Concrete composition using blast furnace slag composition

A technology for concrete composition and blast furnace slag, which is applied in cement production and other directions, can solve the problems of decreasing and increasing the compressive strength of the hardened body, unable to ensure workability, and difficult to suppress the drying shrinkage of the hardened body, etc. The effect of suppressing drying shrinkage and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

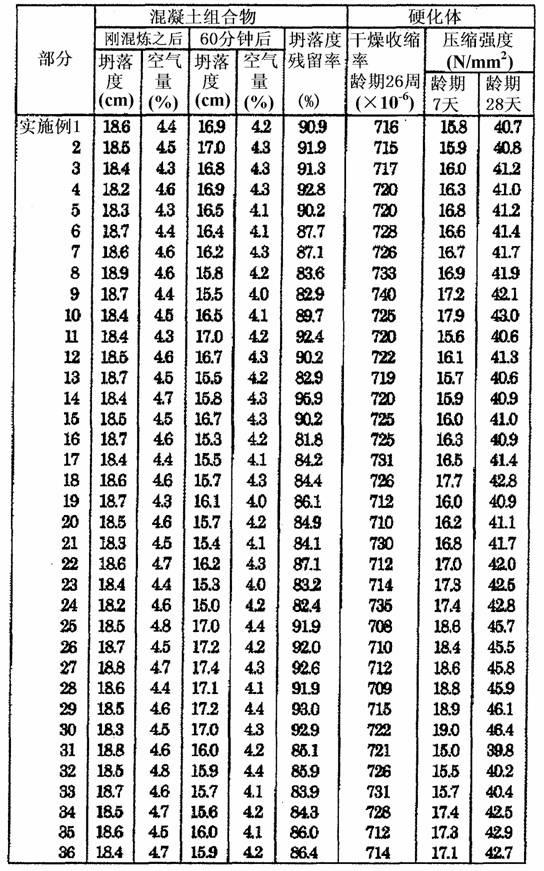

Embodiment 1~36

[0068] Under the blending conditions recorded in Table 3, each specified amount of mixing water (tap water), blast furnace slag composition, and fine aggregate (river sand produced in the Oi River system, density=2.58) was dropped into a 50-liter pot-type forced mixer. g / cm 3 ), in addition to adding a specified amount of mixed materials such as cement dispersant, drying shrinkage reducing agent, and expansion material, and further adding an air volume regulator (AE agent manufactured by Takemoto Oil Co., Ltd., trade name AE-300), kneading for 45 seconds. Finally, put in a specified amount of coarse aggregate (crushed stone from Okazaki, density = 2.68g / cm 3 ), mixed for 60 seconds to manufacture a concrete composition with a target slump of 18 ± 1 cm and a target air volume of 4.5 ± 1% water / blast furnace slag composition mass ratio of 45% or 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com