessive cooling speed and uneven cooling. Defects such as surface cracking and internal wrinkling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

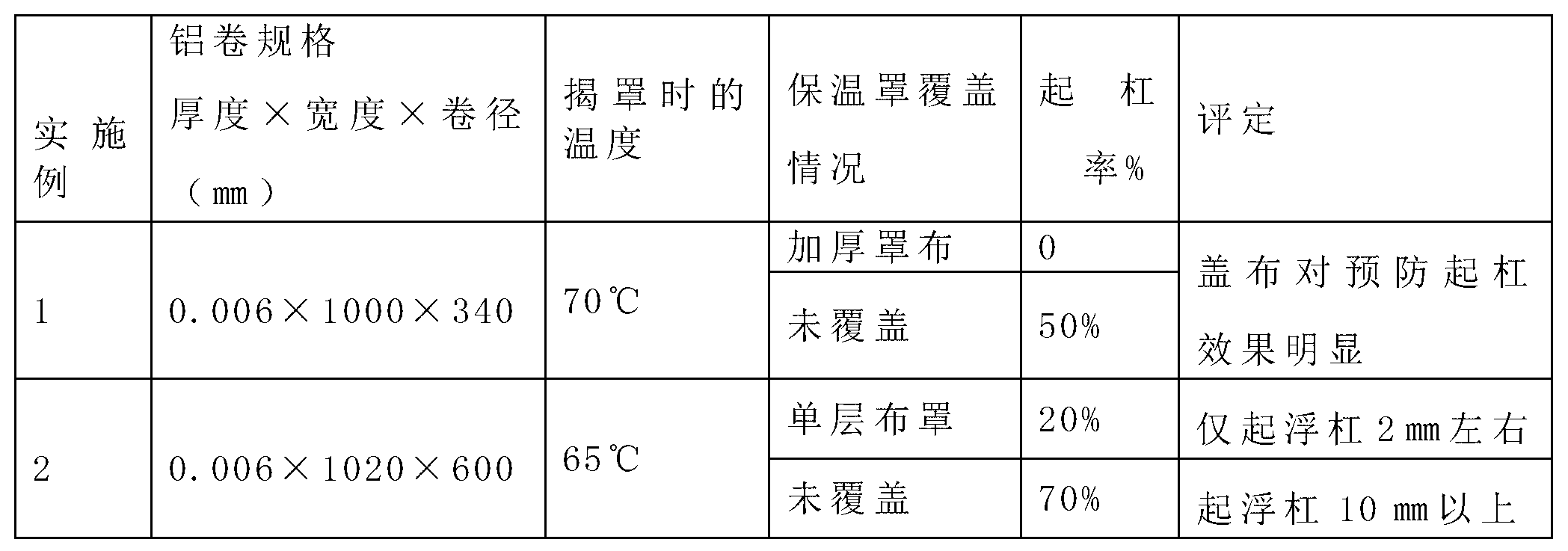

[0011] The following table is a comparison of the effect of covering the protective cover of the present invention after the aluminum coil is out of the furnace in different seasons (winter (Example 1) and summer (Example 2)) at room temperature.

[0012]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for preventing a double-zero aluminum foil from rebounding after tapping off, which comprises the following steps of: placing a high-temperature tapped aluminum coil on the ground; covering the aluminum coil with a thermal-insulating cover; and slowly cooling the aluminum coil to the required temperature. In winter with lower outdoor temperature, a thickened thermal-insulating cover is covered for keeping warm. At other seasons, a single-layer thermal-insulating cover is adopted. The single-layer thermal-insulating cover is made of a piece of single-layer high-temperature resisting cotton canvas. The thickened thermal-insulating cover is made of a cotton canvas cover filled with an asbestos material. According to the method, the phenomena of the uneven cooling caused by an ultrahigh cooling speed under the condition of exposing the high-temperature tapped aluminum coil in air, the aluminum coil rebounding caused by concentration of internal stress and the internal wrinkling are reduced. The problem of low use efficiency of a furnace, caused by a process of slowly cooling the double-zero aluminum foil in the furnace, is solved. The method is simple and practical.

Description

technical field [0001] The invention belongs to the technical field of nonferrous metallurgical processing, and in particular relates to a method for preventing cracking by slow cooling at low temperature outside a high-temperature annealed aluminum foil furnace. Background technique [0002] Double-zero aluminum foil generally refers to aluminum foil with a thickness of less than 0.009mm. Because of its light-shielding, fresh-keeping, anti-corrosion and other properties, it is widely used as lining materials in cigarettes, food, medicine, electronics and other industries. It is used together with other packaging materials such as plastics. , paper and other substrates are combined to enhance the strength of the packaging material. The aluminum foil is required to have good formability and a bright and flat surface during the compounding process. The traditional aluminum foil production process is: billet→rough rolling→rolling→finish rolling (double rolling)→slitting→anneal...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22F1/04

Inventor 刘文中贾建新

Owner JIANGSU DAYA ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com