Device for monitoring environmental parameter in test box used in ultrasonic flaw detector calibration device

A verification device, ultrasonic flaw detection technology, applied in the direction of measuring device, general control system, material analysis using sound wave/ultrasonic wave/infrasonic wave, etc., can solve the problems of no unified standard, inconvenient use and operation, poor use effect, etc. The effect of flexible method, simple operation and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

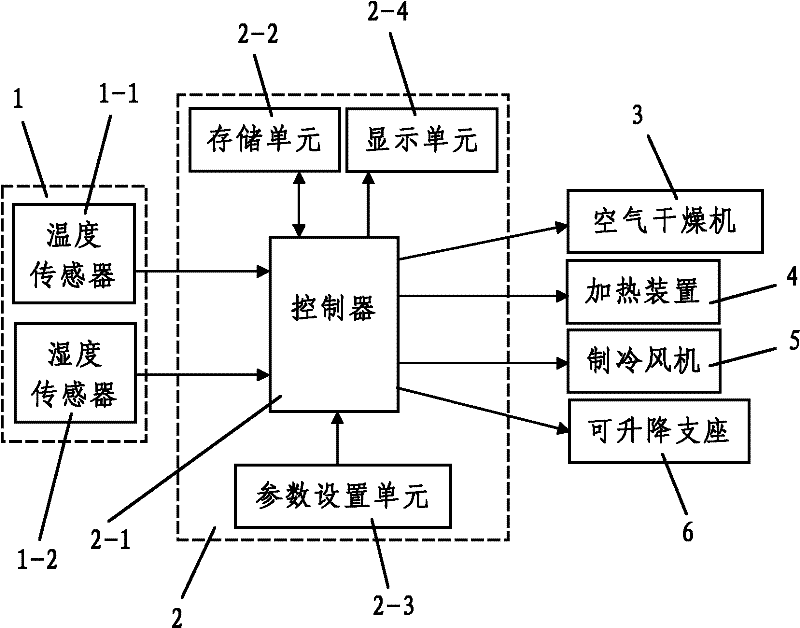

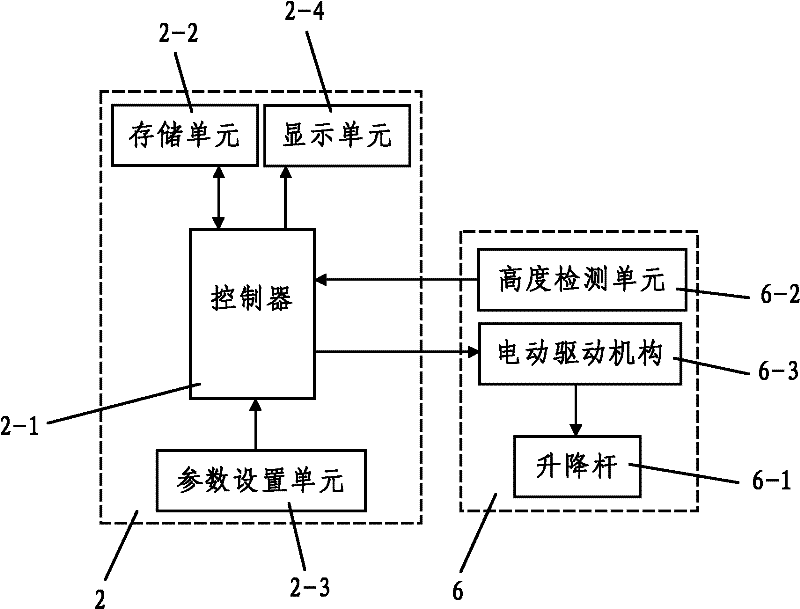

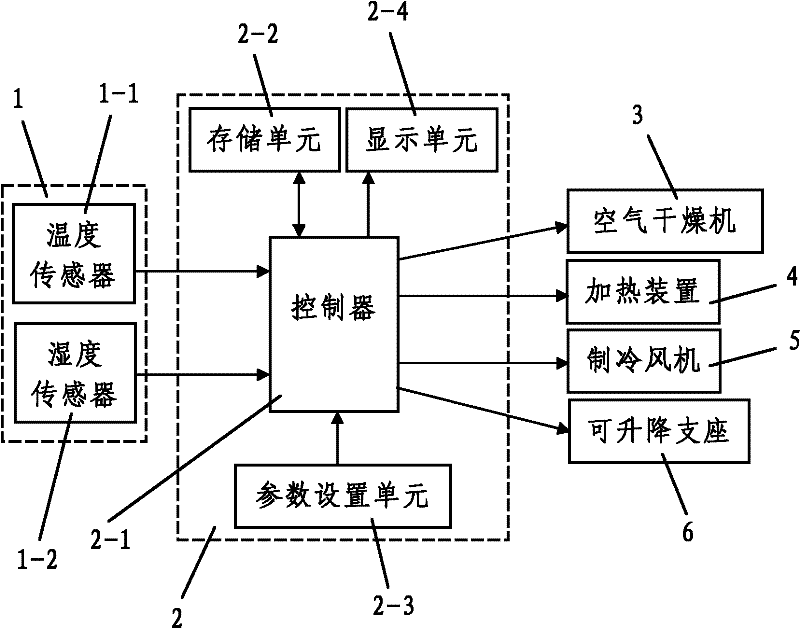

[0029] like figure 1 , figure 2 As shown, the present invention includes an environmental parameter detection unit 1, a control system 2, an air dryer 3 and a heating device arranged on the inner wall of the test chamber and carrying out real-time detection of relevant environmental parameters inside the test chamber. 4 and a cooling fan 5, the control system 2 includes a storage unit 2-2, a parameter setting unit 2-3, a display unit 2-4, and a parameter setting unit 2-2 internally storing an environmental parameter database of standard environmental parameters for ultrasonic flaw detection of various materials. The material of the measured workpiece input by the setting unit 2-3 is matched with the environmental parameter database, and the air dryer 3, the heating device 4 and the cooling fan 5 are controlled correspondingly according to the matching result and the information detected by the environmental parameter detection unit 1 controller 2-1. The storage unit 2-2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com