On-site monitoring robot

A field monitoring and robotic technology, applied in manipulators, manufacturing tools, etc., can solve problems such as limited shooting range, and achieve the effect of improving buoyancy, enhancing the ability to climb over special terrain, and reducing self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

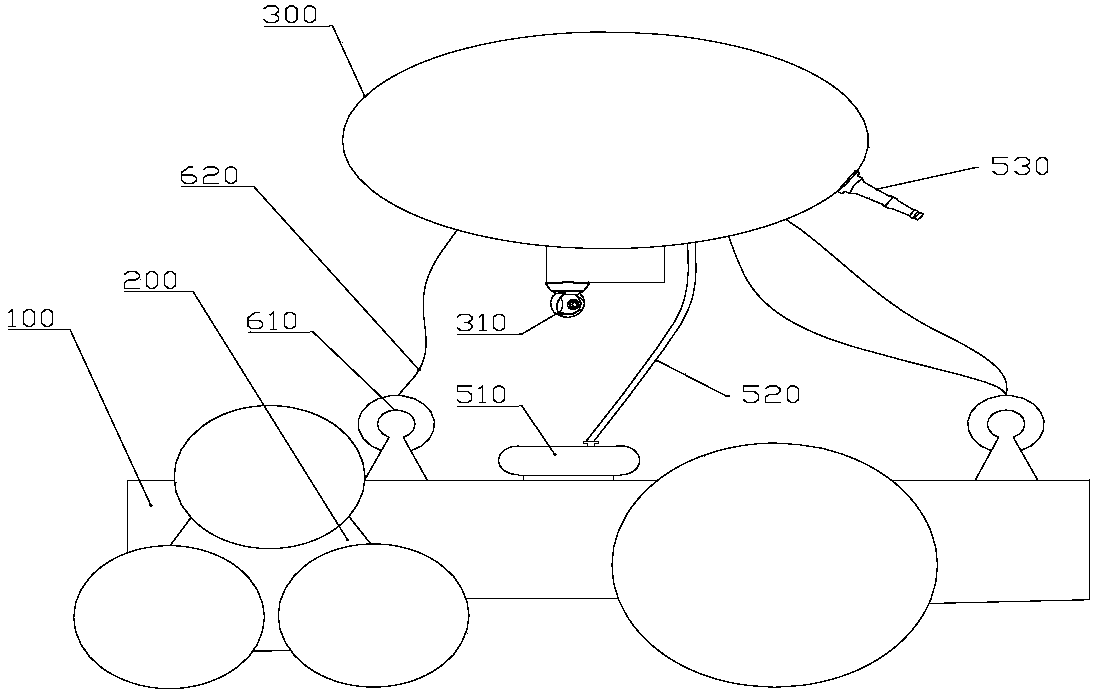

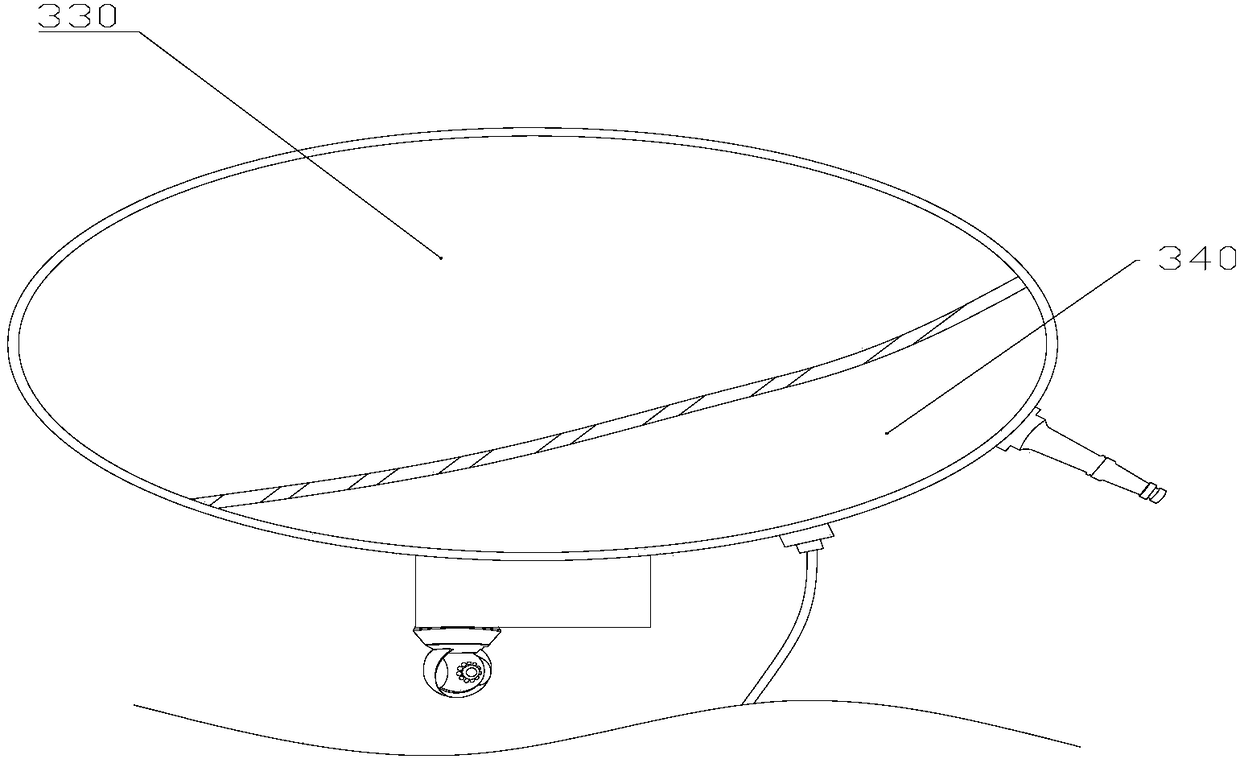

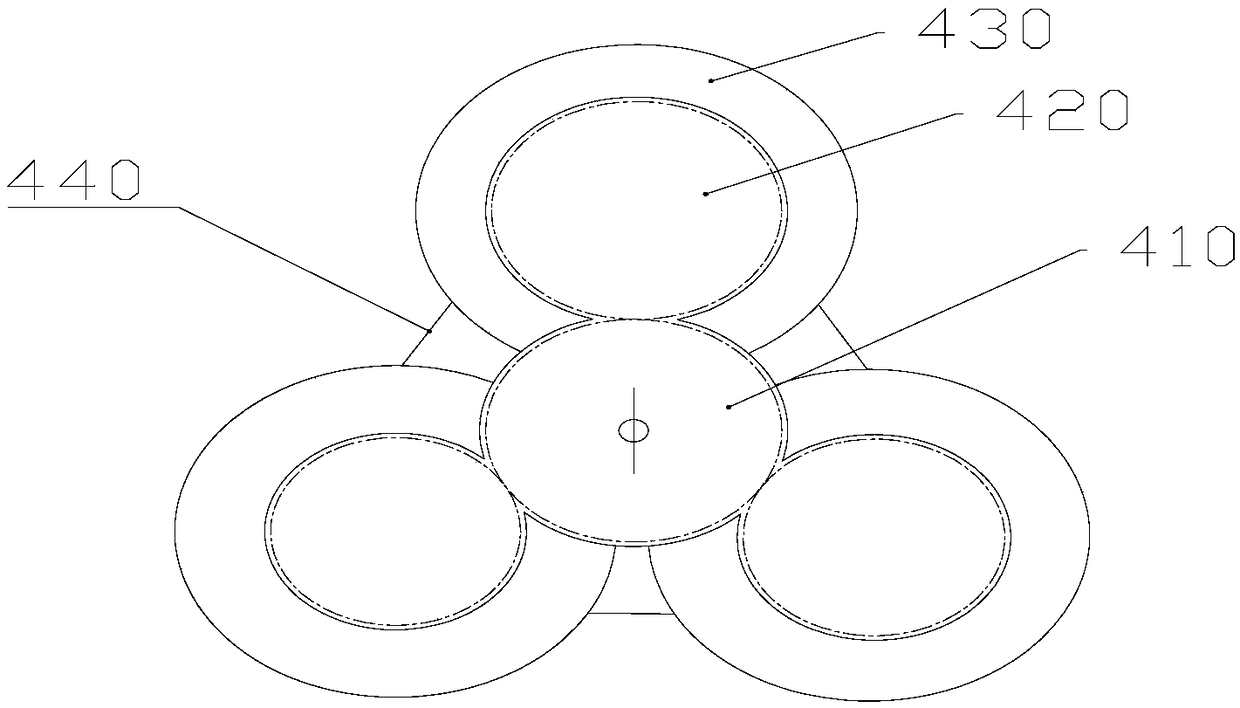

[0026] The reference signs in the accompanying drawings of the description include: base 100, walking mechanism 200, camera floating bag 300, floating chamber 330, descending chamber 340, camera 310, connecting mechanism 400, central gear 410, driven gear 420, rotating wheel 430 , center frame 440, gas storage tank 510, connecting pipe 520, fire extinguishing nozzle 530, winch 610, traction rope 620.

[0027] The embodiment is basically as attached figure 1 Shown: an on-site monitoring robot, including a base 100 , a traveling mechanism 200 installed on the bottom of the base 100 , a control system installed on the base 100 , a camera floating bag 300 and a connecting mechanism 400 .

[0028]The control system includes a controller, a power unit, a steering unit, a camera angle adjustment unit and a wireless communication unit. The power unit is used to receive the travel signal sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com