Method for dehydrogenating low-carbon stainless steel in refining furnace

A refining furnace and stainless steel technology, applied in the field of dehydrogenation of low-carbon stainless steel in the refining furnace, to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment is carried out on a 90-ton double-station VOD refining furnace. Two bottom blowing gas supply devices are installed at the bottom of the ladle used. The maximum flow rate of single bottom gas supply is 600L / min, and the highest vacuum degree of VOD is 80Pa.

[0019] The smelted steel type TGOG13Cr-2, the mass percentage of the chemical composition of the finished steel type is shown in Table 1:

[0020] Table 1

[0021] the element

C%

Si%

Mn%

P%

S%

standard

≤0.030

0.15-0.40

0.50-0.65

≤0.018

≤0.008

the element

Cr%

Ni%

Mo%

V%

N%

standard

12.50-14.50

4.00-6.00

1.90-2.10

0.07-0.11

≤0.050

[0022] The steps of this embodiment are dehydrogenation by blowing argon at the bottom of the ladle under vacuum after carbon deoxidation and reduction under vacuum, and the steps are characterized by:

[0023] 1. In the ea...

Embodiment 2

[0037] This embodiment is carried out on a 90-ton double-station VOD refining furnace. Two bottom blowing gas supply devices are installed at the bottom of the ladle used. The maximum flow rate of single bottom gas supply is 600L / min, and the highest vacuum degree of VOD is 80Pa.

[0038] The smelted steel grade TP316LN, the mass percentage of the chemical composition of the finished steel grade is shown in Table 2:

[0039] Table 2

[0040] the element

C%

Si%

Mn%

P%

S%

standard

≤0.020

0.40-0.65

1.00-1.80

≤0.025

≤0.005

the element

Cr%

Ni%

Mo%

Cu%

N%

standard

16.80-17.80

12.00-13.00

2.20-2.80

≤0.10

≤0.050

[0041] The steps of this embodiment are dehydrogenation by blowing argon at the bottom of the ladle under vacuum after carbon deoxidation and reduction under vacuum, and the steps are characterized by:

[0042] 1. In the early ...

Embodiment 3

[0056] This embodiment is carried out on a 90-ton double-station VOD refining furnace. Two bottom blowing gas supply devices are installed at the bottom of the ladle used. The maximum flow rate of single bottom gas supply is 600L / min, and the highest vacuum degree of VOD is 80Pa.

[0057]The smelted steel grade is 304L, and the chemical composition (mass percentage) of the finished steel grade is shown in Table 3:

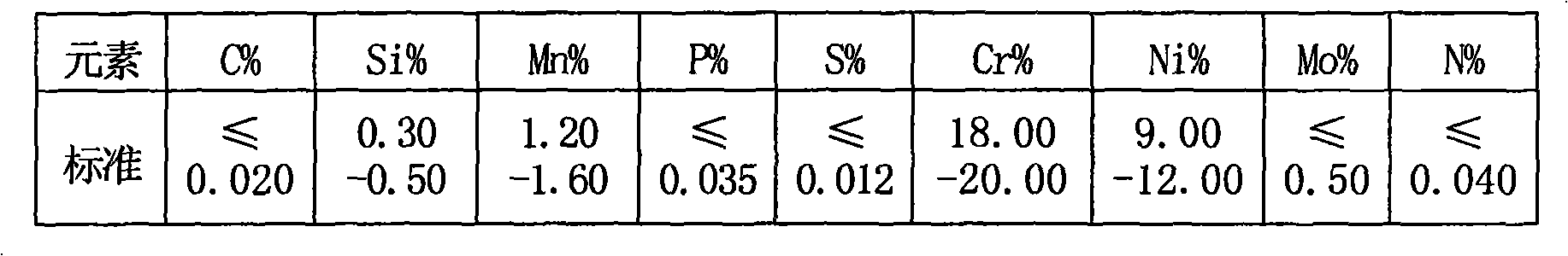

[0058] table 3

[0059]

[0060] The steps of this embodiment are dehydrogenation by blowing argon at the bottom of the ladle under vacuum after carbon deoxidation and reduction under vacuum, and the steps are characterized by:

[0061] 1. In the early stage of molten steel treatment, use high-carbon deoxygenation boiling dehydrogenation molten steel under high vacuum to obtain the initial chemical composition mass percentage in VOD refining furnace:

[0062] C 0.31; Si 0.10; Mn 1.45; P 0.022; S 0.011; Cr 18.17; Ni 9.63;

[0063] Mo 0.02; N 0.1810; H 0.00023; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com