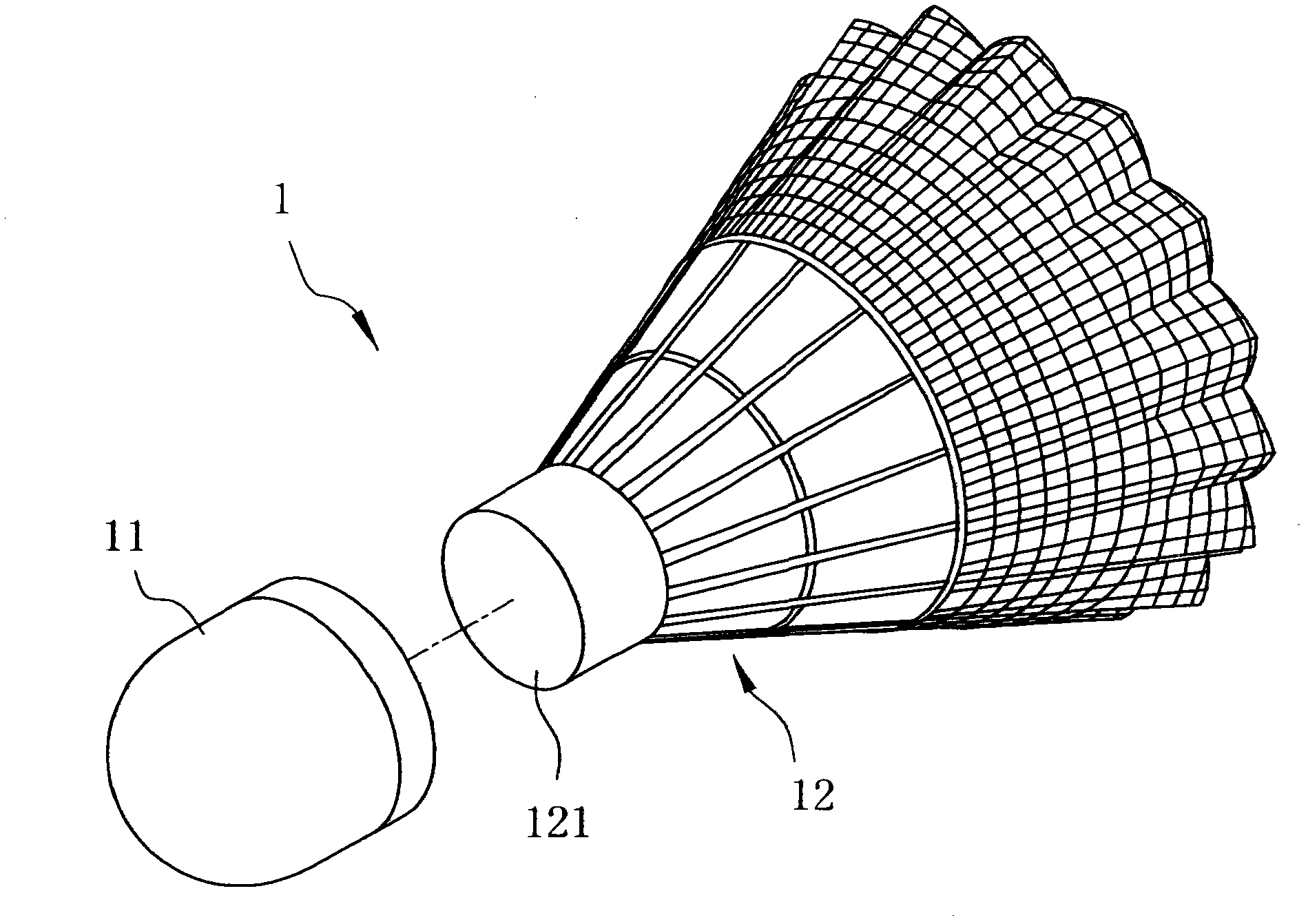

Elaborate goose feather shuttlecock and production method thereof

A manufacturing method and technology of goose feathers, applied in the direction of sports accessories, etc., can solve the problems of strength, speed reduction, weight increase, weak counterattack strength, etc., and achieve the effect of high quality and reduced manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

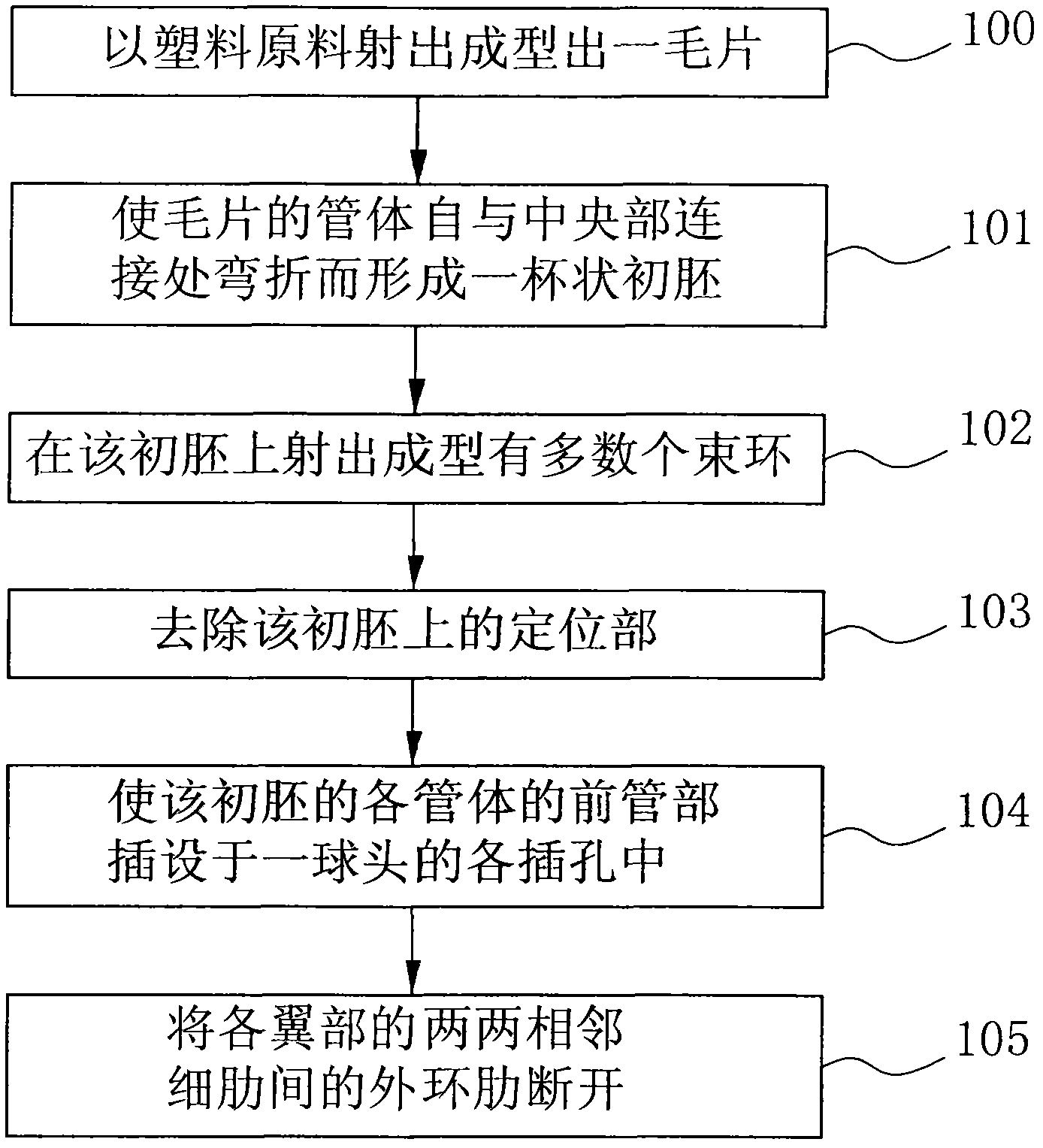

[0043] refer to figure 2 , is a preferred embodiment of the manufacturing method of the Seiko-type goose feather shuttlecock of the present invention, comprising the following steps:

[0044] Cooperate with reference figure 2 , 3 Firstly, in step 100, a wool sheet forming mold 21 is first prepared, and the wool sheet forming mold 21 has a mold cavity 211, and then plastic material is injected into the mold cavity 211 to produce a mold as Figure 4 The wool piece 3 shown has a central part 31 , a plurality of tubes 32 extending from the central part 31 at intervals, and a plurality of wing parts 33 respectively formed at the ends of the tubes 32 . Each tube body 32 has a front tube part 321, and a connection part 322 connected between the front tube part 321 and the wing part 33, in the present embodiment, the tube body 32 is illustrated with 16, But not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com