Aluminum alloy substrate used for magnetic disc, and method of manufacturing the same

A technology for aluminum alloy substrates and magnetic disks, applied in the direction of the magnetic recording layer, the base layer of the recording layer, etc., can solve the problems of flatness deterioration, substrate deformation, plating surface roughening, etc., and achieve the purpose of suppressing the deterioration of flatness and crystal effect of grain coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

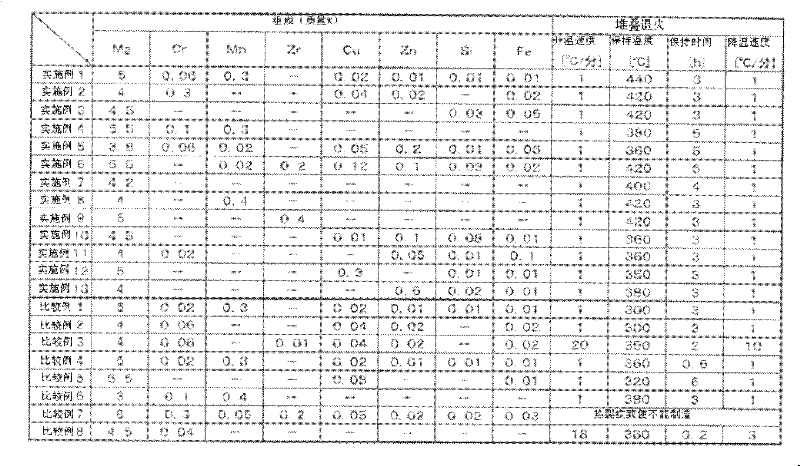

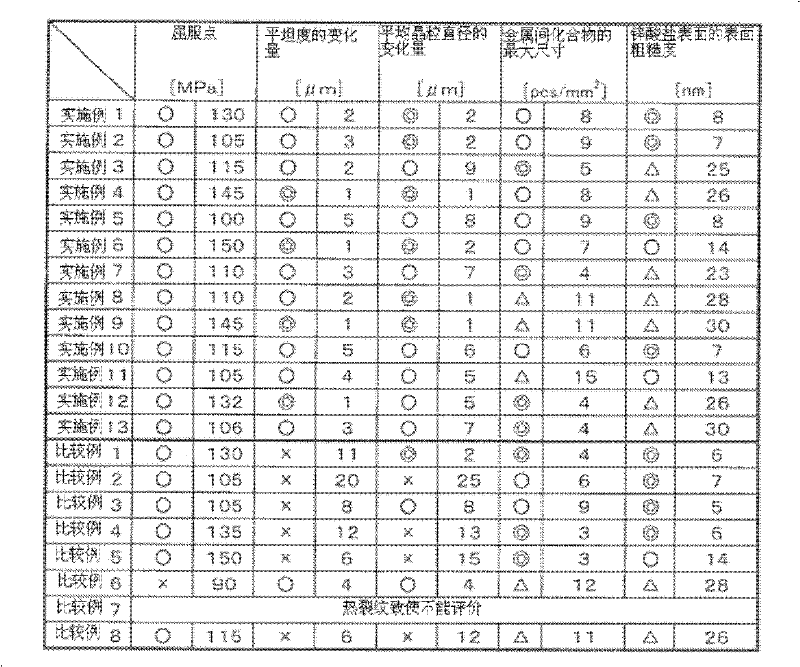

[0042] First, a first embodiment of the aluminum alloy substrate for a magnetic disk of the present invention will be described.

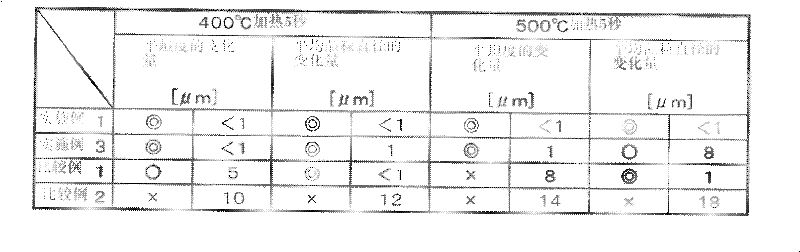

[0043] Change in flatness before and after heating at 500° C. for 10 seconds in the aluminum alloy substrate for a magnetic disk according to the first embodiment, which contains Mg at 3.5 mass % or more and 6 mass % or less, and the balance is composed of Al and unavoidable impurities 5 μm or less, and the change amount of the average crystal grain diameter before and after heating at 500° C. for 10 seconds was 10 μm or less.

[0044] Here, the aforementioned "heating at 500° C. for 10 seconds" is, for example, a condition for simulating the sputtering of a magnetic material suitable for heat-assisted magnetic recording. Heat treatment performed by stacking and annealing (straightening annealing) the flatness-corrected aluminum alloy substrates for magnetic disks of the present invention. Therefore, "before and after heating at 500° C. for 10 sec...

no. 2 approach

[0064] Next, a second embodiment of the aluminum alloy substrate for a magnetic disk of the present invention will be described.

[0065] The aluminum alloy substrate for a magnetic disk according to the second embodiment contains Mg at 3.5 mass % or more and 6 mass % or less, and contains Cr at 0.05 mass % or more, Mn at 0.05 mass % or more, and Zr at 0.05 mass % or more At least one selected, the balance consisting of Al and unavoidable impurities, the amount of change in flatness before and after heating at 500°C for 10 seconds is 5 μm or less, and the average grain size before and after heating at 500°C for 10 seconds The amount of change in diameter is 10 μm or less.

[0066] In addition, the aluminum alloy substrate for a magnetic disk according to the second embodiment contains 3.5% by mass to 6% by mass of Mg, and the balance is composed of Al and unavoidable impurities, and the flatness before and after heating at 500° C. for 10 seconds The amount of change in degree...

no. 3 approach

[0071] Next, a third embodiment of the aluminum alloy substrate for a magnetic disk of the present invention will be described.

[0072] The aluminum alloy substrate for a magnetic disk according to the third embodiment contains Mg at 3.5 mass % to 6 mass %, Cr at 0.05 mass % to 0.3 mass %, and Mn at 0.05 mass % to 0.5 mass % , and Zr is at least one selected from the group of 0.05% by mass to 0.5% by mass, and contains the group of Cu of 0.01% by mass to 0.2% by mass and Zn of 0.01% by mass to 0.4% by mass At least one selected from among, the balance is composed of Al and unavoidable impurities, and among the unavoidable impurities, Si is limited to 0.03 mass % or less, Fe is limited to 0.05 mass % or less, and heated at 500 ° C The amount of change in flatness before and after 10 seconds was 5 μm or less, and the amount of change in average grain diameter before and after heating at 500° C. for 10 seconds was 10 μm or less.

[0073]In addition, the aluminum alloy substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com