Olefin polymerization catalyst and preparation method thereof

A technology for olefin polymerization and catalysts, applied in the field of olefin polymerization catalysts and their preparation, can solve the problems of unfavorable production of polymers, poor hydrogenation sensitivity of catalysts, etc., and achieve the effect of suitable molecular weight distribution and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

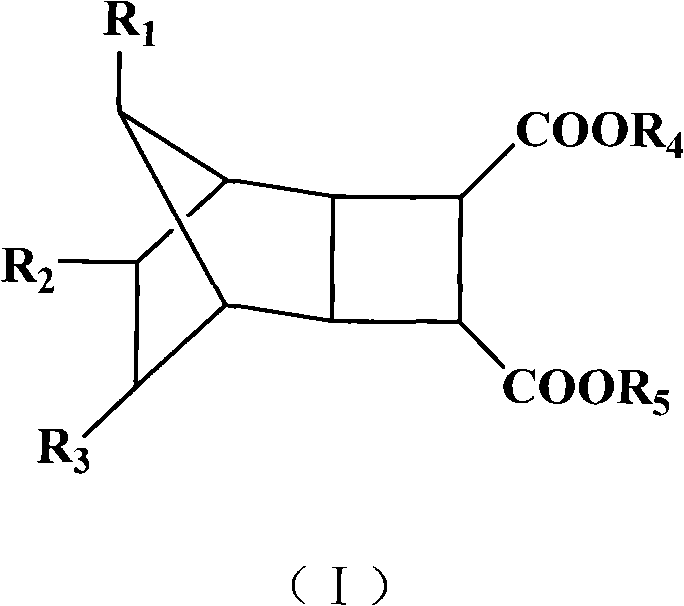

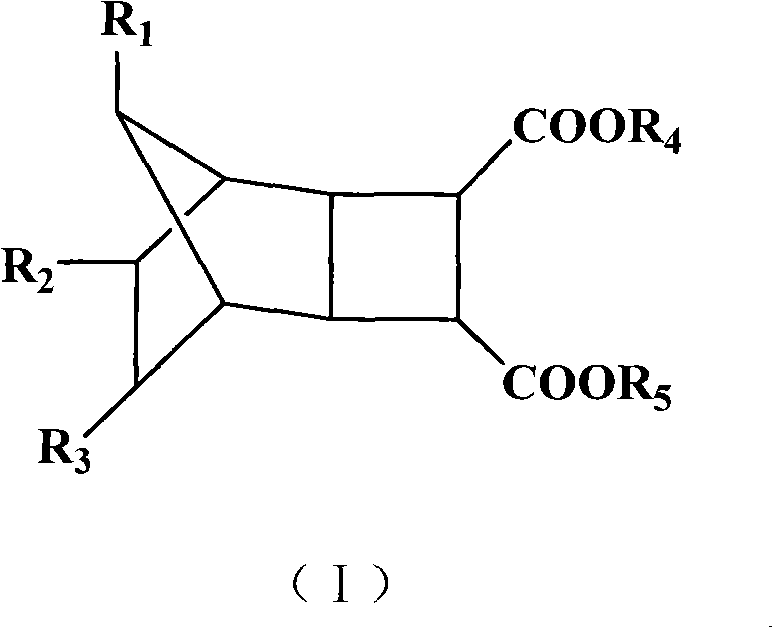

[0042] 1. Synthesis of bicyclo[2,2,1]-2,3-α,β-diethyl succinate electron donor

[0043] Add 1.17g of maleic anhydride, 5.00g of norbornene and 0.58g of benzophenone in 150mL of dichloromethane, and irradiate with ultraviolet light for 12 hours while stirring; add 30mL of ethanol and 0.1g of p-toluenesulfonate after removing the solvent acid, heated to reflux at 100°C for 48 hours; removed the solvent again, extracted with 3×50mL ether, washed with saturated sodium bicarbonate solution, and dried over anhydrous magnesium sulfate; filtered to remove the ether to obtain 1.67g colorless viscous bicyclo[2, 2,1]-Diethyl 2,3-[alpha,[beta]succinate.

[0044] through 1 H NMR (CDCl 3 , 300MHz) analysis results: δ1.30-1.55 (m, 12H, 6CH 2 , 6CH 3 ); δ2.04(m, 2H, CH); δ3.14(m, 2H, CH); δ4.12(m, 4H, CH 2 ).

[0045] 2. Preparation of solid titanium catalyst

[0046] Add 5.0 g of anhydrous MgCl to the glass bottle reactor fully replaced by high-purity nitrogen 2 , 50 mL of toluene, 6...

Embodiment 2

[0056] In addition to changing the addition of bicyclo[2,2,1]-2,3-α,β-diethyl succinate and diisobutyl phthalate to 3mmol, other processes and operations are consistent with the examples 1, the results are shown in Table 1. Solid content titanium (wt%) 2.1, specific surface area 256m 2 / g. Catalyst particle size (D50): 19.84 microns, particle size distribution (SP): 0.9. SEM showed that the particles were spherical in shape.

Embodiment 3

[0058] In addition to changing the amount of bicyclo[2,2,1]-2,3-α,β-diethyl succinate and diisobutyl phthalate to 0.4mmol and 7.6mmol, other processes and operations Same as Example 1, the results are shown in Table 1. Solid content titanium (wt%) 2.2, specific surface area 255m 2 / g. Catalyst particle size: D50: 22.8 microns, particle size distribution (SP): 1.2. SEM showed that the particles were spherical in shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com