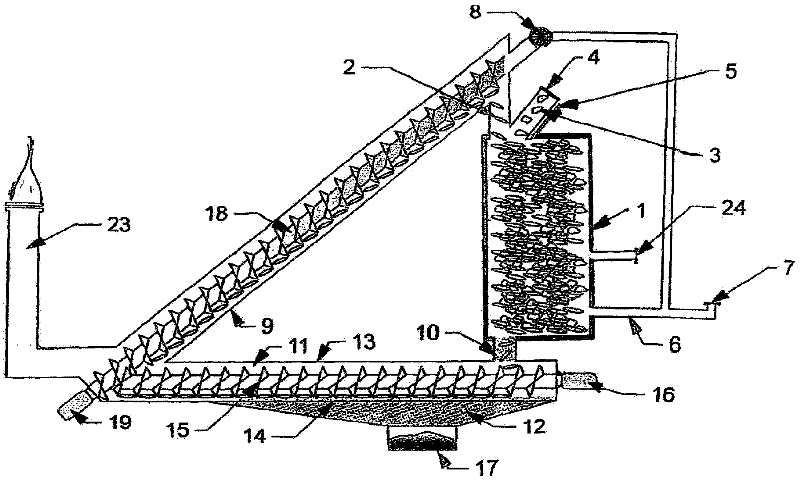

Novel method for pyrogasification of organic waste

A technology for cracking gasification and organic waste, applied in combustion methods, incinerators, biofuels, etc., and can solve the problems of incomplete and insufficient cracking of condensable gas and tar, poor cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

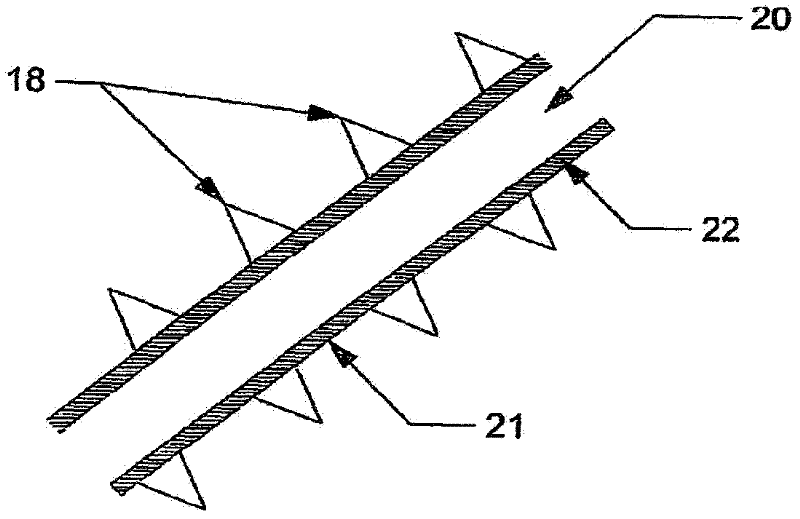

[0025] These ring coils travel in the stationary shaft furnace in the same direction as the material to be cracked.

[0026] The choice of a toroid rather than a bead is critical in the present invention: the toroid has the highest ratio of heat exchange surface area to weight, which is important because the toroid is in a furnace It provides the best possible yield both when heated and when the energy is recovered and transferred to the material to be cracked. For example, a traditional heat-resistant steel ball (that is, a spherical shape with a diameter of 40mm) weighs 261.4 grams and has a diameter of 5026.55mm 2 exchange surface. For a weight substantially equal to 262 grams, it is possible to use a toroid with an outer diameter of 60 mm and an inner diameter of 24 mm, resulting in a cross-section of 18 mm. The exchange surface of this toroid will be 7461.42mm 2 . For a comparable weight of steel, the exchange surface area ratio between the toroid and the sphere is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com