Copolymer having dithio structure-containing annular groups, its preparation method and application

A technology of cyclic groups and copolymers, which is applied to copolymers with cyclic groups containing disulfide structures and its preparation and application fields, which can solve the problem of uneven grafting and the inability to achieve effective chemical grafting stabilizers. methods, low grafting efficiency, etc., to achieve the effects of expanding dynamic volume, improving salt resistance and hydrophilic performance, and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

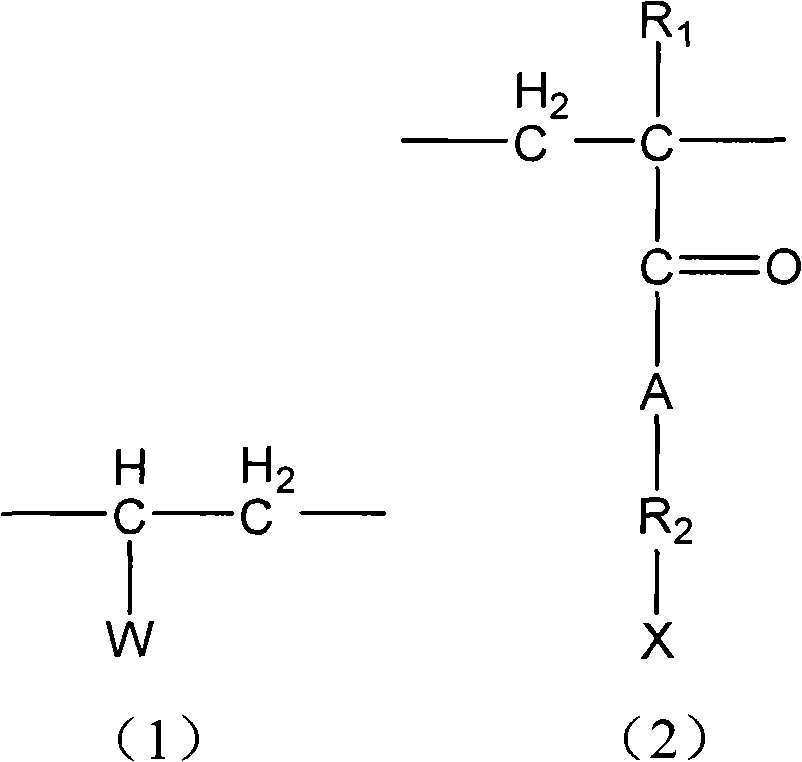

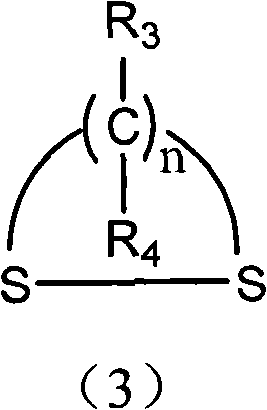

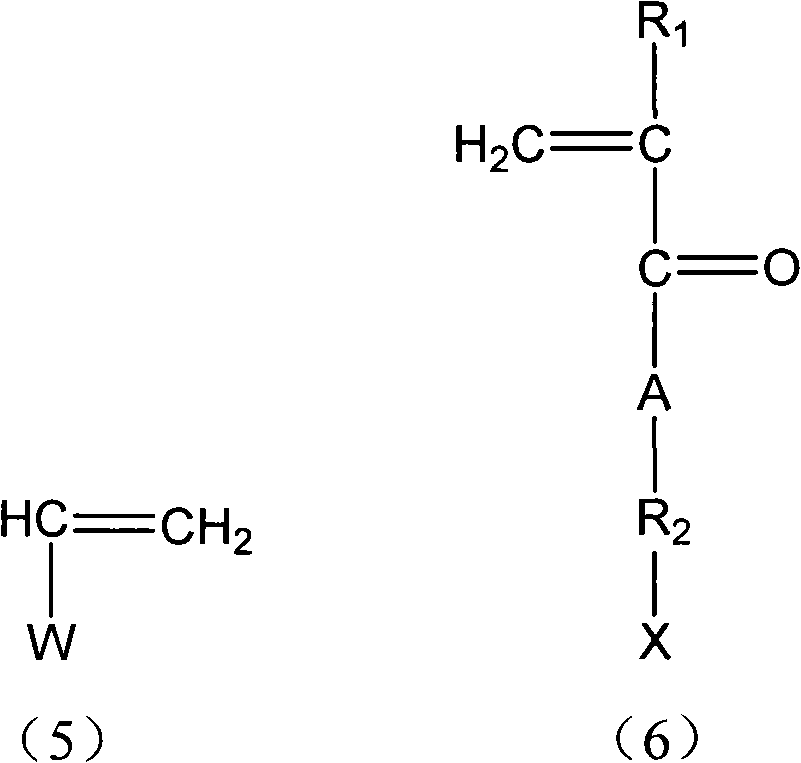

[0035] According to the present invention, the preparation method of the polymer having a cyclic group containing disulfide structure comprises: in the presence of an initiator, the compound shown in formula (5) and the compound shown in formula (6) are carried out aqueous solution polymerization,

[0036]

[0037] In formula (5), W is as defined above in the present invention, in formula (6), R 1 , R 2 , A and X are as defined above in the present invention.

[0038]According to the method of the present invention, wherein, the weight ratio of water, the compound shown in the formula (5), the compound shown in the formula (6) and the initiator can be 1000: (80-450): (20-50): ( 1-3), preferably, the weight ratio of water, the compound shown in the formula (5), the compound shown in the formula (6) and the initiator can be 1000: (100-260): (20-40): (1-3).

[0039] According to the method provided by the present invention, the initiator can be selected from various conven...

preparation Embodiment 1

[0063] This example is used to illustrate the compound with a cyclic group containing a disulfide structure provided by the present invention and its preparation method.

[0064] In a three-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, add 1 part of thioctylamine (scientific name: 6,8-dithioctylamine), 10 parts of solvent toluene and 0.01 part of polymerization inhibitor agent hydroquinone, heated to 60°C to dissolve it completely, and then added 2 parts of methacrylic acid and 0.1 part of concentrated sulfuric acid (98% by mass concentration) in sequence. First heat and reflux for about 3 hours, and then install a water separator for azeotropic dehydration. After separating 0.7 parts of water, the temperature in the three-necked flask was maintained at 120°C. When it was observed that the desorption amount was equivalent to the theoretical value (1 part of water), the reaction was stopped, the temperature was lowered to room temperature, and un...

preparation Embodiment 2

[0068] This example is used to illustrate the compound with a cyclic group containing a disulfide structure provided by the present invention and its preparation method.

[0069] In a three-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, based on the amount of the substance, after adding 0.01 part of the polymerization inhibitor hydroquinone, add 1 part of thioctyl alcohol (scientific name: 6,8-dithioctyl alcohol) in sequence. Octanol), 1.2 parts of triethylamine, 10 parts of toluene solvent, warm up to 50°C, then add 2 parts of methacryloyl chloride into the dropping funnel (the molar ratio of the three is 1:1.2:2, methacryloyl chloride Excess), add dropwise for about 1 hour, and keep warm at 50°C for 8 hours after the dropwise addition is completed. After the reaction, filter the salt generated by the reaction, distill under reduced pressure, remove the solvent and excess acid chloride, then pour the product into a beaker, wash off hydroquinone a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com